Understanding the Market, Importance of Equipment

When searching for used food packaging equipment, grasp the significant savings and value these machines bring to your production line. Acquiring such equipment at a fraction of the cost of new models can significantly enhance your operation’s efficiency without compromising quality. Used packaging equipment spans a variety of types, including vacuum packers, tray sealers, and labelers, offering solutions for different packaging needs.

The global market for packaging machinery is vast and continuously evolving, with the food industry being a substantial segment. Efficient and reliable packaging equipment plays a pivotal role in the food manufacturing process, directly impacting product safety, shelf life, and presentation. Recognizing the value of properly selected and maintained used equipment can be the key to achieving operational excellence and sustainability in the competitive food industry.

Beth-El Machinery Ltd. stands out in this arena, offering premiere packaging solutions designed to meet the highest standards of hygiene and efficiency, crucial for food products. Their machines are built to ensure that even the most sensitive products are packaged in a manner that prolongs shelf life and preserves quality.

Why Consider Used Equipment?

- Cost Savings: Substantially lower purchase price compared to new ones.

- Immediate Availability: Avoids the lead time associated with new equipment orders.

- Depreciation: Slower rate compared to new machines, offering better value over time.

- Eco-friendly: Reusing equipment contributes to sustainability efforts by reducing waste.

For businesses in the food industry seeking to enhance their packaging processes, considering used equipment could offer the right balance of performance, cost-effectiveness, and timely deployment. Key to making the most of this opportunity is partnering with reputable suppliers like Beth-El Machinery Ltd., known for their high-quality food packaging solutions.

Evaluating Your Needs

When diving into used food packaging equipment, it’s like setting sail in a vast ocean. You need a good map, the right tools, and a clear destination. Let’s navigate these waters together, focusing on three critical aspects: budget considerations, types of packaging, and volume requirements.

Budget Considerations

Money talks, but it doesn’t have to shout. When considering used equipment, think smart. A shiny new machine might look appealing, but the price tag can be eye-watering. Used equipment, on the other hand, can be a treasure chest waiting to be unlocked. It offers like-new quality at a fraction of the cost. This is especially true with reputable sources like Beth-El Machinery Ltd., where high hygiene standards and efficiency meet budget-friendly solutions. The goal is to maximize value without compromising on quality or productivity.

Types of Packaging

Next, let’s talk packaging. The food industry is as diverse as the cuisines of the world. From flexible packaging for snacks to rigid containers for beverages, the right packaging can make your product stand out on the shelves. Beth-El Machinery Ltd. shines here with their Hygiene Bottle Sterilisation Machine, perfect for ensuring that sensitive products are filled and sealed in a highly sterile environment. This level of versatility and hygiene is crucial, as the type of packaging you choose should align with your product’s needs and consumer preferences.

Volume Requirements

Finally, consider your volume requirements. How much product are you planning to package daily, weekly, or monthly? This is not just about meeting current demands but also about future-proofing your business. Equipment like the Hygiene Bottle Sterilisation Machine from Beth-El Machinery Ltd. can handle between 1,000 and 15,000 bottles per hour, showcasing the importance of scalability. Whether you’re a small boutique operation or a bustling factory, selecting equipment that can grow with you is key.

In summary, when evaluating your needs for used food packaging equipment, remember:

- Budget wisely: Opt for used equipment to get more bang for your buck without sacrificing quality.

- Choose the right type of packaging: Match your packaging to your product and market needs, leveraging flexible solutions from trusted suppliers like Beth-El Machinery Ltd.

- Plan for volume: Ensure your equipment can handle your current and future production needs for seamless scalability.

As we sail from the calm waters of evaluation into the bustling ports of acquisition, the right preparation can make all the difference. Let’s set the course for the next part of our journey, where we’ll explore where to find the best-used food packaging equipment.

By keeping these considerations in mind, you’re well on your way to making informed decisions that will benefit your business in the long run.

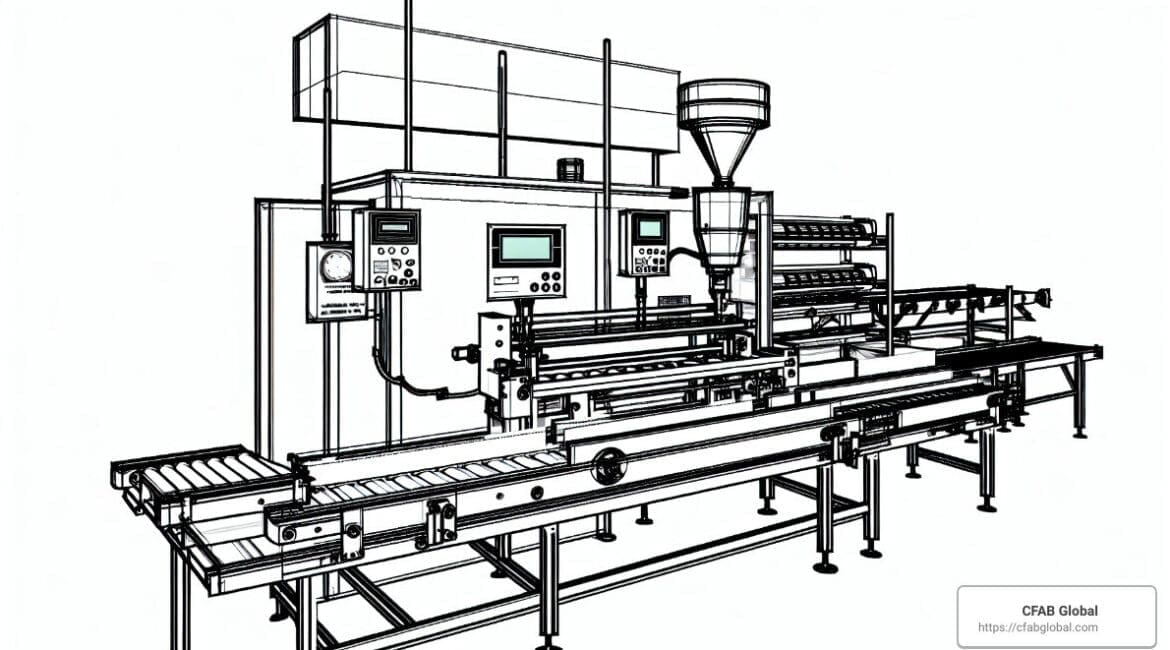

Types of Used Food Packaging Equipment

When diving into used food packaging equipment, understand the various types of machinery available and how they can serve your business needs. From slicers, dicers, and shredders to specialty equipment like juice presses and dewatering equipment, each plays a crucial role in food processing and packaging operations. Let’s explore some of the key types of equipment you might consider for your business.

Slicers, Dicers, and Shredders

URSCHEL models are renowned for their reliability and efficiency in slicing, dicing, and shredding food products. These machines can handle a wide range of food items, ensuring uniformity and quality of the cut, which is essential for consistency in food processing.

Cooking Kettles

Lee, Groen, Hamilton are leading names when it comes to cooking kettles. These kettles are designed for cooking, mixing, and storing large volumes of food products. They offer precise temperature control and are available in various capacities to suit different production needs.

Blanchers and Peelers

For preparing vegetables and fruits, blanchers and peelers from FMC, LYCO, Vanmark offer efficient solutions. These machines are designed to preserve the freshness and nutritional value of produce while ensuring they are clean and ready for further processing or packaging.

Fillers and Bottlers

Piston Fillers, Bottle Fillers, Auger Fillers are essential for accurate and efficient filling of products into containers. These machines ensure that each container is filled with the exact amount of product, reducing waste and ensuring consistency across your product line.

Can Seamers and Cappers

Sealing is a critical step in the packaging process. Angelus, Canco, Resina provide robust solutions for can seaming and capping, ensuring that products are securely sealed and ready for distribution.

Labelers and Metal Detectors

Branding and safety are paramount in food packaging. Labelers from Burt, Krones offer precision in applying labels to various types of packaging. Meanwhile, metal detectors from Goring-Kerr ensure that your products are free from any metallic contaminants, maintaining the highest standards of food safety.

Mixers and Blenders

For consistent mixing of ingredients, mixers and blenders from J.H. Day, Rietz are indispensable. These machines ensure that your food products have the right texture and consistency, which is crucial for both quality and customer satisfaction.

Specialty Equipment

Juice Presses, Dewatering Equipment, Freshcut Processing Equipment cater to specific needs within the food processing industry. Whether you’re looking to extract juice, remove excess water, or prepare fresh-cut produce, there’s specialized equipment designed to meet these needs efficiently.

For businesses seeking innovative and hygienic food packaging solutions, Beth-El Machinery Ltd. offers a range of equipment tailored to the food industry’s needs. Their solutions ensure that your food products are processed and packaged to the highest standards, maintaining quality and safety from production to the consumer.

By understanding the types of used food packaging equipment available, you can better assess which machinery will best suit your production requirements and help you achieve your business goals. Investing in the right equipment can significantly enhance your operation’s efficiency, quality, and profitability.

In the next section, we’ll explore where to find the best-used food packaging equipment, guiding you through the process of sourcing reliable machinery that meets your specific needs.

Where to Buy Used Food Packaging Equipment

Finding the right used food packaging equipment can feel like searching for a needle in a haystack. But don’t worry, we’ve got you covered. Here’s a straightforward guide to finding the equipment that fits your needs without breaking the bank.

Online Marketplaces

The internet is your oyster when it comes to sourcing used food packaging equipment. Online marketplaces are bustling hubs where you can find a wide range of machinery from sellers around the globe. Websites like eBay, Alibaba, and even specialized industrial equipment platforms offer listings for various types of packaging machinery. Here’s what you need to keep in mind:

- Check the Seller’s Reputation: Look for sellers with high ratings and positive feedback.

- Inspect the Equipment Virtually: Many sellers provide videos or detailed photos. Use these to gauge the condition of the machinery.

- Shipping and Handling: The size and weight of industrial equipment can make shipping costly. Factor this into your budget.

Direct from Manufacturers

Sometimes, the best deals come straight from the source. Manufacturers often have used or refurbished equipment available at a fraction of the cost of new machinery. This option can be particularly appealing because:

- Warranty: Some manufacturers offer a warranty on refurbished equipment.

- Support: Buying directly can come with ongoing support and access to spare parts.

When looking for food packaging or food processing solutions, don’t forget to check out Beth-El Machinery Ltd. They offer custom processing lines and equipment, tailored to your needs with the reliability and support you’d expect from a leading manufacturer.

Refurbishment Specialists

Refurbishment specialists breathe new life into used equipment, ensuring it meets all operational standards before resale. This option is ideal for those who want the confidence of a thoroughly inspected and repaired machine. Here’s why refurbishment specialists can be a great source:

- Quality Assurance: Refurbished equipment often undergoes rigorous testing to ensure it operates like new.

- Customization: Some specialists can modify equipment to suit your specific requirements.

- Support: Post-sale support and training on how to use the equipment effectively.

Key Takeaways:

- Explore Online Marketplaces: They are a treasure trove of options, but diligence is key.

- Consider Direct Purchases: Manufacturers like Beth-El Machinery Ltd. offer not just equipment but also expertise and support.

- Refurbishment Specialists Are Gold: They offer a middle ground between the affordability of used and the reliability of new.

As you venture into the next steps of expanding or upgrading your food packaging operations, the right equipment is out there. It’s all about knowing where to look and asking the right questions. With this guide, you’re well on your way to securing the machinery that will take your business to the next level. Stay tuned as we delve into ensuring the quality and reliability of your used food packaging equipment in the upcoming section.

Ensuring Quality and Reliability

When you’re in the market for used food packaging equipment, ensuring that you’re getting machinery that is not only functional but reliable over time is crucial. This part of the guide will focus on inspection tips, maintenance history, and vendor reputation to help you make an informed purchase.

Inspection Tips

Visual Inspection: Start with a thorough visual inspection of the equipment. Look for any signs of wear and tear, such as rust, dents, or missing parts. These could be indicators of how well the equipment has been maintained.

Operational Test: If possible, see the equipment in operation. This can give you a good idea of how well it functions and if there are any noticeable issues like strange noises or vibrations.

Check Seals and Gaskets: These components are often the first to wear out and can be costly to replace. Make sure they are in good condition.

Electrical Systems: Ensure all electrical components are in good working order and meet your local safety standards. Faulty wiring or components can pose a safety risk and lead to downtime.

Maintenance History

Ask for Records: A well-maintained piece of equipment will have a log of all the maintenance and repairs it has undergone. This history can give you insight into the machine’s reliability and any recurring issues.

Regular Maintenance: Equipment that has undergone regular maintenance is likely to be more reliable. Look for signs that the previous owner has adhered to the manufacturer’s recommended maintenance schedule.

Vendor Reputation

Do Your Research: Look into the reputation of the vendor selling the equipment. Reviews, testimonials, and feedback from previous customers can provide valuable insights into their reliability and the quality of the equipment they sell.

Ask for References: Don’t hesitate to ask the vendor for references from past customers who have purchased used equipment. Speaking directly to these customers can give you a clearer picture of what to expect.

Warranty and Support: Check if the vendor offers any warranty or support services post-purchase. A vendor confident in the quality of their equipment will often provide some form of warranty or offer servicing options.

Beth-El Machinery Ltd. Solutions

When considering your options for used food packaging equipment, it’s worth looking into Beth-El Machinery Ltd. They specialize in high-hygiene bottle sterilization and filling machines, designed for sensitive products requiring long shelf-lives. Their equipment is built with a focus on flexibility and high hygienic standards, making them a reliable choice in the food packaging industry.

The goal is to find equipment that meets your needs while ensuring that it will serve your business reliably for years to come. By focusing on the visual and operational condition, maintenance history, and choosing vendors with a solid reputation, you can make a more informed decision. With this approach, you’re not just buying used food packaging equipment; you’re investing in the long-term success of your business.

In the next section, we’ll explore some frequently asked questions about purchasing used food packaging equipment to help you further in making the best choice for your needs.

Beth-El Machinery Ltd. Solutions

When looking for used food packaging equipment, understanding the options available to you is crucial. One standout provider in this space is Beth-El Machinery Ltd. Their offerings in food packaging solutions are not just robust but also tailored to meet a variety of needs in the food processing industry.

Beth-El Machinery Ltd. specializes in a range of food packaging systems. Their product line includes:

- Hygiene Rotary Filler & Capper (AFRB Series): Ideal for businesses looking for servo-driven CNC rotary filler and capper solutions. It’s designed for precision and efficiency.

- Bottles Sterilisation Machine (ASB Series): This equipment is a must-have for businesses that prioritize the sterility of their bottled products.

- Hygiene Rotary Cup Filler (AFRC Series): Another servo-driven CNC solution, this rotary cap filler is perfect for businesses that deal with cupped products and require a hygienic packaging process.

- Inline Cup Filler (AFIC – Series): For businesses looking for a streamlined solution for filling cups, this inline filler offers efficiency and reliability.

Why Choose Beth-El Machinery Ltd.?

- Innovation and Precision: Their equipment is designed with the latest technology to ensure precision in every packaging process.

- Hygienic Solutions: Considering the importance of hygiene in food packaging, their machines are built to meet the highest standards.

- Versatility: Whether you’re dealing with bottles, cups, or any other container type, Beth-El Machinery has a solution tailored for your needs.

- Durability: Built to last, their machines offer a long-term solution for your packaging needs, ensuring a good return on investment.

Incorporating Beth-El Machinery’s Solutions

For businesses in the food industry looking to purchase used food packaging equipment, incorporating solutions from Beth-El Machinery Ltd. can be a game-changer. Their equipment is designed to address the common challenges faced in food packaging, offering efficiency, precision, and hygiene.

Whether you’re a small business or a large corporation, Beth-El Machinery Ltd. provides scalable solutions that can grow with your business. Their innovative approach to food packaging ensures that your products are packaged in the most efficient, hygienic, and reliable manner.

In the next section, we’ll explore some frequently asked questions about purchasing used food packaging equipment to help you further in making the best choice for your needs.

Frequently Asked Questions about Used Food Packaging Equipment

When stepping into the realm of acquiring used food packaging equipment, it’s natural to have queries. Below, we address common questions to streamline your decision-making process.

What to Look for When Buying Used Equipment?

Condition and Maintenance: Investigate the equipment’s current state and its maintenance history. Was it regularly serviced? Are there records available?

Age and Usage: Understand how old the equipment is and how intensively it has been used. This can give you insights into its remaining lifespan.

Compatibility: Ensure the equipment fits seamlessly with your existing production line. Compatibility issues can lead to additional expenses.

Brand Reputation: Opt for brands known for their durability and reliability. For instance, Beth-El Machinery Ltd. offers robust solutions that stand the test of time.

How to Assess the Condition of Used Equipment?

Visual Inspection: Start with a thorough visual examination for any signs of wear and tear or damage.

Operational Test: If possible, see the equipment in action. This can help you assess its operational efficiency and detect any issues.

Expert Opinion: Consider hiring a technician or an expert in food packaging equipment to evaluate the machine’s condition.

Documentation Review: Examine any available documents such as maintenance logs, manuals, and the original manufacturer’s specifications.

Benefits of Buying Used vs. New Equipment?

Cost-Effectiveness: The most immediate benefit is the significant savings compared to purchasing new equipment. Used machinery can often be acquired at a fraction of the cost.

Depreciation: Used equipment has already undergone most of its depreciation, making it a smarter financial investment in the long term.

Availability: Used equipment is typically available for immediate purchase and deployment, avoiding the lead times often associated with new machinery orders.

Sustainability: Opting for used equipment is an eco-friendly choice, extending the lifecycle of machinery and reducing waste.

In conclusion, purchasing used food packaging equipment can be a wise decision when done right. By carefully evaluating your needs, inspecting the equipment thoroughly, and choosing reputable brands like Beth-El Machinery Ltd., you can ensure that your investment is sound and beneficial to your operations. This approach not only saves costs but also contributes to a more sustainable industry practice. As you move forward, keep these FAQs in mind to guide your journey in securing the right equipment for your business needs.

Conclusion

In the journey of selecting the right used food packaging equipment, it’s crucial to partner with a provider that not only supplies the machinery but also ensures its longevity and reliability. That’s where CFAB Global’s Machine Reliability Program comes into play. Our program is designed with your success in mind, focusing on providing equipment that stands the test of time and continues to deliver exceptional performance.

Making informed decisions is at the heart of purchasing used food packaging equipment. It’s not just about finding the right piece of machinery; it’s about understanding how it fits into your operations, its maintenance history, and its future reliability. At CFAB Global, we take pride in our transparent process, providing detailed information and support so you can choose with confidence.

We understand that the food packaging industry is dynamic, requiring solutions that are not only efficient but also adaptable. That’s why we recommend exploring Beth-El Machinery Ltd. solutions, known for their high-quality food packaging and processing solutions. Their offerings are a testament to the innovation and reliability that we value.

Choosing the right equipment is a significant decision, and with CFAB Global, you’re not just purchasing machinery; you’re investing in a partnership. We’re here to ensure that your equipment not only meets your current needs but also supports your growth and success in the long term.

For those ready to explore the options and make an informed decision, we invite you to learn more about our offerings and how we can support your business. Discover the difference that quality, reliability, and partnership can make in your operations. Visit our food packaging machines page to get started. Together, let’s achieve success in the food packaging industry.