Grain storage challenges and the importance of efficient reclaim systems are at the forefront of what we need to talk about when it comes to safeguarding our agricultural yields. Whether you’re a small family farm or a large agricultural conglomerate, the issues are universally the same: how to store large quantities of grain safely and how to access it efficiently when needed.

Grain storage isn’t just about keeping the rain off and the rodents out; it’s about protecting the grain from spoilage, contamination, and loss. This is where reclaim systems come into play. They are the unsung heroes of the grain storage world, ensuring that stored grain can be retrieved cleanly, safely, and without causing damage or loss to the product.

Why is an efficient reclaim system important?

1. Safety: First and foremost, safety is a primary concern. Traditional methods of grain retrieval often require personnel to enter storage units, posing significant risks.

2. Efficiency: Time is money. Efficient reclaim systems ensure that grain can be moved quickly from storage to transport or processing.

3. Quality Control: Retrieval processes can impact grain quality. Advanced systems like VibraFloor provide gentle handling, preserving integrity and value.

4. Cost-Effective: An efficient system reduces labor costs and operational downtime, enhancing overall profitability.

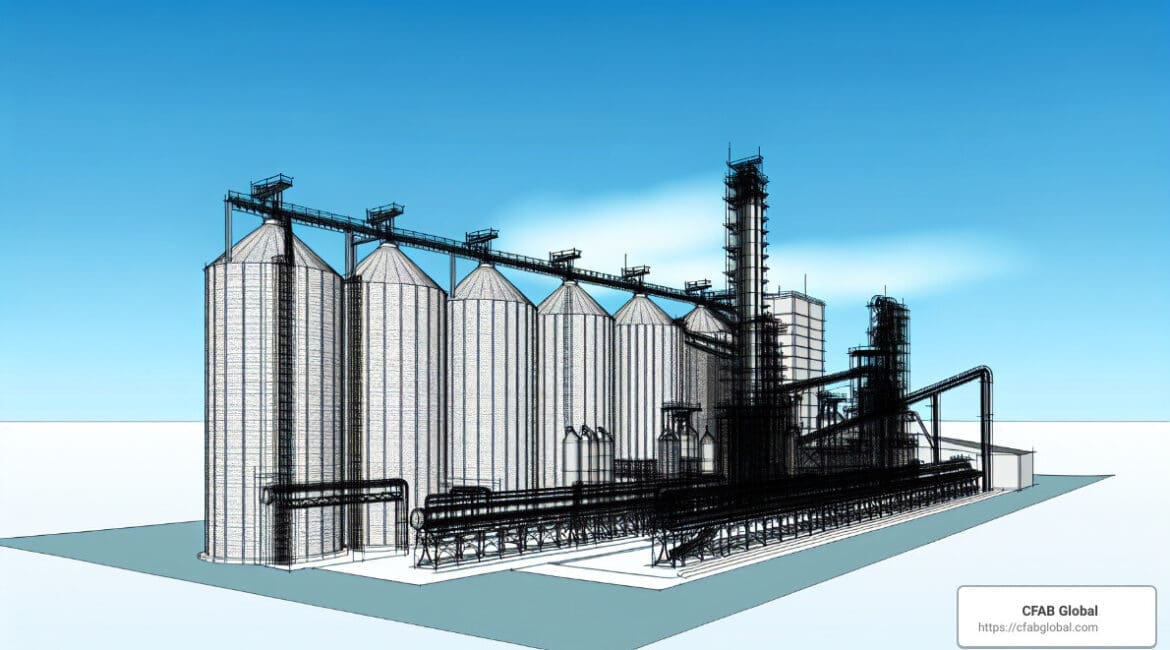

At CFAB Global, our focus is on bringing you solutions like VibraFloor, a fully automated, zero-entry grain reclaim system. It’s a game-changer for any grain storage facility, providing a safe, efficient, and cost-effective solution to a challenge as old as farming itself. It can handle any type of grain, biomass, wood chips, and more, making it a versatile addition to your operation.

Let’s dive deeper into grain reclaim systems and uncover how adopting the right strategies can safeguard your crop, reduce costs, and streamline your operations.

Understanding Grain Reclaim Systems

When it comes to managing and retrieving stored grain efficiently, the choice of the right reclaim system is crucial. Let’s explore the various types of systems available, their benefits, and key components.

Cantilever Systems

Cantilever systems are designed for versatility and can handle a wide range of materials in flat-bottom storage structures. These systems can be hydraulically or electrically driven and may feature single or dual augers depending on the specific needs of the operation. The flexibility in design allows for customized solutions to meet the unique challenges of different materials.

Cone-Bottom Systems

For materials that have moderate-to-poor flow characteristics, cone-bottom systems offer an efficient solution. These systems are fully automated, ensuring that material reclaim is as smooth as possible. A standout feature is the zero-entry maintenance capability, which enhances safety by eliminating the need for personnel to enter the silo.

CleanSweep Systems

The CleanSweep system is tailored for semi-free-flowing materials, utilizing a wheel-supported auger for reclaim. It’s designed for high-volume storage and provides a fully-automated cleanout solution, which significantly reduces the need for manual intervention. Its unique reversing capability adds an extra layer of flexibility.

Track-Drive Systems

In environments where the material has poor flow characteristics or when a higher volume delivery is needed, track-drive systems are the go-to solution. These systems are built for automated, continuous operation under challenging conditions, ensuring reliability and efficiency in material handling.

Fluidized Screw

The Fluidized Screw system is ideal for fluidizable bulk materials such as cements and powders. It combines an air-gravity conveying system with a mechanical screw conveyor, offering a solution that can confidently handle hard pack materials. This system is a testament to the innovative integration of technologies for improved material handling.

Benefits of adopting these systems include:

– Automation reduces labor costs and enhances process efficiency.

– Safety is significantly improved with zero-entry solutions like the Cone-Bottom and CleanSweep systems.

– Flexibility in system design allows for tailored solutions to meet specific operational needs.

– Reliability of these systems ensures continuous operation, essential for meeting today’s agricultural demands.

Key components across these systems may vary but generally include augers, hydraulic or electric drives, and specialized mechanisms for material movement (such as the wheel-supported auger in CleanSweep systems or the air-gravity system in Fluidized Screws).

Understanding the specific challenges and requirements of your grain storage and reclaim needs is the first step towards choosing the right system. Whether dealing with semi-free-flowing materials or needing a high-volume, fully automated reclaim solution, there’s a system designed to meet those needs efficiently and safely.

With the wide range of applications and the critical importance of safety, efficiency, and reliability in grain storage and handling, the VibraFloor system stands out as a fully automated, no-entry solution. It’s designed to work with any grain, bio-mass, wood chips, cement products, ddgs, and other products, offering unparalleled flexibility and safety.

We’ll delve into the role of grain reclaim systems in agriculture, highlighting their impact on operational efficiency, safety, customization possibilities, and the importance of reliable maintenance and after-sale service.

The Role of Grain Reclaim Systems in Agriculture

Grain reclaim systems play a pivotal role in modern agriculture, streamlining operations, ensuring safety, offering unmatched flexibility, and guaranteeing reliability. Let’s explore how these systems transform the agricultural sector.

Efficiency in Operation

At the heart of agricultural efficiency is the ability to move and manage grain swiftly and effectively. Grain reclaim systems significantly contribute to this by automating the process of moving grain from storage facilities to transportation or processing units. This automation translates to reduced labor costs and minimizes the time it takes to get products to market. For instance, systems like VibraFloor eliminate the need for manual intervention, further enhancing operational efficiency.

Enhancing Safety

Safety in grain storage and handling is paramount. Traditional methods often require workers to enter potentially dangerous environments. However, zero-entry solutions like VibraFloor have revolutionized safety standards. By fully automating the reclaim process, these systems ensure that no human has to enter a silo or storage unit, effectively eliminating the risk of accidents. This No Entry = No Rescue approach is not just a safety measure but a new standard in agricultural operations.

Flexibility and Customization

Agriculture is not a one-size-fits-all industry. Different grains and products have unique handling and storage requirements. Reclaim systems offer tailored solutions that can adapt to a wide range of materials, from grains to biomass and even cement products. The ability to customize these systems to specific needs means that agricultural operations can maintain high efficiency regardless of the product type or storage conditions.

Reliability and Maintenance

In agriculture, time is of the essence. Downtime can lead to significant losses, making reliability a critical factor in choosing a grain reclaim system. Systems designed for 24/7/365 operation ensure that agricultural processes can continue without interruption. Furthermore, companies like CFAB Global provide after-sale service, ensuring that any issues can be swiftly addressed without impacting the agricultural operation’s efficiency. This level of support is not just about fixing problems; it’s about building a partnership that supports the agricultural industry’s evolving needs.

In conclusion, grain reclaim systems are more than just equipment; they are an integral part of modern agriculture’s success. By offering solutions that enhance efficiency, ensure safety, provide flexibility, and guarantee reliability, these systems are helping to shape the future of farming. As we continue to explore the advancements in this field, it’s clear that choosing the right system and partner, like CFAB Global, is crucial for any agricultural operation aiming for success in today’s competitive landscape.

Frequently Asked Questions about Grain Reclaim Systems

How do grain reclaim systems improve process efficiency?

Grain reclaim systems significantly enhance process efficiency in several key ways:

-

Automation: By automating the process of moving grain from storage to processing or transportation, these systems reduce the need for manual labor. This not only speeds up operations but also minimizes the risk of human error.

-

Continuous Operation: Many reclaim systems are designed for 24/7 operation, ensuring that grain can be moved as needed without delays. This is crucial during peak harvest or processing times when demand is high.

-

Minimized Downtime: With features like VibraFloor, which is a fully automated, no-entry system, maintenance and cleaning downtimes are significantly reduced. This system doesn’t require human intervention inside the structure, which means operations can continue without interruption.

What safety features are important in grain reclaim systems?

Safety is paramount in the design and operation of grain reclaim systems. Important safety features include:

-

Zero-Entry Maintenance: Systems like VibraFloor offer a no-entry = no-rescue solution. This means that the system is designed in such a way that human entry into potentially dangerous confined spaces, like silos or bins, is not required for maintenance or operation, significantly reducing the risk of accidents.

-

Automated Controls: Automated systems ensure that the operation can be monitored and controlled remotely, reducing the need for personnel to be in close proximity to potentially hazardous machinery.

-

Dust Control: Grain handling can produce a lot of dust, which is not only a health hazard but also a potential explosion risk. Effective reclaim systems incorporate dust control measures to mitigate these risks.

Can grain reclaim systems be customized for specific needs?

Absolutely. One of the strengths of modern grain reclaim systems is their flexibility and customization. Whether you’re dealing with grain, bio-mass, wood chips, cement products, or ddgs, systems can be tailored to meet the specific needs of your operation. Factors such as:

-

Material Type: Different materials have different handling requirements. Systems can be customized to accommodate the specific flow characteristics and storage needs of the material you’re working with.

-

Volume and Scale: Whether you’re a small operation or a large industrial facility, reclaim systems can be scaled to match your volume requirements, ensuring efficient operation without over or under-capacity issues.

-

Space Constraints: Custom solutions can be designed to fit the available space, whether you’re integrating into an existing facility or building a new one.

In conclusion, grain reclaim systems like VibraFloor offer a blend of efficiency, safety, and customization that can significantly enhance the operational capabilities of agricultural and industrial operations. With the support of a knowledgeable partner like CFAB Global, finding the right system tailored to your specific needs is straightforward, ensuring your operation is as efficient, safe, and productive as possible. The importance of such innovative solutions in the agricultural sector cannot be overstated.

Innovative Solutions in Grain Reclaim Systems

In the realm of grain storage and handling, the quest for more efficient, safer, and smarter solutions is ongoing. One standout innovation in this area is VibraFloor, a system that is revolutionizing the way we think about grain reclaim systems. Let’s dive into how VibraFloor offers a No Entry = No Rescue solution and why its fully automated nature sets a new standard in the industry.

VibraFloor: A Game-Changer

VibraFloor is not just another grain reclaim system; it’s a leap forward. What sets VibraFloor apart is its unique mechanism that eliminates the need for human entry into potentially dangerous storage areas. This is crucial because it significantly reduces the risk of accidents and injuries associated with manual operations inside silos or storage bins.

The system works by creating a gentle vibration across the floor of the storage area, encouraging the grain or other stored materials to move toward the reclaim area. This process is not only efficient but also ensures a more complete emptying of the storage space, reducing waste and improving turnover times.

No Entry = No Rescue

The No Entry = No Rescue philosophy behind VibraFloor is a testament to the system’s safety benefits. By designing a system that requires no human intervention inside the structure, VibraFloor drastically cuts down the risk of entrapment or injury, which are serious concerns in the grain handling industry. This approach not only enhances safety but also aligns with stringent safety regulations, providing peace of mind for both operators and business owners.

Fully Automated for Efficiency and Reliability

VibraFloor’s fully automated nature is another key feature. Automation translates to fewer manual tasks, reducing labor costs and minimizing the chances of human error. This level of automation ensures a consistent and reliable operation, which is crucial for maintaining the flow of materials and the efficiency of the storage system.

Moreover, the versatility of VibraFloor means it can handle a wide range of materials beyond grain, including bio-mass, wood chips, cement products, and ddgs. This flexibility makes it an ideal solution for various industries, from agriculture to bioenergy and construction.

Conclusion

As we look toward the future of grain storage and handling, innovations like VibraFloor are setting new standards for efficiency, safety, and automation. The No Entry = No Rescue approach not only enhances safety but also exemplifies the kind of innovative thinking that will drive the industry forward. With solutions like these, operators can expect not just to meet their current needs but to be well-prepared for the challenges of tomorrow.

As we transition from discussing these innovative solutions, it’s clear that the importance of choosing the right system cannot be overstated. With the support of CFAB Global and their cutting-edge offerings like VibraFloor, the path toward more efficient, safe, and productive grain handling operations is clearer than ever.

Conclusion

Choosing the right reclaim system grain is pivotal for the success of any grain handling and storage operation. The right system not only addresses current needs but also anticipates future challenges, ensuring longevity and adaptability in a fast-evolving agricultural landscape. This is where CFAB Global steps in, offering unparalleled support and state-of-the-art solutions like VibraFloor to meet these demands.

VibraFloor stands out as a solution in the realm of grain reclaim systems. Its fully automated, no-entry design not only enhances operational efficiency but also significantly improves safety by eliminating the need for human intervention inside storage structures. This feature is crucial, aligning with the “No Entry = No Rescue” principle and ensuring a safer working environment for everyone involved.

Moreover, the versatility of VibraFloor allows it to handle a wide array of materials beyond grain, including biomass, wood chips, cement products, and DDGS. This adaptability makes it an invaluable asset for various applications, ensuring that whatever your storage needs, VibraFloor can meet them effectively.

At CFAB Global, we understand that every operation is unique, with its own set of requirements and challenges. That’s why we’re committed to providing not just products but solutions. Our team works closely with you to understand your specific needs, offering tailored systems that optimize your operation’s efficiency, safety, and reliability.

Choosing the right grain reclaim system is a decision that impacts not just your current operations but your ability to grow and adapt to the future. With CFAB Global’s support and innovative solutions like VibraFloor, you’re not just investing in a system; you’re investing in the future of your operation.

Discover how CFAB Global can empower your grain handling and storage operations. Explore our services and find the perfect solution tailored to your needs. Learn more about our services and how we can support your operation.

Together, let’s build a safer, more efficient, and more productive future in grain handling and storage.