Proportional flow divider valve is a crucial component in hydraulic systems, significantly improving flow control and actuator management. These valves ensure that the hydraulic power is evenly distributed among multiple actuators, allowing for smooth operation and consistent performance.

Key highlights of proportional flow divider valves:

- Flow Control: Balances hydraulic power among multiple lines.

- Actuator Management: Synchronizes movement across different actuators.

- Efficiency: Improves overall system performance and longevity.

Every line of products CFAB Global offers aims to increase production efficiency and reduce downtime—these valves are no exception.

I’m Todd Cleppe, the CEO of CFAB Global. With over 25 years of expertise, I’ve worked extensively with the proportional flow divider valve to improve machinery reliability. Next, let’s dive into understanding how these valves contribute to hydraulic systems’ efficiency.

Explore more about proportional flow divider valve:

– adjustable flow divider

– pressure compensated flow divider

– priority flow divider valve

Understanding Proportional Flow Divider Valves

Proportional flow divider valves are vital in hydraulic systems. They ensure hydraulic power is distributed evenly among multiple actuators. This balance is crucial for smooth and consistent operation.

Hydraulic Proportional Flow Divider

A hydraulic proportional flow divider splits a single flow of hydraulic fluid into two or more streams. This division allows for precise control of each actuator connected to the system. The Prince Proportional Flow Divider RD-350-AB-16 is an example of such a valve. It offers a flow rate of 16 GPM with a divider ratio of 80:20, ensuring efficient power distribution at 3000 PSI.

Flow Divider Valves

Flow divider valves are designed to handle variations in flow demand. They adjust automatically to maintain a constant flow rate, regardless of changes in pressure or fluid viscosity. This adaptability is essential for applications where multiple actuators need to operate simultaneously without losing synchronization.

Control Multiple Actuators

One of the main advantages of using proportional flow divider valves is their ability to control multiple actuators effectively. By splitting the hydraulic flow into proportional streams, these valves ensure each actuator receives the right amount of power. This control is crucial in complex machinery where precise movement and synchronization are required.

In industries like food processing, maintaining such precision is essential. Systems like the Automatic CIP Cleaning Systems from BE Machinery rely on this precision to ensure high hygiene standards. These systems use proportional flow divider valves to manage the cleaning cycles efficiently, enhancing the overall reliability and performance of the equipment.

Understanding how these valves work and their benefits can significantly improve your hydraulic systems’ efficiency and longevity. Next, we’ll explore some of the top proportional flow divider valves available today.

Top Proportional Flow Divider Valves

Prince Proportional Flow Divider RD-350-AB-16

The Prince Proportional Flow Divider RD-350-AB-16 is a standout in hydraulic flow control. Designed to handle a flow rate of 16 gallons per minute (GPM), this valve ensures precise and efficient distribution of hydraulic fluid.

Key Features:

-

Flow Capacity: With a capacity of 16 GPM, this flow divider is ideal for applications requiring moderate flow rates, ensuring consistent performance across various hydraulic systems.

-

Port Size: Equipped with a 1/2″ NPT port, it offers a standard connection size that fits seamlessly into many hydraulic setups, making installation straightforward and hassle-free.

-

Pressure Handling: This valve can withstand pressures up to 3000 PSI, making it robust enough for demanding environments where high pressure is a constant factor.

-

Divider Ratio: The 80:20 divider ratio is a unique feature, allowing the valve to split the flow in a way that 80% goes to one outlet and 20% to the other. This precise control is crucial for applications where unequal flow distribution is necessary for optimal performance.

Applications and Benefits:

The RD-350-AB-16 is particularly effective in systems that require different flow rates to multiple actuators. For instance, in industrial machinery where one actuator needs more power than another, this valve’s 80:20 split ensures each component receives the exact flow required.

Such precision is invaluable in industries like food processing, where equipment like the Hygiene Rotary Filler & Capper from BE Machinery demands exact flow control to maintain high hygiene standards and efficiency.

By integrating the Prince Proportional Flow Divider RD-350-AB-16 into your hydraulic system, you can achieve improved synchronization and efficiency, reducing wear and tear on your equipment and extending its lifespan.

Next, let’s dig into how proportional flow divider valves function to provide these benefits.

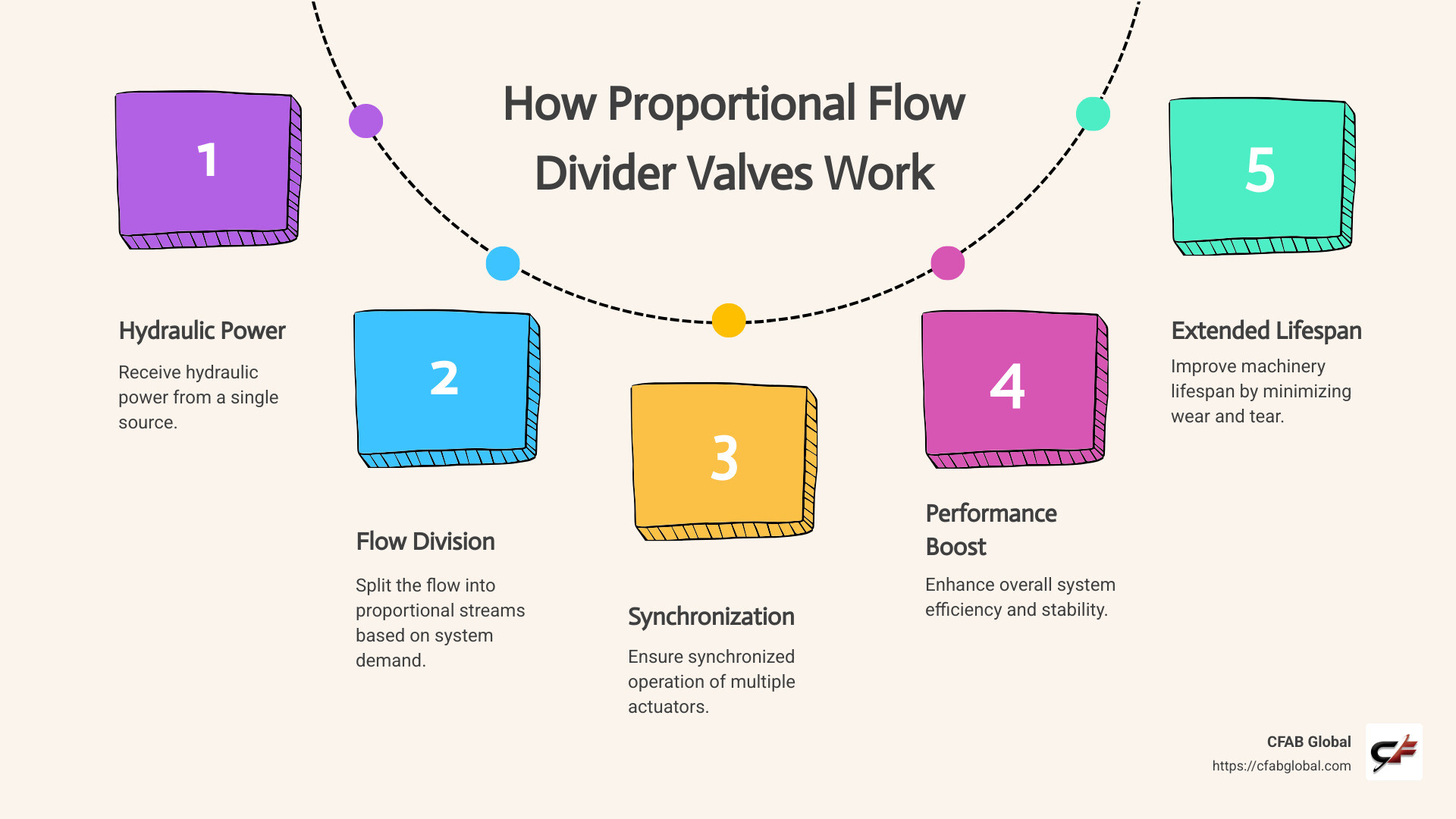

How Proportional Flow Divider Valves Work

Hydraulic flow division is a key function of proportional flow divider valves. These valves are designed to split a single flow of hydraulic fluid into two or more proportional streams. This division is crucial in systems where multiple actuators need to be controlled simultaneously, ensuring each actuator gets the appropriate flow needed for its operation.

Proportional streams are achieved through the valve’s ability to provide precise control over the distribution of fluid. For example, a valve with an 80:20 divider ratio allocates 80% of the input flow to one outlet and 20% to the other. This specific distribution is essential in applications where different actuators require varied amounts of hydraulic fluid to function optimally.

Actuator control is improved by using proportional flow divider valves. By delivering the exact flow rate needed for each actuator, these valves ensure that all components in a hydraulic system work in harmony. This synchronization is especially beneficial in complex machinery, such as those used in the food processing industry, where precise flow control can impact the quality and efficiency of operations. For instance, equipment like the Hygiene Rotary Filler & Capper benefits from such precision, maintaining high standards of hygiene and performance. When considering solutions for such equipment, BE Machinery’s packaging solutions offer excellent options.

In summary, the functionality of proportional flow divider valves lies in their ability to manage hydraulic flow division, create proportional streams, and improve actuator control. This capability not only improves system efficiency but also extends the lifespan of machinery by reducing unnecessary wear and tear.

Next, we’ll explore the benefits of using these valves in various hydraulic systems.

Benefits of Using Proportional Flow Divider Valves

Equal Flow Delivery

One of the standout features of proportional flow divider valves is their ability to deliver equal flow to multiple actuators. This ensures that each actuator receives the precise amount of hydraulic fluid it needs, which is crucial for maintaining balance and performance in complex systems. Imagine a scenario in a manufacturing plant where two robotic arms need to move in perfect harmony. By using a proportional flow divider valve, each arm gets the exact flow needed for synchronized movement, preventing any lag or mismatch in operations.

Hydraulic System Efficiency

Efficiency is a top priority in any hydraulic system. Proportional flow divider valves contribute significantly to this by optimizing the distribution of hydraulic fluid. By ensuring that the fluid is evenly divided and delivered, these valves reduce energy waste and improve the overall efficiency of the system. This is particularly beneficial in industries like food processing, where efficient fluid management can lead to faster production times and reduced operational costs. For instance, equipment such as the Box Folding Line Machines can operate more smoothly and with less downtime thanks to efficient hydraulic fluid distribution.

Actuator Synchronization

In systems with multiple actuators, synchronization is key. Proportional flow divider valves play a crucial role in achieving this by ensuring that all actuators operate in unison. This is particularly important in applications where precise timing and coordination are required, such as automated assembly lines. Synchronization not only improves the quality of the final product but also minimizes wear on the actuators, extending their lifespan and reducing maintenance costs.

In summary, the use of proportional flow divider valves improves hydraulic system performance by ensuring equal flow delivery, boosting efficiency, and enabling precise actuator synchronization. These benefits make them an invaluable component in a wide range of industrial applications.

Next, we’ll address some frequently asked questions about these versatile valves.

Frequently Asked Questions about Proportional Flow Divider Valves

How does a proportional flow divider work?

A proportional flow divider valve is designed to split hydraulic flow into proportional streams. This ensures that each actuator in a system receives a specific amount of hydraulic fluid, allowing for precise control over multiple actuators. Imagine a scenario where two conveyor belts need to move at the same speed. The flow divider valve ensures that both belts receive equal hydraulic flow, maintaining synchronized movement. This is crucial in applications like automated packaging systems, where timing and coordination are essential.

What is a proportional flow valve?

A proportional flow valve is a component that controls the output pressure and flow rate of hydraulic fluid. Unlike traditional valves that operate in an all-or-nothing manner, proportional flow valves allow for variable control. This means you can adjust the flow and pressure dynamically, depending on the needs of the system. The ability to fine-tune these parameters is beneficial in systems that require precise control, such as those used in food processing equipment like Hygiene Rotary Fillers.

What are the two types of proportional valves?

Proportional valves can be broadly categorized into two types: directional control valves and pressure control valves.

-

Directional Control Valves: These valves manage the direction of hydraulic fluid flow within a system. By controlling the path the fluid takes, they help in directing the movement of actuators. This is particularly useful in complex machinery where multiple movements are required simultaneously.

-

Pressure Control Valves: These valves regulate the pressure of the hydraulic fluid. By adjusting the pressure, they ensure that actuators operate within their optimal range, protecting them from damage due to excessive force. This is crucial in maintaining the longevity and reliability of hydraulic systems.

Both types of valves are essential for efficient flow control in hydraulic systems, and they work together to ensure smooth and precise operation.

Conclusion

At CFAB Global, we pride ourselves on being a trusted leader in advanced machinery solutions. Our Machine Reliability Program stands at the heart of our offerings, ensuring your machinery operates at peak performance. This program is not a one-size-fits-all solution; it’s custom to meet the unique needs of each client.

Our approach focuses on boosting the performance, reliability, and lifespan of critical machinery components. By providing personalized analysis and cutting-edge services, we help businesses achieve maximum productivity and reduce costly downtime. This ensures a better return on investment for your machinery.

CFAB Global serves a diverse range of industries, including manufacturing, construction, agriculture, and energy. Our custom solutions streamline production processes, improve machinery performance, and extend operational life. Whether you’re in need of hydraulic solutions or looking to improve your machinery’s efficiency, we have the expertise you need.

For more information on how CFAB Global can help you achieve your operational goals, visit our service page to explore our comprehensive solutions.

Your success is our commitment. Trust CFAB Global to keep your operations running smoothly and efficiently.