Contact Us

For Any

Solution

Call Anytime

+1-855-490-2322

BE Machinery - Packaging Systems

These machines are engineered to meet the highest standards of hygiene, making them ideal for producing goods with extended shelf life. Built for performance and efficiency, these systems are capable of handling a wide range of production demands, with output speeds ranging from 1,000 to 12,000 containers per hour, depending on the product type and requirements.

At the heart of this advanced technology is a servo-driven CNC filling machine, meticulously designed to ensure precision and control throughout the entire process. All machine functions are fully servo or pneumatically driven, providing seamless operation and exceptional reliability. The system is controlled through an intuitive interface, allowing operators to manage and adjust settings directly from the control panel. This flexibility and automation translate to an impressive output speed of up to 6,000 containers per hour, making it an ideal solution for high-volume production environments.

With these machines, businesses can achieve consistent product quality, increased production efficiency, and superior control over their manufacturing processes—all while maintaining strict hygienic conditions and ensuring that products retain their freshness and integrity for extended periods. Whether in the food, pharmaceutical, or chemical industries, these filling machines offer the ideal combination of speed, precision, and cleanliness to meet the most demanding operational needs.

Machines

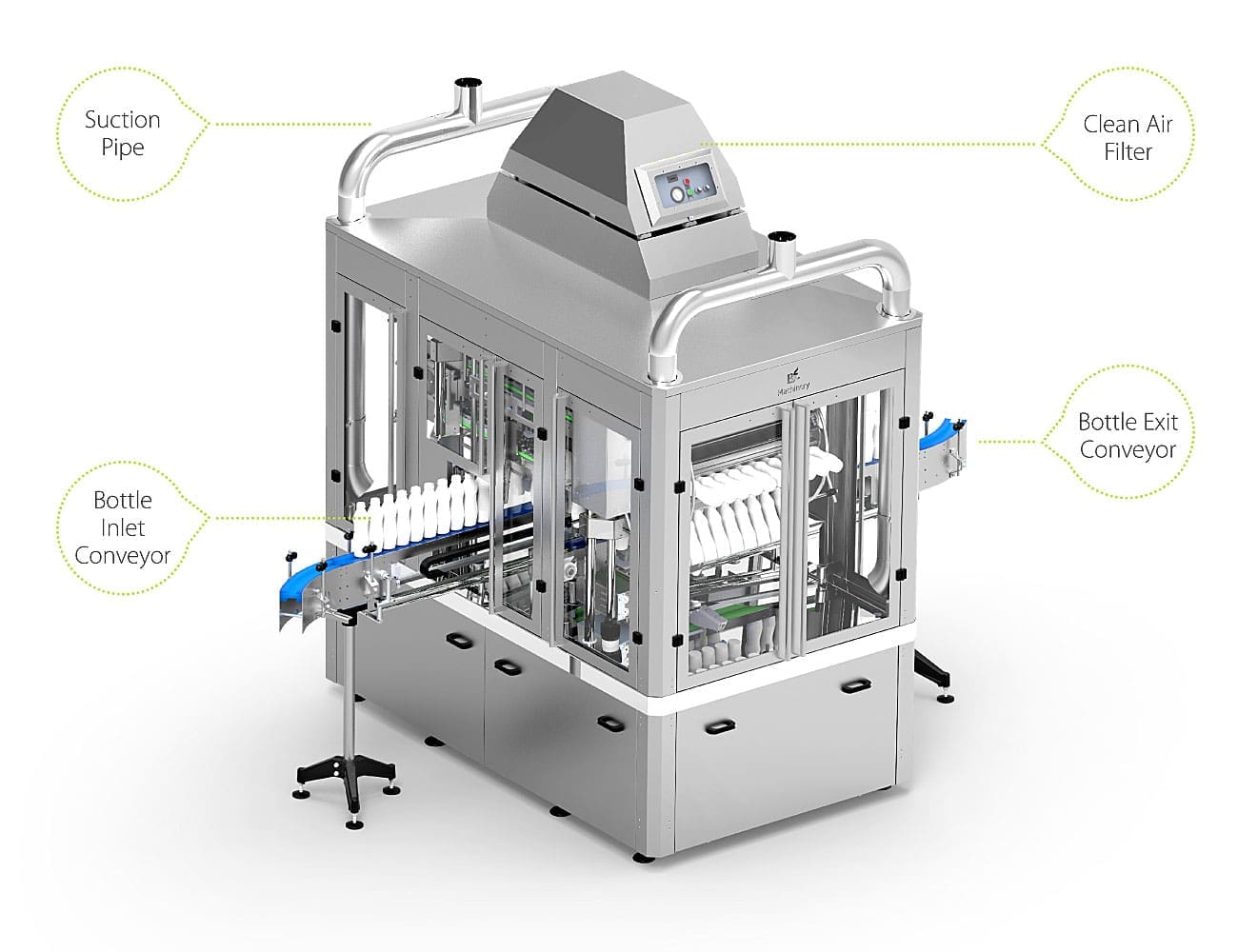

The High-Clean Continuous Bottle Cleaner (AWC Series)

The AWC series High-Clean Continuous Bottle Cleaner is engineered to deliver exceptional flexibility and performance, making it an indispensable solution for a wide range of industries. These machines are designed to handle containers of various sizes, shapes, and materials, offering a versatile setup that can easily adapt to changing production needs.

One of the standout features of the AWC series is its ability to maintain high levels of cleanliness and hygiene, critical for industries like food and beverage, pharmaceuticals, and cosmetics. This ensures that each container is thoroughly cleaned and ready for filling, meeting stringent hygiene standards to safeguard product quality and consumer safety.

The system is capable of processing up to 15,000 containers per hour, making it an ideal choice for high-volume production lines. Whether you are handling small, uniquely shaped containers or larger, more conventional ones, the AWC series is designed to handle it all with ease. Its robust yet adaptable configuration allows for seamless integration into existing production lines, reducing downtime and maximizing operational efficiency.

Incorporating advanced technology, these machines offer a range of capabilities, from gentle cleaning for sensitive materials to more rigorous cleaning for industrial applications. Operators can easily adjust settings through an intuitive control interface, ensuring optimal performance and customization based on production demands.

Whether you’re working in the food, beverage, pharmaceutical, or chemical sectors, the High-Clean Continuous Bottle Cleaner from the AWC series delivers both speed and flexibility without compromising on quality or cleanliness. This makes it an ideal solution for businesses looking to enhance their production efficiency while maintaining the highest standards of hygiene and product integrity.

The AFR Series High-Clean Filling Machines

The AFR series High-Clean Filling machines are meticulously engineered to meet the most stringent hygienic standards, making them ideal for industries that prioritize sanitation and product quality. These machines are designed to fill products with extended shelf-life requirements, ensuring that each container is processed in a contaminant-free environment that adheres to the highest levels of cleanliness.

Built for versatility and efficiency, the AFR series offers impressive output speeds, with the ability to fill up to 3,600 containers per hour. This makes them perfect for operations demanding consistent, high-volume production without compromising the quality of the product. Whether filling liquid, semi-liquid, or viscous products, these machines ensure precise, reliable performance with every batch.

The inline filling system of the AFR series is designed to integrate seamlessly into your production line, providing flexibility for a variety of container sizes and shapes. The machines are equipped with advanced automation controls, allowing for easy adjustment of filling parameters through a user-friendly interface. This ensures that your production line can maintain high levels of efficiency while minimizing downtime and operator intervention.

Additionally, the AFR series filling machines are constructed with materials that are resistant to wear and contamination, further enhancing their hygienic performance. The system’s fully enclosed design minimizes the risk of external contaminants, while the precision filling technology ensures that each container is filled with accuracy, reducing product waste and improving overall production efficiency.

Whether you’re in the food, beverage, pharmaceutical, or cosmetics industry, the AFR series High-Clean Filling machines deliver a reliable solution that helps extend product shelf life, maximize output, and maintain superior hygiene throughout the production process. This combination of speed, precision, and cleanliness makes the AFR series an essential asset for businesses looking to optimize their filling operations while ensuring product safety and quality.