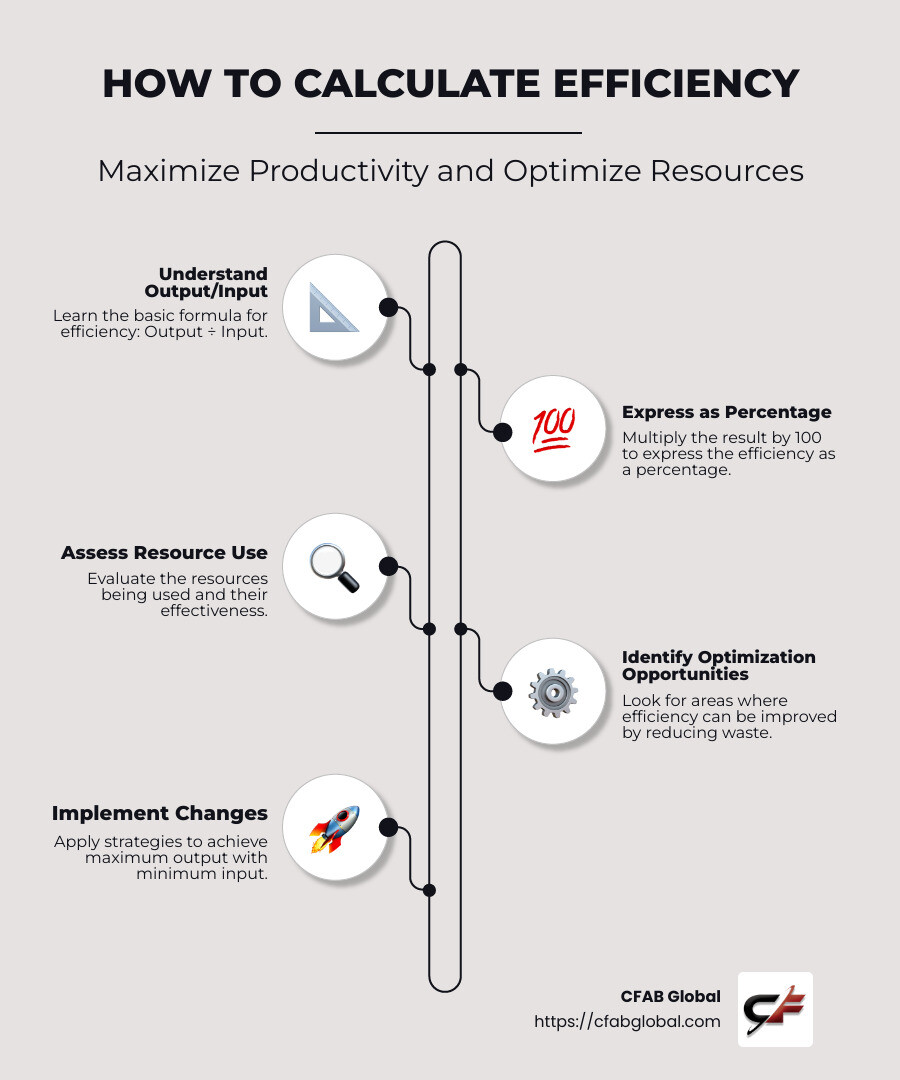

How to calculate efficiency is a vital question for businesses aiming to maximize productivity and optimize resource use. To quickly address this crucial question:

- Formula: Efficiency = Output ÷ Input

- Express as Percentage: Multiply the result by 100 for a percentage.

- Aim: Achieve maximum output with minimum input.

This formula measures how well you are using resources to produce desired outcomes, ensuring no waste of time, energy, or materials. For industries reliant on machinery, like manufacturing and agriculture, understanding this can transform operations by reducing downtime and boosting production levels. For example, BE Machinery offers cutting-edge food processing solutions that exemplify optimized efficiency through advanced designs and technology.

Introducing myself, I’m Todd Cleppe, with over 25 years of experience in improving machinery efficiency. Crafting automated solutions that reduced equipment failures by 40% early in my career was a pivotal moment, demonstrating the profound impact of efficiency optimization.

Understanding Efficiency

Efficiency is all about getting the most out of what you have. It’s like squeezing every drop out of a lemon. Let’s explore three important types of efficiency: economic efficiency, market efficiency, and operational efficiency.

Economic Efficiency

Imagine a world where you get the best bang for your buck. That’s economic efficiency! It’s about using resources in a way that maximizes output without wasting anything. Think of it like a farmer using the least amount of water and fertilizer to grow the most crops. The goal is to serve everyone in the economy as effectively as possible, making sure goods hit the market at the lowest cost and labor is super productive.

Market Efficiency

Now, let’s talk about market efficiency. Picture a stock market where all the prices are just right. There’s no way to get a sneaky deal because all available information is already factored in. This concept was formalized by Eugene Fama in 1970 through the efficient market hypothesis. According to this hypothesis, you can’t beat the market because there are no undervalued or overvalued stocks waiting to be finded. Everything is perfectly aligned, just like a well-tuned orchestra.

Operational Efficiency

Operational efficiency is like running a tight ship. It’s about optimizing processes to reduce waste and increase productivity. In a factory setting, this could mean cutting down on the time it takes to switch from one product to another or ensuring machines run smoothly without hiccups. For example, BE Machinery provides top-notch food processing equipment, like their Automatic CIP Cleaning Systems, which help streamline operations and boost production levels with minimal resource use.

By understanding these types of efficiency, businesses can not only save costs but also improve their bottom line. It’s all about using what you have in the smartest way possible to achieve your goals.

How to Calculate Efficiency

Calculating efficiency is like finding out just how well you’re using your resources. Here’s a simple guide to how to calculate efficiency using the efficiency formula.

Efficiency Formula

The efficiency formula is straightforward:

[ \text{Efficiency} = \left( \frac{\text{Output}}{\text{Input}} \right) \times 100 ]

This formula gives you the efficiency percentage, telling you how much of your input is effectively turned into output. If you’re getting an efficiency of 80%, that means 80% of your input is being converted into useful output.

Output/Input Ratio

The output/input ratio is the heart of the efficiency formula. It’s about comparing what you get out (output) with what you put in (input). For example, in manufacturing, if you use 100 units of energy to produce 80 units of product, your output/input ratio is 0.8.

In industries like food processing, using efficient equipment can significantly improve this ratio. For instance, BE Machinery offers Hygiene Rotary Fillers that maximize output while minimizing resource input, elevating overall efficiency.

Percentage Calculation

Once you have your output/input ratio, multiply it by 100 to get a percentage. This percentage is a clear, easy-to-understand measure of efficiency. A higher percentage means greater efficiency, as more input is turned into useful output.

For example, in agriculture, using Texas Refinery Corp’s premium lubricants can improve the efficiency of machinery, ensuring more of the input energy is converted into productive work.

By mastering these calculations, you can optimize processes, save resources, and boost productivity across various sectors. Understanding how to calculate efficiency is a crucial step towards success in any industry.

Types of Efficiency

Efficiency isn’t just a one-size-fits-all concept. It comes in different forms, each crucial for maximizing performance in various sectors. Let’s explore the key types: energy efficiency, production efficiency, and machine efficiency.

Energy Efficiency

Energy efficiency is all about using less energy to perform the same task. Imagine a solar panel converting sunlight into electricity. The more electricity it produces from the same amount of sunlight, the higher its energy efficiency.

According to the US Department of Energy, energy costs can make up 96% of a motor’s life-cycle cost. Improving energy efficiency can lead to substantial savings and environmental benefits. For instance, Graco’s industrial fluid management solutions can help optimize energy use in manufacturing, reducing costs and environmental impact.

Production Efficiency

Production efficiency focuses on maximizing output while minimizing waste. It’s about producing more with less. In manufacturing, this means creating high-quality products without unnecessary resource use.

Consider two factories: one produces 100 widgets with 10% waste, while another produces the same amount with only 5% waste. The latter is more production-efficient. Using advanced equipment like BE Machinery’s Hygiene Rotary Fillers can improve production efficiency by reducing waste and improving output quality.

Machine Efficiency

Machine efficiency measures how well a machine converts input into useful work. It’s crucial in industries that rely heavily on machinery, like agriculture and construction.

For example, if a machine uses 500 kWh of energy to perform work worth 320 kWh, its efficiency is 64%. Improving machine efficiency can lead to better ROI and lower operating costs. Using Texas Refinery Corp’s premium lubricants can improve machine efficiency by reducing friction and wear, ensuring more input energy is converted into productive work.

By understanding these types of efficiency, businesses can tailor their strategies to optimize performance, reduce costs, and achieve sustainability goals. Whether it’s through energy-saving technologies, waste reduction, or enhancing machine performance, focusing on efficiency is a smart path to success.

Measuring Efficiency in Different Industries

Efficiency varies across industries, each with unique challenges and strategies for improvement. Let’s dig into how efficiency is measured in manufacturing, construction, agriculture, and energy sectors.

Manufacturing

In manufacturing, efficiency is about maximizing output and minimizing waste. It’s crucial for reducing costs and improving profitability. Machine efficiency plays a key role here. For example, using Graco’s industrial fluid management solutions can optimize energy use, enhancing machine performance and reducing waste. Additionally, BE Machinery’s Automatic CIP Cleaning Systems ensure hygiene and efficiency in food processing, cutting down on downtime and waste.

Construction

Efficiency in construction involves completing projects on time and within budget while minimizing resource use. This requires effective project management and the use of advanced machinery. Automated lubrication systems from Graco or Kecol can improve machine uptime and reduce maintenance costs, leading to more efficient operations. By focusing on machine efficiency, construction companies can achieve better project outcomes and reduce costs.

Agriculture

Agriculture efficiency is about maximizing crop yield while minimizing input costs. This can be achieved through precision farming techniques and efficient machinery. Graco’s bulk fluid handling solutions can help manage resources like water and fertilizers more effectively. Additionally, BE Machinery’s Box Folding Line Machines improve packaging efficiency, reducing waste and improving productivity.

Energy

In the energy sector, efficiency means generating more energy with fewer resources. This is crucial for reducing environmental impact and operational costs. Energy efficiency can be improved by adopting technologies that optimize energy use, like Graco’s Flow Divider Valves for better fluid management. By focusing on energy efficiency, companies can reduce their carbon footprint and improve sustainability.

In summary, measuring efficiency in different industries involves understanding unique challenges and leveraging the right tools and technologies. Whether it’s through advanced machinery, precision techniques, or energy optimization, improving efficiency is key to success in any sector.

Frequently Asked Questions about Efficiency

How do you measure efficiency?

Efficiency is often measured using the productivity ratio, which is a simple yet powerful concept. It involves comparing the output to the input. Think of it as how much you get out for what you put in. For businesses, this could mean how many products are made per hour of labor or how much revenue is generated per dollar spent.

In practical terms, if a factory produces 100 gadgets using 50 units of energy, the productivity ratio would be 2 gadgets per unit of energy. The higher the ratio, the more efficient the process.

What is the formula for working efficiency?

The formula for calculating working efficiency is straightforward:

[ \text{Efficiency} = \left( \frac{\text{Output}}{\text{Input}} \right) \times 100 ]

This formula gives you a percentage that represents how well resources are being used. For example, if a machine uses 100 units of energy to produce 80 units of work, its efficiency is 80%. This means 80% of the energy is converted into useful work, while 20% is lost, often as heat or friction.

How do I calculate energy efficiency?

Energy efficiency is calculated in much the same way as working efficiency. It’s the ratio of useful energy output to the energy input, expressed as a percentage:

[ \text{Energy Efficiency} = \left( \frac{\text{Energy Output}}{\text{Energy Input}} \right) \times 100 ]

For instance, if a light bulb uses 100 watts of electricity but only produces 60 watts of light, its energy efficiency is 60%. This is crucial in industries like manufacturing and energy production, where reducing waste and improving efficiency can lead to significant cost savings and environmental benefits.

Energy efficiency is not just about saving costs; it’s also about sustainability. By optimizing energy use, companies can reduce their carbon footprint and contribute to a greener planet.

Understanding and improving efficiency in various forms can lead to better productivity, lower costs, and a more sustainable future. Whether it’s through optimizing machinery with solutions from Graco or BE Machinery, or by adopting new energy-saving technologies, efficiency is a key driver of success.

Conclusion

At CFAB Global, we understand that achieving peak efficiency is not just a goal—it’s a pathway to success. Our Machine Reliability Program is at the heart of what we offer, providing a custom approach to improve the operational efficiency of your machinery. This isn’t a generic solution; it’s a customized strategy designed specifically for your business needs.

Why Choose CFAB Global?

Our unique program focuses on predictive maintenance and proactive strategies to minimize downtime, extend machinery lifespan, and maximize your return on investment. With our expertise, you can ensure your equipment operates at its best, reducing the risk of costly breakdowns and production delays.

By partnering with CFAB Global, you gain access to:

- Expertise: Our team brings years of experience and specialized knowledge to tackle your unique challenges.

- Customized Solutions: We tailor our services to meet the specific demands of your industry, whether it’s manufacturing, construction, agriculture, or energy.

- Proactive Maintenance: Our strategies focus on preventing issues before they occur, ensuring seamless operations.

We are committed to helping you achieve higher productivity and efficiency. Our Machine Reliability Program is not just about maintaining machinery—it’s about driving your business forward.

Ready to transform your machinery operations? Find how our solutions can help your business reach its full potential.

Efficiency is more than just a buzzword at CFAB Global. It’s a fundamental part of our mission to empower industries with the tools and strategies they need to succeed. Let’s work together to open up your business’s true potential.