Introduction

When snacking is almost as routine as breathing, understanding snack trends, consumer habits, and the importance of packaging is crucial for manufacturers aiming to catch the eye and satisfy the hunger of millions. The search for the perfect snack food packaging solution can feel daunting, but it doesn’t have to be. In short, if you’re looking for ways to efficiently package your snack products, considering options like vacuum packaging, flexible pouches, and container filling tailored by reputable manufacturers like Beth-El Machinery Ltd. can significantly boost your operation’s productivity and appeal to the evolving preferences of consumers.

Snacks are not just food items anymore; they represent culture, convenience, and choices in our world. With 81% of Americans snacking at least once a day, and a considerable shift towards health-centric options amidst the convenience factor, snacks have taken a pivotal place in consumer diets and lifestyles. The essence of snacking morphed significantly during the pandemic, turning comfort foods into a source of solace and normalcy for many.

Packaging plays a monumental role not just in preserving the freshness and quality of these snacks but also in marketing them. An eye-catching design, practicality in opening and storing, along with clear nutritional information, can determine whether a snack product becomes a staple in homes or fades into obscurity on store shelves.

As snacking habits evolve and the demand for convenience, variety, and health-conscious options grows, the need for innovative and efficient snack food packaging equipment has never been more acute. Whether you are a startup looking to disrupt the snacking world or an established brand aiming to maintain momentum and meet new consumer demands, navigating the intricacies of snack food packaging is a journey well worth taking.

Packaging Requirements for Snack Foods

When it comes to keeping snacks fresh and delicious, the packaging plays a crucial role. Let’s dive into what makes snack food packaging effective:

Moisture Barrier

Moisture is one of the main enemies of snack freshness. Too much moisture can make crunchy snacks go soft, and nobody likes a soggy chip! A good moisture barrier in packaging helps keep the unwanted moisture out. This is where materials that prevent moisture from getting in are key.

Oxygen Barrier

Oxygen can cause snacks to become stale and lose their flavor. That’s why an oxygen barrier is essential. It keeps the air out and the crunch in. This is especially important for products like nuts and chips, which can quickly lose their appeal when exposed to air.

Light Barrier

Light, especially sunlight, can degrade the quality of snacks over time. It can change the flavor and even the nutritional content of food. A light barrier in packaging protects snacks from light exposure, keeping them as tasty and nutritious as the day they were packaged.

Critical Moisture Content

Understanding the critical moisture content of a snack is crucial for choosing the right packaging. This is the point at which the snack will start to lose its quality due to moisture. Different snacks have different critical moisture contents, and packaging needs to be chosen with this in mind to ensure the snack stays fresh and delicious.

To address these requirements, snack food packaging equipment must be capable of creating airtight seals and using materials that offer these barriers effectively. Beth-El Machinery Ltd. offers solutions that are designed to meet these needs, ensuring that snacks are packaged in a way that maintains their freshness, flavor, and texture. From vacuum packaging that removes air from the package to innovative materials that provide effective barriers against moisture, oxygen, and light, Beth-El Machinery Ltd. has the technology to keep snacks at their best.

By understanding and addressing these packaging requirements, snack producers can ensure their products stay fresh from the factory to the consumer’s hands. With the right snack food packaging equipment, maintaining quality and extending shelf life is not just possible—it’s a given.

As we move on to explore the types of snack food packaging machines available, the goal is to find equipment that meets these critical packaging requirements. Whether it’s vacuum packaging to remove air or machines that seal in freshness with advanced barrier materials, the right equipment makes all the difference.

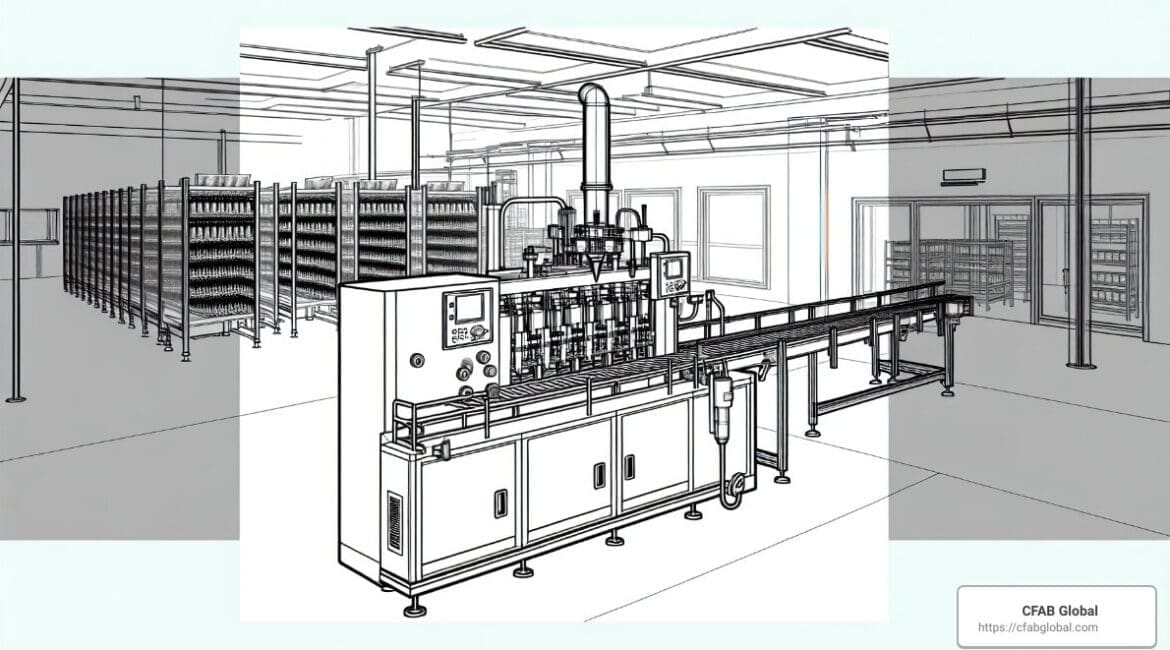

Types of Snack Food Packaging Machines

When it comes to snack food packaging equipment, the variety is as vast as the types of snacks themselves. From keeping your treats fresh to making sure they look appealing on the shelf, let’s dive into packaging machines.

Vacuum Packaging Machines

These are the superheroes of snack packaging. Vacuum packaging sucks out all the air from the package, making sure your snacks don’t meet their arch-nemesis: moisture and oxygen. This method is perfect for nuts, cheese cubes, and even meat snacks in protein packs, ensuring they stay fresh longer.

Biscuit Packaging Machines

Biscuits, cookies, or crackers – no matter what you call them, they need to stay crunchy. Biscuit packaging machines are designed to handle these delicate snacks with care, wrapping them in a cozy layer of protection that keeps the crunch inside and the moisture outside.

Bundling Equipment

Think of bundling equipment as the gatherer of snack packs. It’s perfect for creating multi-packs of smaller snack items, making it easier for consumers to carry and stores to stock. This equipment can bundle your snack packs in plastic or cardboard, ready for the shelves.

Bagging Machines

Bagging machines are the workhorses of snack packaging. Whether it’s chips, popcorn, or mixed nuts, these machines can fill, weigh, and seal bags at lightning speeds. They’re versatile too, handling everything from small sachets to family-size bags with ease.

Closing Machines

Once your snacks are safely in their bags or boxes, closing machines come into play. They make sure that the package is sealed tight, keeping the freshness in and contaminants out. These machines can work with a variety of seals, from simple stitches to heat seals.

Capping Machines

For snacks that come in jars or bottles, like gourmet nuts or specialty spreads, capping machines are essential. They precisely apply caps, ensuring that the product is secure and the shelf life is maximized. It’s the final touch in packaging that makes a big difference.

Accumulation Machinery

Last but not least, accumulation machinery. These machines collect and organize packaged snacks, making them ready for the next step in the distribution process. It’s all about efficiency, ensuring that your snacks move smoothly from packaging to pallet without any hiccups.

By selecting the right snack food packaging equipment, you’re not just keeping your snacks fresh; you’re also making them stand out on the shelf. From vacuum packaging that locks in freshness to bundling equipment that makes your snacks irresistible to buyers, each machine plays a crucial role in the journey of a snack from production to consumption. With the right tools, your snacks will not only taste great but will also look appealing, stay fresh longer, and be ready to compete in the bustling snack market.

As we continue to explore snack food packaging, the ultimate goal is to find solutions that meet your specific needs, whether it’s extending shelf life, enhancing appeal, or improving efficiency.

How to Package Snacks Efficiently

When it comes to packaging snacks efficiently, it’s all about choosing the right materials and methods to ensure your products not only catch the eye but also stay fresh from the shelf to the snack bowl. Let’s dive into some of the most effective packaging options available.

Plastic Pouch Bags

Plastic pouch bags are a favorite in the snack world for good reason. They are lightweight, flexible, and can be easily sealed to lock in freshness. Plus, they’re perfect for on-the-go snacking. When selecting a packaging machine for these bags, consider ones that offer easy changeovers between sizes and styles to accommodate a range of products, from nuts to chips.

Nitrogen Filling

To keep snacks like chips crispy and fresh, nitrogen filling is key. This process displaces oxygen in the bag, reducing the likelihood of spoilage and extending shelf life significantly. Look for snack food packaging equipment that incorporates nitrogen flushing as a feature. This not only maintains product quality but also helps in cushioning delicate snacks against damage during transport.

Cardboard Boxes

For snacks that need a bit more protection or a larger packaging format, cardboard boxes are the go-to. They offer excellent structural integrity for shipping and can be easily customized with vibrant graphics and information. Equipment that can efficiently erect, fill, and seal these boxes while maintaining high throughput rates is essential for any snack food operation looking to leverage this packaging type.

Jars

Jars, whether glass or plastic, present a premium packaging option for a variety of snacks. They’re especially popular for gourmet or artisanal products. Packaging equipment for jars should be able to handle precise filling, capping, and labeling operations to ensure a tight seal and an attractive presentation on store shelves.

Cans

Cans are not just for beverages; they’re also a fantastic option for certain types of snack foods. They offer excellent barrier protection against air and light, ensuring the contents stay fresh for longer. The right canning equipment will be able to seamlessly integrate with your existing packaging line, providing fast and reliable sealing and labeling capabilities.

It’s clear that the choice of packaging can make a significant difference in the appeal and shelf life of your snack products. By selecting the appropriate snack food packaging equipment for plastic pouch bags, nitrogen filling, cardboard boxes, jars, or cans, you can ensure your snacks not only look appealing but stay fresh longer, ready to compete in the bustling snack market.

Keep in mind that the efficiency of your packaging process directly impacts the overall quality and consumer satisfaction of your snack products. Choosing the right equipment is just the first step in building a successful snack packaging operation.

Tools and Equipment for Effective Packaging

When it comes to snack food packaging, having the right tools and equipment is as crucial as the packaging machine itself. These tools ensure the packaging process is smooth, secure, and efficient. Let’s dive into some essential tools and equipment you’ll need.

Safety Cutters: Safety comes first. When opening packages or cutting through materials during the packaging process, safety cutters are indispensable. They are designed to prevent accidents, ensuring workers are safe while maintaining productivity.

Tape Dispensers: Time is of the essence in packaging. Tape dispensers speed up the process of sealing boxes and packages, ensuring a consistent application every time. They come in various sizes and types, including hand-held and table-top models, to suit different packaging needs.

Gummed Tape: For securing packages, gummed tape offers a strong, reliable bond. When moistened, it becomes sticky and adheres well to cardboard, making it ideal for sealing boxes that will be stored or shipped. It’s an eco-friendly option, as it’s paper-based and recyclable.

Glue Guns: For quick fixes and securing items within packages, glue guns are a go-to. They provide a strong bond and are versatile enough to be used on a range of materials, making them perfect for assembling display packaging or adding extra security to packages.

Carton Staplers: For heavy-duty packaging needs, carton staplers are essential. They provide a durable way to seal boxes, ensuring they stay closed during shipping and handling. Manual and pneumatic models are available to suit different volumes and frequencies of packaging.

Heat Sealers: To ensure bags are airtight and waterproof, heat sealers are necessary. They are used to seal plastic pouch bags, creating a secure closure that protects the snacks from moisture and contaminants. This is especially important for maintaining freshness and extending shelf life.

Each of these tools plays a vital role in the packaging process, contributing to the efficiency, safety, and reliability of your snack food packaging operation. By investing in high-quality tools and equipment, you’re not just streamlining your packaging process; you’re also ensuring that your snack products are presented in the best possible way to your consumers.

As we explore further into snack food packaging, the right equipment can make all the difference in meeting consumer expectations and achieving success in the competitive snack market.

Flexible Packaging Solutions

In the snack industry, flexibility is key—not just in the types of snacks offered, but in how they’re packaged. Let’s dive into why flexible packaging solutions are becoming the go-to choice for snack food producers and how they can benefit your business.

Lightweight Packaging

Imagine you’re carrying a bag of snacks. Would you prefer it to be heavy and cumbersome or light and easy to carry? The answer is pretty straightforward. Lightweight packaging not only makes it easier for consumers to carry their favorite snacks around but also reduces shipping costs significantly. It’s a win-win.

Protective Packaging

Nobody likes opening a bag of chips to find them crushed into crumbs. That’s where protective packaging comes into play. By choosing the right snack food packaging equipment, you can ensure your snacks are shielded from the rough and tumble of transportation, keeping them fresh and intact. This not only preserves the quality of your product but also your brand’s reputation.

Customizable Options

One size doesn’t fit all, especially when it comes to snacks. Whether it’s a small bag of nuts or a large pouch of trail mix, having the ability to customize your packaging size and design is crucial. Flexible packaging solutions offer this versatility, allowing you to tailor your packaging to meet the specific needs of your product and target market. Plus, with the option to add features like zip locks or special seals, you can enhance the consumer experience even further.

Consumer-friendly Features

Speaking of enhancing the consumer experience, let’s not forget about the importance of convenience. Easy-open tabs, resealable closures, and clear windows to see the product inside are just a few features that can make your snack packaging more user-friendly. These small additions can have a big impact on consumer satisfaction and loyalty.

Lower Production Costs

Last but certainly not least, flexible packaging solutions can lead to lower production costs. They typically require less material than traditional packaging options and can be produced at a faster rate. This efficiency not only helps keep your costs down but also allows you to respond more quickly to market demands.

As we move on to addressing some of the most frequently asked questions about snack food packaging equipment, keep in mind that choosing flexible packaging solutions can significantly enhance your product’s appeal, protect its integrity, and contribute to your bottom line.

Frequently Asked Questions about Snack Food Packaging Equipment

When navigating snack food packaging, several questions frequently come up. Let’s dive into some of the most common inquiries to shed light on the best practices, materials, and trends in the industry.

What are the best materials for snack food packaging?

The ideal materials for snack food packaging strike a balance between protecting the product and meeting consumer demands for sustainability. Here are some top picks:

- Flexible Packaging: Materials like polyethylene (PE), polypropylene (PP), and polyester (PET) offer excellent moisture and oxygen barriers, essential for keeping snacks fresh.

- Recyclable Plastics: With an increasing focus on environmental responsibility, recyclable plastics are becoming more popular.

- Biodegradable Options: Materials like PLA (polylactic acid) derived from cornstarch are gaining traction for their lower environmental impact.

How can packaging equipment improve snack food shelf life?

Packaging equipment plays a pivotal role in extending the shelf life of snack foods by ensuring airtight seals and incorporating preservation techniques. Here’s how:

- Nitrogen Flushing: Machines that fill bags with nitrogen instead of air help prevent oxidation, keeping snacks crisp and fresh longer.

- Vacuum Packaging: Removing air from packages minimizes the risk of microbial growth and spoilage.

- Sealing Integrity: Equipment that ensures robust, leak-proof seals prevents moisture and contaminants from compromising the product’s quality.

What are the latest trends in snack food packaging?

Keeping up with trends is crucial for staying competitive in the snack food market. Here are some current movements:

- Sustainability: There’s a strong push towards more sustainable packaging solutions, including recyclable and compostable materials.

- Smart Packaging: Innovations like QR codes and NFC tags offer consumers additional product information, enhancing engagement and trust.

- Convenience Features: Easy-open, resealable packages and single-serving sizes cater to consumers’ on-the-go lifestyles.

Selecting the right snack food packaging equipment involves considering your product’s specific needs, consumer preferences, and the latest industry innovations. By staying informed and adaptable, you can choose solutions that will keep your snacks fresh, appealing, and competitive in the bustling market.

Conclusion

In wrapping up our journey through snack food packaging, it’s crucial to highlight the significance of choosing the right equipment. Not only does it ensure your snacks remain fresh and appealing, but it also plays a pivotal role in staying competitive in this bustling market. At CFAB Global, we understand these needs deeply. That’s why we’ve developed a comprehensive Machine Reliability Program that stands as a testament to our commitment to excellence in snack food packaging equipment.

Our Machine Reliability Program is designed to ensure that your packaging operations run smoothly, efficiently, and without unexpected downtime. We believe that reliability in your equipment is not just about the machinery itself but about the ongoing support and maintenance that keeps it in top condition. This program encompasses regular check-ups, updates, and immediate access to technical support, ensuring that any potential issues are addressed before they can impact your production line.

At CFAB Global, our focus is not just on selling you a machine; it’s about providing a solution that integrates seamlessly into your operation, enhancing productivity, and ultimately, your bottom line. Our snack food packaging equipment is designed with your needs in mind, offering flexibility, efficiency, and the highest standards of hygiene. Whether you’re packaging chips, nuts, granola bars, or any other snack, our machines are built to handle your specific requirements, ensuring that your products reach the consumer in the best possible condition.

In the snack food industry, packaging is as important as the product itself. It’s not just about preserving freshness; it’s about capturing consumer attention, conveying quality, and providing convenience. With CFAB Global’s snack food packaging equipment, backed by our Machine Reliability Program, you can achieve all these goals and more. Let us help you take your snack packaging to the next level, ensuring that your products stand out on the shelves and in the minds of consumers.

In conclusion, selecting the right packaging solution is a critical decision for any snack food producer. By partnering with CFAB Global, you’re choosing a partner dedicated to innovation, reliability, and customer success. Explore our range of snack food packaging solutions today, and let’s work together to create packaging that not only preserves your product but also enhances its appeal to consumers.