Contact Us

For Any

Solution

Call Anytime

+1-855-490-2322

VibraFloor - Introduction

Over the last 30 years, VibraFloor has delivered an innovative modular vibrating reclaim system to over 250 sites worldwide, ensuring complete emptying of bulk products from steel and concrete silos, hoppers, warehouses, railcars, and ships.

CFAB Global, the only authorized representative and partner of VibraFloor in the United States, offers this advanced technology, which utilizes low-power vibrating motors to generate waves on flexible surface plates. These waves undermine and collapse the leading edge of cohesive and free-flowing bulk products, creating a progressive avalanche, much like the natural erosion of a cliff by the ocean. This allows for easy reclamation of stored materials.

VibraFloor’s system is versatile and effective across a wide range of industries and products, including:

- Biomass Silos: Wood Pellets, Wood Chips, Sawdust, Bagasse, Husk

- Animal Feed Silos: Soybean Meal, DDGS, Canola Meal, Feed Pellets

- Food and Agricultural Silos: Raw or Refined Sugar, Flour, Bran

- Cereal Silos: Wheat, Barley, Malt, Maize, Soybean, Canola

- Industrial Silos: Cement, Fly Ash, Potash, RDF, Fertilizer

Within any project, VibraFloor can be adapted to meet the needs of ground reception hoppers, process feed hoppers, or bulk storage silos up to 63 meters in diameter, making it an optimal solution across various applications.

No other reclaim system offers the same balance of advantages, which include:

- No routine maintenance aside from visual inspection

- No damaging vibration or stress transfer to the silo or structure

- Effective reclaiming of cohesive and free-flowing bulk products

- Very low energy consumption

- High potential reclaim rates

- Gentle action that preserves product integrity (e.g., rice kernels, wood pellets, fertilizer crystals)

- Adaptability to any silo size or shape

- No rotating or wearing parts (other than the motor)

- Installation in new silos or retrofitting in existing flat-bottom silos

We are also proud to include ISO 9001 certification among VibraFloor’s many accreditations, ensuring quality and reliability in every system.

VibraFloor - A Revolutionary Reclaim System

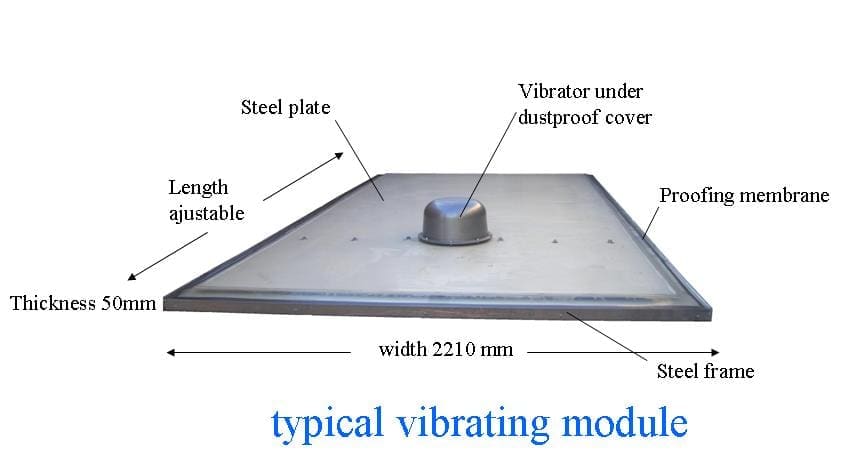

The Vibrafloor concept stands out as a distinctive reclaim solution for silos and various bulk storage containers, offered by CFAB Global. Diverging from the conventional reclaim systems that rely on high energy consumption and heavy-duty machinery, the VibraFloor approach showcases the efficiency and capability of numerous low-power modules working in tandem. This innovative system ensures the thorough emptying of bulk storages, regardless of their size or shape, marking a significant advancement in storage technology.

The VibraFloor system, presented by CFAB Global, revolutionizes the way bulk storage and silos are emptied. Utilizing a combination of aeration and gravitational assistance, the product is moved forward on the plate by a wave motion, facilitated by the floor’s slight incline, until the material is fully cleared from a module. This process is meticulously monitored by sensors that activate adjacent modules or zones in a sequential manner, ensuring a smooth and complete emptying of the storage facility.

This entire operation is automated, managed by a dedicated Programmable Logic Controller (PLC) that springs into action upon receiving a demand signal. Safety is at the core of the VibraFloor concept, eliminating the need for human entry into potentially hazardous environments. The system is designed to ensure complete product removal without manual intervention, significantly reducing risks to personnel.

In the rare case of a motor or sensor malfunction, the modular design of VibraFloor allows for the continuation of the emptying process by neighboring modules, minimizing the leftover residue. Moreover, the unique wave action, while powerful, does not compromise the structural integrity of the storage facility, thanks to the strategic use of springs and flexible membranes that isolate the wave energy.

VibraFloor embodies a safe, efficient, and innovative solution for emptying silos and bulk storage, prioritizing both the safety of personnel and the preservation of the storage structure.

This wave motion creates a low-pressure zone that weakens and causes the leading edge of both cohesive and free-flowing materials to collapse, resulting in a progressive cascade of the stored contents, akin to the process of cliff erosion.