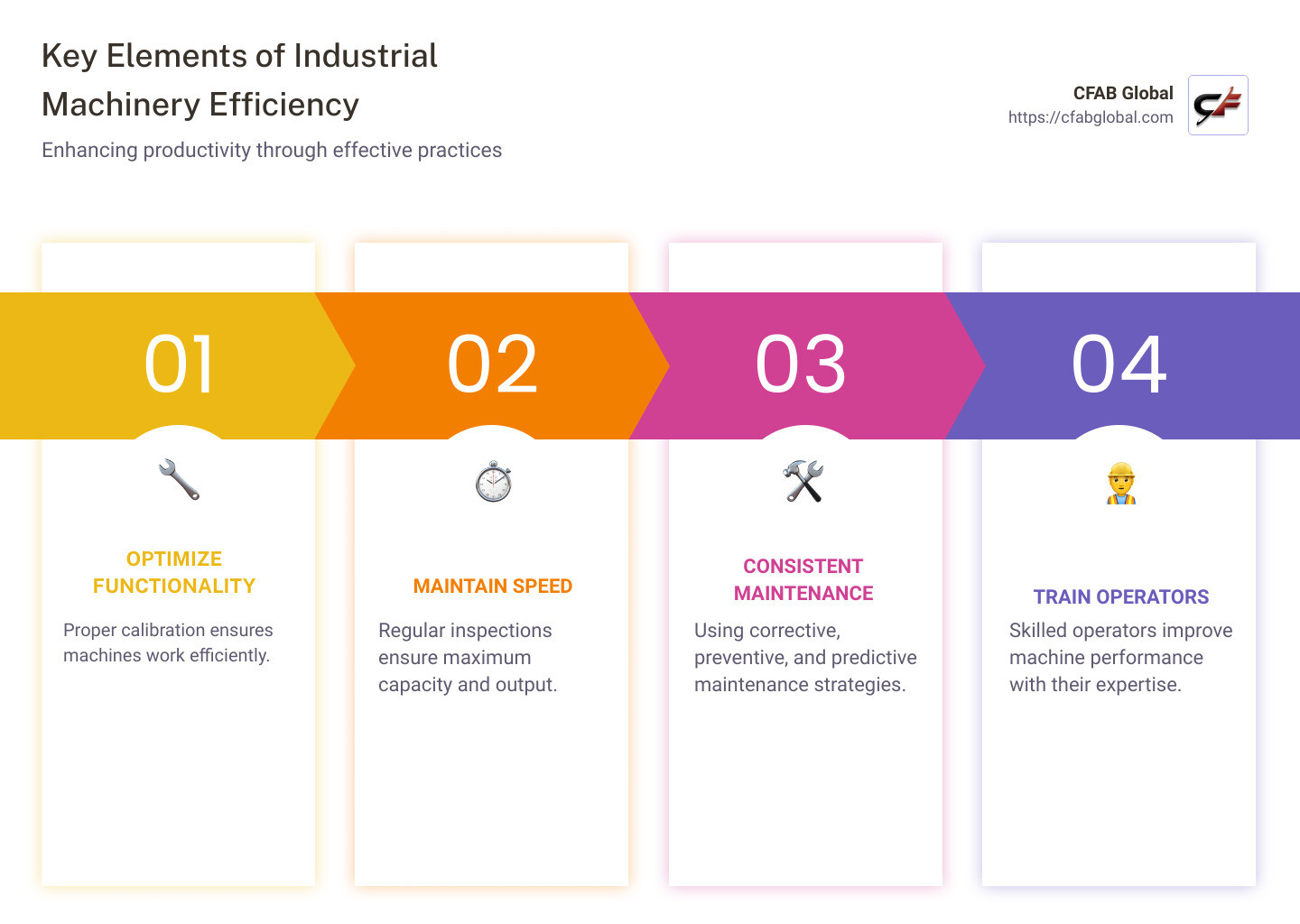

Industrial machinery efficiency is a crucial aspect that impacts the productivity and profitability of any manufacturing organization. Enhancing this efficiency involves optimizing the functionality, speed, maintenance, and operator training of industrial machinery, all of which contribute to increased production output while minimizing energy consumption. These improvements enable companies to achieve higher efficiency and reliability in their operations.

- Optimize machinery functionality: Properly calibrated machines are more efficient.

- Maintain machinery speed: Regular inspections help maintain maximum capacity.

- Implement consistent maintenance: Combining corrective, preventive, and predictive maintenance ensures machinery runs smoothly.

- Train operators effectively: Skilled operators understand machine status and perform essential tasks correctly.

For companies in sectors like manufacturing, agriculture, or energy, achieving top-notch industrial machinery efficiency can notably reduce downtime and extend machinery lifespan, directly boosting the bottom line. By leveraging advanced solutions from companies like BE Machinery, which offers superior food packaging equipment, or Graco Inc. for automated lubrication systems, firms can upgrade their setups to deal with modern challenges effectively.

My name is Todd Cleppe, and at CFAB Global, I have dedicated over 25 years to improving machinery efficiency across various industries, significantly reducing downtime and operational costs. My work has enabled numerous companies to capitalize on industrial machinery efficiency, increasing their production capabilities and achieving lasting solutions.

Understanding Industrial Machinery Efficiency

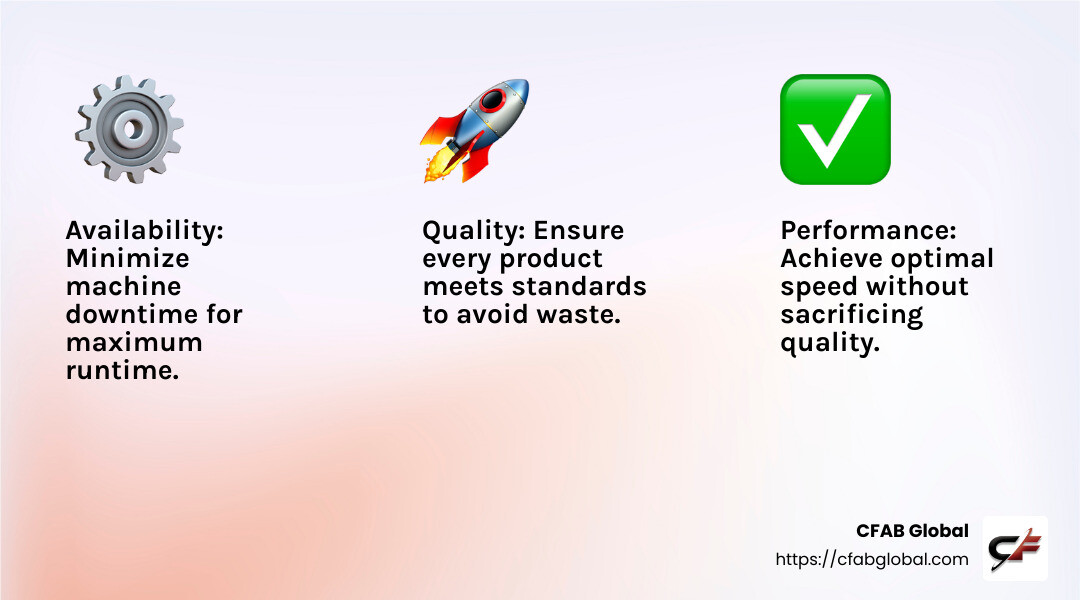

When we talk about industrial machinery efficiency, we’re diving into a world where every bit of energy, time, and material counts. It’s all about getting the most out of what you put in, and it hinges on three key metrics: availability, performance, and quality.

Key Metrics

-

Availability: This is about keeping machines running as much as possible. Downtime is the enemy here, whether from maintenance or unexpected breakdowns. Machines need to be ready to roll when you need them.

-

Performance: It’s not just about running; it’s about running well. Machines should operate at their best speed without cutting corners on quality. Any slow-downs or stops can hurt overall efficiency.

-

Quality: Producing high-quality products is non-negotiable. If a machine churns out defective goods, it’s wasting resources. Quality checks ensure that what’s produced meets the standards every time.

Calculating Efficiency

To measure how well machines are doing, we use formulas like Overall Equipment Effectiveness (OEE). OEE combines those three metrics—availability, performance, and quality—into one handy number that tells you how efficiently your machines are working.

The Efficiency Formula:

[ \text{Efficiency} = \left( \frac{\text{Useful Output}}{\text{Total Input}} \right) \times 100 ]

This basic formula helps in calculating how much of the input (like energy or raw materials) is being turned into useful output.

OEE Calculation:

[ \text{OEE} = \text{Availability} \times \text{Performance} \times \text{Quality} ]

- Availability: Time the machine is up and running.

- Performance: Speed at which it operates compared to its maximum.

- Quality: Percentage of good products produced over total production.

A perfect OEE score is 100%, meaning your machines are running perfectly with no downtime, at full speed, and producing high-quality products.

Tracking these metrics lets you pinpoint where improvements are needed. For instance, if availability is low, you might need to focus on reducing downtime through better maintenance or faster changeovers. If performance is lagging, it might be time to look at optimizing machine speed or addressing bottlenecks.

Incorporating these concepts into your operations means you can boost your industrial machinery efficiency and, in turn, improve your bottom line. With companies like BE Machinery offering cutting-edge food packaging solutions, and Graco providing top-notch automated lubrication systems, there are tools and technologies available to help you achieve these efficiency goals.

Strategies to Improve Industrial Machinery Efficiency

To truly rev up your machinery and boost industrial machinery efficiency, you need a mix of smart maintenance strategies and hands-on operator training. Here’s how these elements come together to keep your machines humming.

Maintenance Approaches

- Preventive Maintenance:

Think of this as regular check-ups for your machines. Scheduled activities like inspections, fluid replacements, and minor repairs can stop problems before they start. This proactive approach helps reduce unexpected breakdowns and keeps production rolling smoothly.

- Predictive Maintenance:

This is all about using data to predict when a machine might fail. Techniques like vibration analysis and thermography help spot issues early. By addressing these potential problems before they cause downtime, you can save time and money.

- Corrective Maintenance:

Sometimes, things break despite your best efforts. Corrective maintenance involves fixing these issues quickly to minimize disruption. It can be as simple as adjusting a part or replacing a worn component.

- Total Productive Maintenance (TPM):

TPM involves everyone in the maintenance process. Operators perform simple tasks like cleaning and fluid checks, freeing up skilled technicians for complex jobs. This team effort ensures machines run at peak performance.

Operator Training

Proper training is crucial for ensuring that operators can handle machinery effectively and safely. Here’s what to focus on:

- Machine Functionality:

Operators should understand how each machine works, including its quirks and capabilities. This knowledge helps them troubleshoot issues and optimize performance.

- Collaboration:

Encourage operators to work closely with maintenance teams. Sharing insights and observations can lead to quicker problem-solving and more efficient operations.

- Ongoing Education:

Machinery and technology are constantly evolving. Regular training sessions keep operators up-to-date with the latest techniques and tools, ensuring they can make the most of new advancements.

By combining these maintenance strategies with thorough operator training, you can significantly improve industrial machinery efficiency. It’s not just about fixing what’s broken but about creating a culture of continuous improvement and collaboration.

Incorporating solutions from industry leaders like BE Machinery and Graco can further streamline your maintenance processes. Their advanced technologies and systems are designed to keep your machinery running smoothly and efficiently.

The Role of Technology in Boosting Efficiency

In the world of manufacturing, technology plays a crucial role in enhancing industrial machinery efficiency. From automation to analytics, these technological advancements are changing how industries operate, making them more productive and cost-effective.

Advanced Solutions

Automation is the backbone of modern industrial efficiency. By automating repetitive and time-consuming tasks, manufacturers can reduce human error and increase productivity. For instance, automatic grease and oil pumping solutions from Graco help keep machinery well-lubricated without constant manual intervention, ensuring seamless operations.

Analytics is another game-changer. Advanced data platforms collect and analyze machine data in real-time, providing insights into performance and potential issues. This data-driven approach allows for quick decision-making and helps identify areas for improvement. Implementing these insights can boost machine efficiency and boost overall production.

Energy Management is essential for achieving peak operational efficiency. By optimizing energy consumption, companies can reduce costs and minimize their environmental footprint. Automated systems that monitor and adjust energy usage in real-time are key to maintaining this balance.

When it comes to specialized solutions, BE Machinery offers cutting-edge technologies like Automatic CIP Cleaning Systems, which ensure thorough and efficient cleaning of industrial equipment, reducing downtime and improving product quality. Their packaging solutions, including Hygiene Rotary Fillers and Box Folding Line machines, are designed to maximize efficiency and minimize waste.

For fluid management, Graco provides innovative solutions that streamline the handling of industrial fluids, ensuring precise control and minimal waste. Their Auto Lube Controllers and Flow Divider Valves are excellent examples of how automation can improve machinery efficiency.

In the field of lubricants, Texas Refinery Corp offers specialized products that ensure machinery operates smoothly under various conditions. Their high-quality oils and greases reduce friction and wear, extending the lifespan of equipment and maintaining optimal performance.

By integrating these advanced solutions, manufacturers can significantly improve their industrial machinery efficiency, leading to increased productivity, reduced costs, and a more sustainable operation. Embracing technology not only helps in tackling current challenges but also prepares industries for future advancements.

Frequently Asked Questions about Industrial Machinery Efficiency

What is industrial production efficiency?

Industrial production efficiency is all about getting the most out of your resources. It means maximizing output while minimizing inputs like time, materials, and energy. Imagine a factory that produces more goods with less waste and effort—that’s a model of efficiency. In this context, industrial machinery efficiency is key. It ensures machines run smoothly, with minimal downtime, and produce high-quality products consistently.

How do you calculate industrial efficiency?

Calculating industrial efficiency involves several metrics, but one of the most popular is Overall Equipment Efficiency (OEE). This metric gives a comprehensive view of how well a manufacturing process is performing.

OEE is calculated by multiplying three factors:

- Availability: Measures the actual production time vs. planned production time. It accounts for downtimes like maintenance or breakdowns.

- Performance: Compares the actual production speed to the ideal speed. It identifies slowdowns or minor stoppages.

- Quality: Assesses the percentage of products meeting quality standards without defects.

The formula looks like this:

[ \text{OEE} = \text{Availability} \times \text{Performance} \times \text{Quality} ]

What does 85% OEE mean?

An OEE score of 85% is considered world-class. It indicates that the equipment is running at 85% of its full potential, factoring in availability, performance, and quality. Here’s what it means practically:

- Availability: The machine is running most of the time it’s supposed to, with minimal downtime.

- Performance: It operates close to its maximum speed.

- Quality: The majority of products produced are defect-free.

Achieving such a score suggests that the manufacturing process is highly efficient, with room for improvement. However, it’s important to note that reaching an OEE of 100% is extremely rare, as some inefficiencies are always present. Instead, the goal is continuous improvement, using OEE as a benchmark to identify and address inefficiencies.

Conclusion

At CFAB Global, we understand the importance of industrial machinery efficiency in today’s competitive landscape. Our mission is to help businesses maximize their machinery’s potential through our exclusive Machine Reliability Program. This program is not just a service; it’s a partnership aimed at enhancing performance, reducing downtime, and extending the lifespan of your machinery.

Our Machine Reliability Program stands out because it offers customized solutions custom to your specific needs. We don’t believe in a one-size-fits-all approach. Instead, we work closely with each client to design strategies that address their unique challenges and goals. This personalized attention ensures that your machinery operates at peak efficiency, delivering measurable results that impact your bottom line.

Through proactive maintenance, expert analysis, and cutting-edge technology, we empower your business to achieve maximum productivity. Our team of specialists is dedicated to providing the highest level of support, ensuring that your equipment runs smoothly and efficiently.

Choose CFAB Global as your trusted partner in industrial machinery solutions. With our expertise and commitment to your success, we’re here to help you rev up your machinery and drive your business forward.