Sauce filling machine suppliers play a crucial role in the food packaging industry, ensuring that sauce products are bottled efficiently and meet high quality standards. When selecting the right supplier, you should look for:

- Efficient and reliable machinery

- Versatility to handle different viscosities and bottle sizes

- Customization options to suit your production needs

Modern sauce filling machines cater to a myriad of sauce types, from the thinnest vinaigrettes to the thickest barbecue sauces. These machines ensure that the bottling process is not only seamless but also maintains the hygiene and consistency of your products. An effective filling machine can significantly improve production efficiency, reduce waste, and maintain the desired product quality.

At CFAB Global, I’ve had the opportunity to witness the innovations in sauce filling machinery. In my role, I have worked with top manufacturers to integrate solutions that improve efficiency and meet diverse client needs. As we dig deeper into the intricacies of sauce filling machines, you’ll find what makes a supplier truly stand out in this competitive market.

Quick look at sauce filling machine suppliers:

– commercial sauce making equipment

– commercial sauce mixer

– hot sauce manufacturing equipment

Understanding Sauce Filling Machines

Sauce filling machines are essential in the food industry, especially for producers aiming to maintain quality and efficiency in packaging. These machines come in various forms, each designed to handle specific tasks and sauce types. Let’s explore the key types of sauce filling machines.

Automatic Sauce Filling

Automatic sauce filling machines are a game-changer for high-volume production environments. These machines can fill thousands of bottles per hour with minimal human intervention. They use advanced technologies like PLC control systems to ensure precise and consistent filling. This automation not only speeds up the production process but also reduces human error, making it ideal for large-scale operations. For those looking to enhance their food packaging solutions, consider exploring BE Machinery’s packaging solutions.

Semi-Automatic Filling

For smaller operations or those seeking flexibility, semi-automatic filling machines offer a practical solution. These machines require some manual input but still provide a significant boost in efficiency compared to manual filling. They are perfect for businesses that produce a variety of sauce types and need to switch between different products quickly. With semi-automatic machines, you get a balance of control and automation.

High Viscosity Piston Filler

When dealing with thick sauces like mayonnaise or peanut butter, a high viscosity piston filler is your best bet. This type of machine uses a piston and cylinder mechanism to handle dense liquids effectively. The piston draws the sauce into the cylinder and then dispenses it into containers with precision. This method ensures that even the thickest sauces are filled without clogs or inconsistencies. For more advanced food processing solutions, BE Machinery’s process systems offer a range of options.

Each of these machines plays a vital role in the sauce production line, ensuring that products are filled accurately and efficiently. Whether you’re a small business or a large manufacturer, understanding these machines can help you make informed decisions to improve your production capabilities.

Top Sauce Filling Machine Suppliers

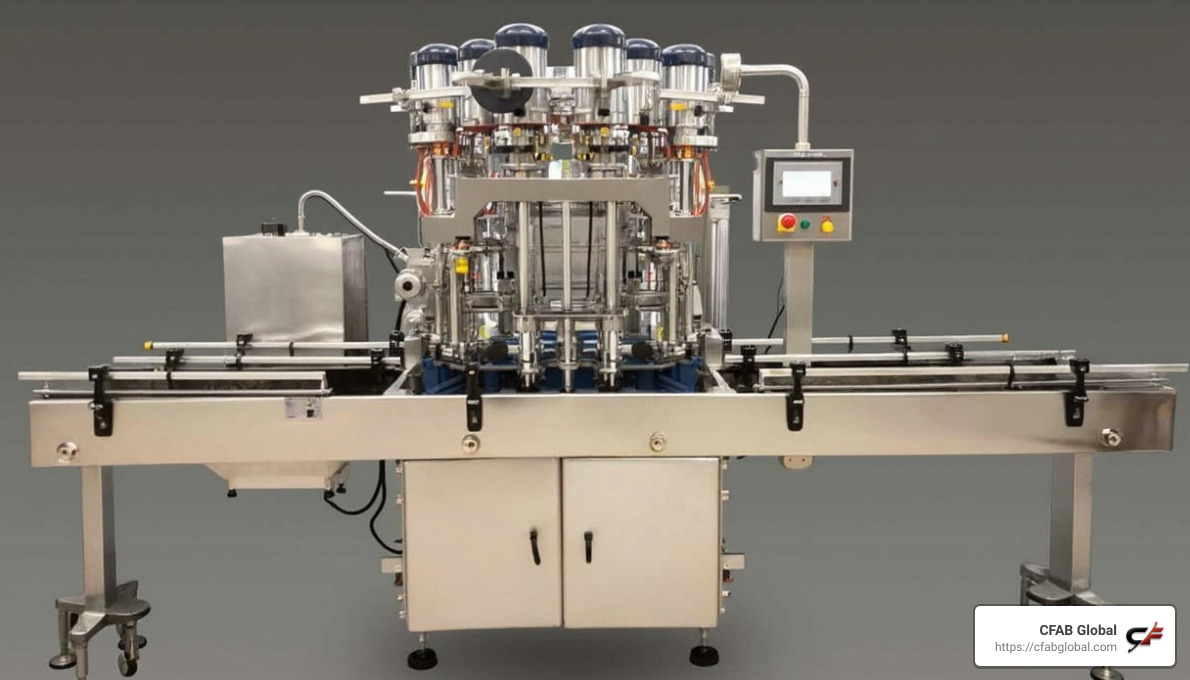

When it comes to sauce filling machine suppliers, CFAB Global stands out as a leader in the industry. Known for their commitment to quality and innovation, CFAB Global offers a range of filling machines custom to meet the diverse needs of sauce manufacturers.

CFAB Global

CFAB Global has established itself as a reliable partner for businesses in the food industry. They offer a comprehensive selection of sauce filling machines designed to handle everything from thin vinaigrettes to thick barbecue sauces. These machines are built with high-quality materials, like stainless steel, ensuring durability and hygiene.

One of the key features of CFAB Global’s offerings is their use of PLC control systems. This technology allows for precise control over the filling process, reducing waste and ensuring consistency. Whether you need an automatic or semi-automatic solution, CFAB Global has machines that can be customized to fit your production needs.

Their customer service is another area where CFAB Global excels. They provide lifetime technical support and have engineers available to service machines overseas. This level of support ensures that your production line runs smoothly, minimizing downtime and maximizing efficiency.

In addition to sauce filling machines, CFAB Global offers a range of complementary equipment to streamline your production process. For example, they provide solutions for bottle sterilization and packaging, ensuring your products meet the highest hygiene standards. For these needs, consider BE Machinery’s bottle sterilization and packaging solutions, which are designed to integrate seamlessly with CFAB Global’s machines.

Choosing CFAB Global as your sauce filling machine supplier means investing in quality, reliability, and a partner dedicated to your success. Their machines are not just tools; they are a gateway to increased productivity and profitability for your business.

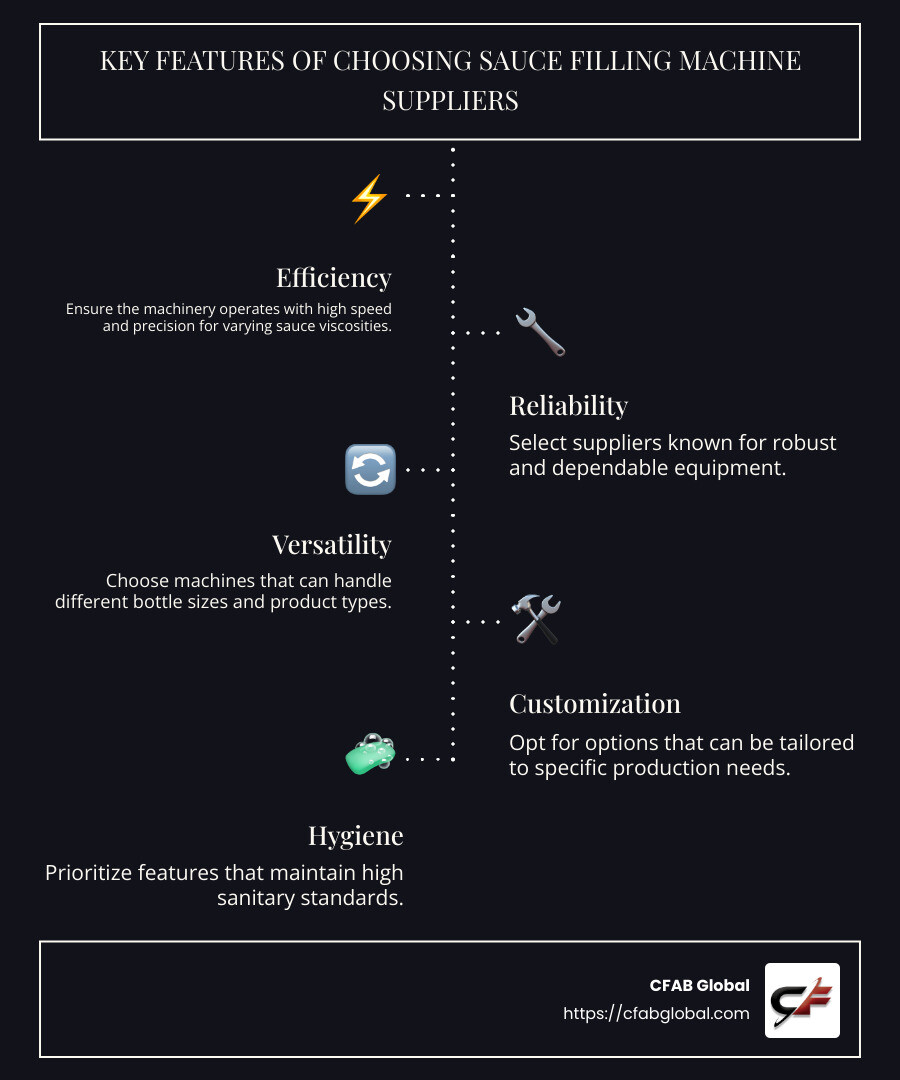

Key Features of Sauce Filling Machines

When selecting a sauce filling machine, understanding the key features can make a big difference in your production line’s efficiency and product quality. Let’s explore some of these essential features:

Stainless Steel Construction

Sauce filling machines made with stainless steel offer durability and hygiene. Stainless steel is resistant to corrosion, making it ideal for food processing environments where moisture and acidic ingredients are common. It also ensures that the machines are easy to clean and maintain, which is crucial for meeting food safety standards. This material choice aligns with industry standards, such as the USDA and 3A dairy standards, ensuring that your equipment is up to par with regulatory requirements. For top-notch food processing solutions, consider exploring BE Machinery’s offerings.

PLC Control System

A PLC (Programmable Logic Controller) control system is a game-changer for sauce filling machines. This system provides precise control over the filling process, allowing operators to adjust settings like fill volume and speed with ease. The PLC system improves accuracy and reduces waste by ensuring consistent fills every time. It also offers the flexibility to handle various types of sauces, from thin dressings to thick, chunky salsas. This capability is essential for manufacturers looking to maintain product quality and reduce operational costs.

Ergonomic Design

An ergonomic design in sauce filling machines focuses on user-friendly interfaces and ease of operation. Machines with ergonomic features often include touch screens for easy adjustments, intuitive controls, and designs that minimize operator strain. This design approach not only improves the efficiency of the production line but also improves worker satisfaction and safety. By prioritizing ergonomics, manufacturers can reduce the risk of operator fatigue and errors, leading to smoother operations and higher productivity.

Incorporating these key features into your sauce filling machine selection will ensure that your production line is efficient, reliable, and capable of producing high-quality products consistently. With advancements in technology and design, these machines are more than just tools—they are integral components of a successful manufacturing process.

Sauce Filling Machine Suppliers: What to Consider

When choosing sauce filling machine suppliers, there are several critical factors to keep in mind to ensure you make the best decision for your production line. Let’s explore the key considerations:

Production Goals

Start by defining your production goals. Understanding the volume of sauce you need to produce daily or monthly will guide your machine selection. For high-volume production, automatic machines are ideal. On the other hand, semi-automatic machines might be sufficient for smaller operations. Aligning your machine choice with your production targets helps optimize efficiency and cost-effectiveness.

Machine Reliability

Machine reliability is paramount. You want equipment that can perform consistently without frequent breakdowns. Look for machines with a reputation for durability and minimal maintenance needs. For instance, machines with stainless steel construction, like those from BE Machinery, offer robust performance and longevity. Reliable machines reduce downtime, ensuring your production line runs smoothly and continuously.

Customization Options

Every production line is unique, and customization can be a significant advantage. Consider suppliers that offer machines with customizable features to match your specific needs. Whether it’s adjustable nozzles for different bottle sizes or programmable settings for various sauce viscosities, customization ensures the machine fits seamlessly into your existing setup. Companies like BE Machinery provide options to tailor machines to your production requirements, enhancing flexibility and efficiency.

By focusing on these aspects—production goals, machine reliability, and customization options—you can select a sauce filling machine supplier that aligns with your business needs and helps drive your success.

Now, let’s address some common questions about sauce filling machine suppliers.

Frequently Asked Questions about Sauce Filling Machine Suppliers

What types of sauce filling machines are available?

When it comes to sauce filling machines, there are several types to choose from, each catering to different production needs:

-

Automatic Sauce Filling Machines: These are perfect for high-volume production and require minimal human intervention. They are programmable and can handle a variety of sauces, from thin liquids to thick pastes. Their efficiency makes them ideal for large-scale operations.

-

Semi-Automatic Sauce Filling Machines: These machines require some manual operation but offer more control over the filling process. They are suitable for medium-sized operations where flexibility and precision are important.

-

Pouch Filling Machines: Designed for filling sauces into pouches, these machines are great for companies looking to package sauces in flexible, convenient formats. They can be both automatic and semi-automatic, depending on your production scale.

How do I choose the right sauce filling machine supplier?

Selecting the right supplier is crucial for ensuring a smooth production process. Consider these factors:

-

Production Requirements: Understand your production needs. Do you need a machine that handles thousands of bottles per hour, or are you looking for something for smaller batches? Your production scale will guide your choice.

-

Customization: Look for suppliers that offer customization options. Machines that can be custom to fit your specific sauce types and packaging needs will be more beneficial in the long run.

-

Support Services: Reliable support is key. Choose suppliers that provide excellent customer service, technical support, and maintenance services to keep your machines running efficiently.

What are the benefits of using a sauce filling machine?

Investing in a sauce filling machine brings several advantages:

-

Efficiency: Machines automate the filling process, significantly increasing production speed and reducing labor costs. This efficiency is crucial for meeting high production demands.

-

Accuracy: Modern machines are designed for precise filling, ensuring consistent product volume in each container. This accuracy helps maintain product quality and brand reputation.

-

Hygiene: High-quality machines are constructed from materials like stainless steel that are easy to clean and maintain, ensuring that hygiene standards are met and reducing the risk of contamination.

By understanding these aspects, you can make informed decisions about which sauce filling machine and supplier will best meet your business needs.

Next, we’ll explore the key features that make sauce filling machines stand out.

Conclusion

In the dynamic world of sauce filling, CFAB Global stands as a leader, providing top-notch solutions custom to meet the diverse needs of businesses. Our Machine Reliability Program is at the heart of what we offer, ensuring that your operations run smoothly and efficiently.

CFAB Global is committed to helping you achieve your production goals with minimal downtime. Our expertise spans across various industries, and we take pride in delivering customized solutions that improve the performance and lifespan of your machinery.

With our Machine Reliability Program, we offer a holistic approach that includes personalized analysis, state-of-the-art services, and ongoing support. This program is not just about maintaining equipment; it’s about maximizing productivity and ensuring your machinery operates at its best.

Our industry expertise ensures that we understand the unique challenges you face. Whether you are in manufacturing, construction, agriculture, or energy, CFAB Global has the experience and solutions to help you excel.

Partnering with us means choosing a future where your machinery is reliable, efficient, and custom to your specific needs. Our commitment to your success is unwavering, and we are here to support you every step of the way.

For more information on how CFAB Global can improve your operations with our advanced machinery solutions, visit our Food Manufacturing Equipment page.