When it comes to creating the perfect homemade tomato sauce, having the right tomato sauce equipment is key.

Here’s a quick overview of essential items you might need:

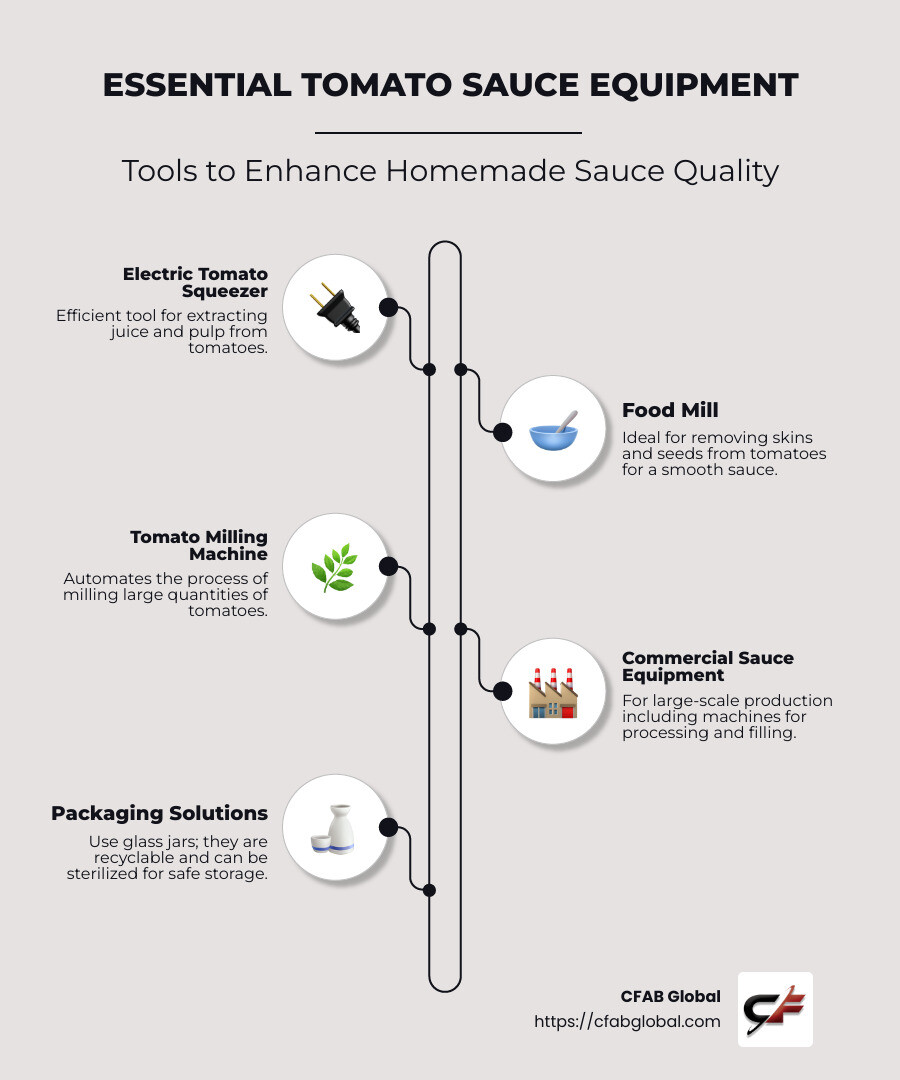

- Electric Tomato Squeezer

- Food Mill

- Tomato Milling Machine

Creating homemade sauces requires more than just tomatoes; the process involves selecting the right equipment to blend, mill, and strain those fresh ingredients into a smooth, flavorful sauce. The right tools not only simplify the process but also improve the quality and authenticity of your homemade masterpieces, taking cues from traditional Italian methods like those from imported electric tomato squeezers.

My name is Todd Cleppe, and with over 25 years of experience in manufacturing process improvement, I’ve dedicated my career to changing complex machinery challenges into efficient solutions. Welcome to our journey in optimizing and simplifying tomato sauce equipment.

Tomato sauce equipment terms to learn:

– commercial sauce making equipment

– machine for tomato processing

– sauce filling machine suppliers

Essential Tomato Sauce Equipment

Creating the perfect tomato sauce at home starts with the right tomato sauce equipment. Let’s explore what you need to make this process as smooth as your sauce.

Electric Tomato Squeezer

An electric tomato squeezer is a game-changer for anyone serious about making homemade tomato sauce. This machine, often imported from Italy, takes the labor out of squeezing tomatoes. With its .80 horsepower motor, it efficiently separates the juice and pulp from the seeds and skins, giving you a smooth sauce base with minimal effort.

One standout brand in this category is Fabio Leonardi, known for its robust, Italian-made tomato strainer machines. These machines are designed to handle large batches, making them ideal for home gardeners and sauce enthusiasts alike. They embody the essence of traditional Italian craftsmanship, ensuring that your sauce retains the authentic flavors of Italy.

Food Mill vs. Food Processor

When it comes to processing tomatoes, the debate between using a food mill and a food processor is common. Each tool has its advantages, depending on your needs.

-

Food Mill: This traditional tool is perfect for removing tomato skins and seeds, leaving you with a silky sauce. It’s particularly useful for those who prefer a hands-on approach and want to maintain the rustic authenticity of their sauce.

-

Food Processor: While great for chopping and pureeing, a food processor doesn’t separate skins and seeds. It’s more suitable for those who don’t mind a thicker texture with bits of skin and seeds.

For the purists, the food mill is often the preferred choice because it delivers a texture and flavor profile that’s closer to traditional homemade sauces.

In tomato sauce equipment, choosing between these tools often comes down to personal preference and the texture you desire in your final product. Whether you opt for the efficiency of an electric tomato squeezer or the hands-on control of a food mill, having the right equipment is crucial for achieving tomato sauce perfection.

Next, let’s explore advanced tomato sauce processing solutions that can lift your sauce-making experience to a professional level.

Advanced Tomato Sauce Processing Solutions

For those looking to lift their tomato sauce production, advanced processing solutions are key. These systems ensure efficiency, quality, and safety in every batch.

Packaging for Tomato Sauce

Packaging plays a crucial role in maintaining the freshness and flavor of tomato sauce. Glass jars are a popular choice due to their ability to preserve taste while being both recyclable and sterilizable. This eco-friendly option not only keeps your sauce safe but also reduces environmental impact.

To further improve packaging processes, BE Machinery offers innovative food packaging solutions. Their systems are designed to handle everything from filling to capping, ensuring that your sauce is packaged with precision and care. With options like the Hygiene Rotary Filler & Capper and Bottles Sterilization Machine, BE Machinery ensures that your tomato sauce is packaged in the most hygienic and efficient manner possible.

Automated Lubrication Systems

Efficient machinery is vital for large-scale tomato sauce production. Graco and Kecol provide state-of-the-art solutions for industrial fluid management. Their automated lubrication systems help keep machines running smoothly, reducing downtime and maintenance costs.

These systems ensure that all moving parts are well-lubricated, preventing wear and tear and prolonging the life of your equipment. By integrating Graco’s solutions into your production line, you can achieve seamless operations and focus on creating the best tomato sauce possible.

Incorporating advanced processing solutions like those from BE Machinery and Graco not only improves the quality of your tomato sauce but also optimizes the efficiency of your production line. These innovations provide a robust framework for producing high-quality tomato sauce with minimal effort and maximum impact.

Next, let’s dig into the cost factors involved in tomato sauce production, from transportation to centralized processing.

Cost Factors in Tomato Sauce Production

When diving into tomato sauce production, understanding the cost factors is crucial. These factors can significantly impact the final price of your product and your overall profitability.

Transportation

Transportation is a major cost driver in tomato sauce production. Moving fresh tomatoes from farms to processing facilities requires efficient logistics. The cost of fuel, labor, and vehicle maintenance adds up, making transportation a key expense. Additionally, the perishable nature of fresh tomatoes means they must be transported quickly to prevent spoilage, further increasing costs.

Centralized Processing

Centralized processing allows companies to streamline operations and reduce costs. By processing tomatoes in a single location, producers can take advantage of economies of scale. This approach reduces the need for multiple facilities and minimizes overhead expenses. However, centralized processing can also mean increased transportation costs if the processing plant is far from the tomato farms.

Non-Perishable Products

Producing non-perishable tomato products, like canned sauce, offers cost advantages. These products have a longer shelf life, reducing waste and allowing for bulk production and storage. This can lower costs in the long run, as companies don’t have to rush to sell the product before it spoils. The ability to store non-perishable products also provides flexibility in responding to market demand, allowing producers to supply tomato sauce year-round without the constraints of the growing season.

Understanding these cost factors helps producers optimize their operations and maintain competitive pricing. By efficiently managing transportation, taking advantage of centralized processing, and focusing on non-perishable products, companies can reduce costs and improve their bottom line.

Next, we’ll explore frequently asked questions about tomato sauce equipment, shedding light on the tools and techniques that make production both effective and efficient.

Frequently Asked Questions about Tomato Sauce Equipment

What equipment is used to make tomato sauce?

Making tomato sauce at home or in a commercial setting requires some essential tomato sauce equipment. A food mill is a popular choice for home cooks because it efficiently removes seeds and skins, leaving a smooth sauce. For larger batches, a tomato milling machine or an electric tomato squeezer is ideal. These machines, like those imported from Italy, offer more power and speed, processing tomatoes into sauce with minimal effort. For commercial food processing solutions, consider exploring BE Machinery’s process systems for efficient and high-quality results.

Why is tomato sauce so expensive now?

The rising cost of tomato sauce can be attributed to two main factors: transportation and centralized processing. Fresh tomatoes need to be quickly transported from farms to processing facilities, which can be costly due to fuel prices and logistics. Centralized processing helps reduce some costs by consolidating operations, but it can still lead to increased transportation expenses if the facilities are far from the farms. Additionally, the need for quick transportation to avoid spoilage adds to the overall cost, impacting the price of the final product.

Is a food mill better than a food processor for tomato sauce?

When it comes to making tomato sauce, a food mill is often preferred over a food processor. The primary advantage of a food mill is its ability to separate tomato skins and seeds from the pulp, resulting in a smoother sauce. This is particularly important for those who want a refined texture without the hassle of manually peeling and seeding tomatoes. On the other hand, a food processor can chop tomatoes quickly but doesn’t remove skins and seeds, which might not be ideal for those seeking a traditional tomato sauce consistency.

Conclusion

At CFAB Global, we understand the importance of efficiency and reliability in tomato sauce equipment. Our commitment to enhancing operational efficiency is reflected in our exclusive Machine Reliability Program. This program is designed to boost the performance and lifespan of your essential machinery, ensuring that your production processes run smoothly and without interruption.

Our Machine Reliability Program is not a one-size-fits-all solution. We work closely with each client to tailor a strategy that meets their unique needs. Whether you’re a small-scale producer or a commercial operation, our program provides the personalized analysis and cutting-edge services you need to keep your equipment in top shape.

By focusing on predictive maintenance and proactive strategies, we help you reduce costly downtime and maximize your investment in machinery. This approach not only extends the lifespan of your equipment but also ensures that your operations are consistently efficient and productive.

For those in the tomato sauce production industry, CFAB Global is your partner in achieving operational excellence. Our expertise and dedication to providing high-quality solutions make us the go-to choice for businesses looking to improve their production capabilities.

Find how our Machine Reliability Program can transform your operations and keep your equipment running at peak performance.