Self evacuating oil drain systems are changing how businesses manage oil changes, offering a smoother, more efficient process to ensure operational efficiency. With these innovative tools, oil changes become less frequent interruptions and more a seamless part of machinery maintenance.

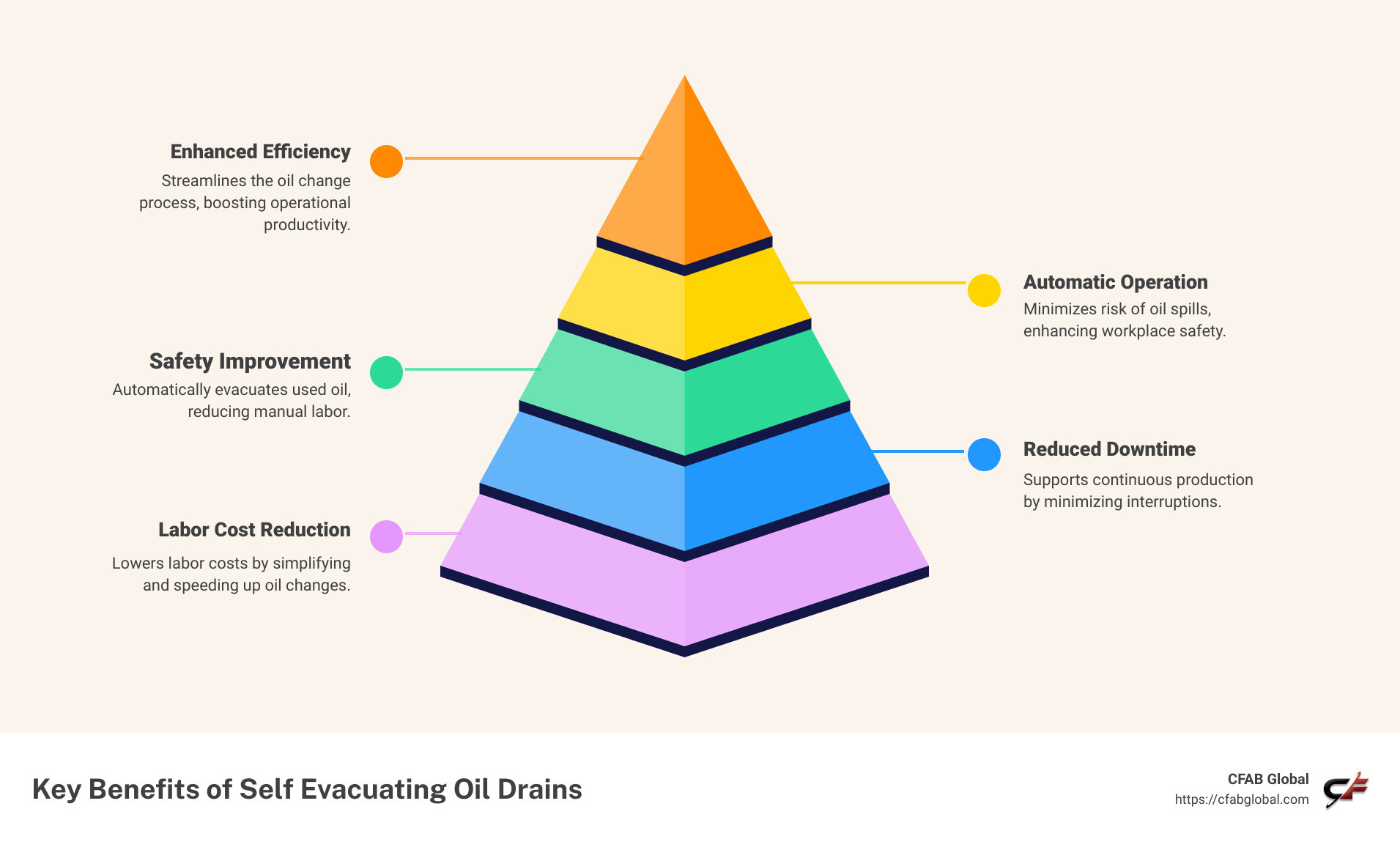

Key benefits of a self evacuating oil drain:

- Simplifies oil changes, reducing labor time

- Automatically evacuates used oil without manual intervention

- Improves workplace safety by minimizing oil spill risks

- Reduces downtime, supporting continuous production

I’m Todd Cleppe, CEO & Co-Founder of CFAB Global. With over 25 years in designing machinery solutions, I’ve worked extensively on enhancing systems like the self evacuating oil drain to boost operational output and extend equipment life. This topic dives deeper into how these systems can impact your business’s efficiency.

Basic self evacuating oil drain terms:

– air powered oil extractor

– electric oil evacuation pump

– manual fluid extractor and dispenser

Understanding Self Evacuating Oil Drains

Self evacuating oil drains are a game-changer for anyone tired of the messy, time-consuming process of traditional oil changes. These systems make the task quicker and cleaner, enhancing safety and efficiency in any workshop.

Key Features

One standout feature is the auto-check technology. This user-friendly innovation eliminates the need to manually close a ball valve before evacuation. Instead, the system automatically seals when air pressure is applied. This means fewer spills and a much smoother operation.

Another critical component is the pressure relief safety valve. This valve ensures that the drain doesn’t over-pressurize, adding an essential layer of safety. It’s a simple yet effective way to prevent accidents and keep the workspace secure.

The construction of these drains often includes durable materials like polyethylene. This choice of material offers excellent resistance to chemicals and oil, ensuring a long life for the equipment. It also keeps the system lightweight and easy to handle.

Benefits of Self Evacuating Oil Drains

The design of these oil drains focuses on easy maneuverability. With features like chemical-resistant casters, moving the drain around the workshop is a breeze. These casters are built to withstand harsh chemicals and oils, ensuring that the drain remains stable and mobile even in challenging conditions.

Moreover, the stability and mobility provided by a four-caster design cannot be overstated. This setup ensures that the drain can be easily positioned under vehicles without tipping over, making the oil change process even more efficient.

In conclusion, self evacuating oil drains offer several advantages that make them a valuable addition to any maintenance operation. They simplify oil changes, improve safety, and improve overall efficiency. Let’s explore how these systems function in more detail.

How Self Evacuating Oil Drains Work

Auto-Check Technology Explained

The magic behind self evacuating oil drains lies in their efficient and user-friendly design. At the heart of this innovation is the auto-check technology, which streamlines the drain evacuation process.

Drain Evacuation Process and Auto-Check Technology

Imagine you’re in a busy workshop and need to change oil quickly. Traditional oil drains require manual sealing, which can lead to messy spills if not done correctly. With auto-check technology, this step is automated. As soon as air pressure is applied, the system automatically seals itself. This feature not only saves time but also reduces the risk of oil spills, keeping your workspace clean.

Air Pressure Regulation

Regulating air pressure is crucial for the proper functioning of these drains. When you apply air pressure, it triggers the auto-check mechanism, ensuring the drain is sealed for evacuation. This makes the oil change process smooth and efficient, eliminating the need for manual intervention.

Sight Glass: A User-Friendly Feature

Another handy feature is the sight glass. This transparent tube allows you to monitor the oil level inside the tank. It’s a simple yet effective way to ensure that the tank doesn’t overfill during the evacuation process. By keeping an eye on the sight glass, you can prevent potential overflow and maintain a clean environment.

Automatic Sealing and Safety

The automatic sealing mechanism is not just about convenience; it’s also about safety. It ensures that the oil is securely contained during the evacuation process, reducing the risk of leaks. This feature, combined with the pressure relief valve, provides a double layer of protection, making the system both safe and reliable.

In summary, auto-check technology and features like the sight glass transform the oil change experience, making it faster, cleaner, and safer. This innovation is a testament to how technology can simplify everyday tasks in the workshop. We’ll explore how to choose the right self evacuating oil drain for your needs.

Choosing the Right Self Evacuating Oil Drain

Comparing Models

When it comes to selecting the perfect self evacuating oil drain, understanding the differences between models is crucial. Two popular options are the JDI-18DC and the JDI-27DC. Each offers unique features custom to different needs.

Capacity Options

The first thing to consider is capacity. The JDI-18DC boasts an 18-gallon steel tank, making it ideal for smaller shops or those with moderate oil change needs. On the other hand, the JDI-27DC offers a larger capacity, perfect for busier environments where frequent oil changes occur. Choosing the right capacity ensures efficiency and minimizes the need for frequent emptying.

Material Differences

Material construction is another important factor. The JDI-18DC is crafted from durable steel, providing robustness and longevity. Steel is resistant to wear and tear, making it a reliable choice for those who prioritize durability. While the specifics of the JDI-27DC’s material aren’t detailed here, typically, larger models also emphasize durability and resistance to damage.

Height Adjustment

Height adjustment is a feature that improves usability. The JDI-18DC offers a height range from 36-1/2” to 59”. This flexibility allows you to position the drain comfortably under various vehicles, ensuring efficient oil collection without the need for additional adjustments or tools. It’s perfect for workshops with diverse vehicle types.

Key Specifications

Let’s break down the specifications for a clearer comparison:

| Feature | JDI-18DC | JDI-27DC |

|---|---|---|

| Capacity | 18 gallons | Larger than 18 gallons |

| Material | Steel | Durable materials |

| Height Adjustment | 36-1/2” to 59” | Adjustable |

| Funnel Size | 16” diameter | Larger funnel |

| Weight | 42 lbs | Heavier for stability |

These specifications highlight the strengths of each model, helping you make an informed decision based on your specific workshop needs. Whether you prioritize capacity, material durability, or flexibility in height, understanding these elements ensures you choose the right tool for efficient and safe oil changes.

For those looking for advanced oil evacuation solutions, consider exploring Graco Inc. solutions for reliable and efficient equipment tailored to your needs.

Frequently Asked Questions about Self Evacuating Oil Drains

What is a self evacuating oil drain?

A self evacuating oil drain is a tool designed to make oil changes more efficient and less messy. It collects used oil from vehicles and automatically evacuates it, typically using air pressure, into a storage container. This eliminates the need for manual draining, saving time and reducing the risk of spills. These drains are especially useful in busy workshops where time and cleanliness are crucial.

How does auto-check technology work?

Auto-check technology simplifies the oil evacuation process. When air pressure is applied, this technology automatically seals the drain, allowing for easy and clean oil evacuation. This means you don’t have to manually close a valve, reducing the chance of operator error and oil spills. It’s a user-friendly feature that improves the overall efficiency of oil changes, making the process both quicker and cleaner.

What are the safety features of these drains?

Safety is a top priority with self evacuating oil drains. Here are some key safety features:

-

Pressure Relief Safety Valve: This valve prevents the tank from over-pressurizing, ensuring safe operation during evacuation.

-

Chemical-Resistant Casters: The drains are equipped with casters that resist oil and chemicals, ensuring stability and mobility even in demanding workshop environments.

-

OSHA-Friendly Labeling: Proper labeling provides clear instructions and warnings, promoting safe usage by all operators.

These features work together to ensure that using a self evacuating oil drain is not only efficient but also safe for both the operator and the environment.

Conclusion

At CFAB Global, we understand the importance of operational efficiency in today’s industries. Our Machine Reliability Program is designed to improve the performance and lifespan of your machinery, ensuring that your operations run smoothly and efficiently. With our expertise and custom solutions, we help businesses like yours reduce downtime and maximize productivity.

Self evacuating oil drains play a crucial role in maintaining this efficiency. By simplifying the oil change process, these innovative tools save time and reduce the risk of spills, allowing your team to focus on what they do best. With features like auto-check technology and pressure relief safety valves, they offer a user-friendly and safe solution for busy workshops.

Choosing the right equipment is vital to achieving operational success. At CFAB Global, we provide personalized analysis and support to help you select the best tools for your needs. Whether it’s a self evacuating oil drain or other machinery solutions, our commitment is to ensure your equipment operates at peak performance.

For more information on how our services can benefit your business, visit our Graco solutions page and find how CFAB Global can transform your operations.