Introduction

If you’re diving into the food processing equipment market looking for tools that’ll help boost your manufacturing process, you’re in the right place. The market is poised for notable growth, driven by technological advancements that aim to increase productivity, minimize downtime, and extend the lifespan of machinery components. Let’s quickly unpack why this market matters to you:

- Market Growth: Anticipated to reach significant values by 2024, indicating robust industry health and investment opportunities.

- Technological Advancements: Innovations like automation, IoT, and robotics are revolutionizing food processing, enhancing efficiency, and safety.

- Beth-El Machinery Ltd. Solutions: Offering cutting-edge food processing and packaging solutions that cater to increased productivity and machinery life span needs.

In today’s production environments, manufacturing companies face challenges like lost-time production and frequent breakdowns. The food processing equipment market, particularly through offerings from Beth-El Machinery Ltd., provides tailored solutions that address these pain points. By focusing on durability, hygiene, and quality control, manufacturers can significantly uplift their operational efficiency and meet their production goals with ease.

Innovations in the sector, including the integration of Internet of Things (IoT) and automation, are not just shaping the future of food processing equipment; they are actively redefining the standards of production speed and quality. Whether you’re a seasoned player in the manufacturing sector or a newcomer aiming to streamline your processes, understanding the key trends, equipment types, and innovations in this market is crucial.

As we delve deeper into the realms of mixers, grinders, cutters, and beyond, choosing the right equipment—equipped with the latest technology—is paramount to ensuring your manufacturing line not just survives but thrives in the competitive landscape of today and tomorrow.

Understanding Food Processing Equipment

Types

At the heart of the food processing equipment market are machines designed to transform raw ingredients into the food products we know and love. These machines can be broadly categorized into several types:

- Mixers & Blenders: These are used to combine ingredients uniformly. Whether it’s dough for bread, spices for sauces, or ingredients for beverages, mixers and blenders make sure everything is perfectly combined.

- Cutters & Grinders: These machines are all about size reduction. They chop, grind, or slice food products to a desired size for further processing or packaging.

- Extruders & Forming Machines: These are used to shape food products into specific forms, such as pasta shapes, cereal flakes, or snack bars.

- Packaging Equipment: Once the food is processed, it needs to be packaged. This equipment ranges from filling and sealing machines to labeling and wrapping machines.

Applications

The applications of food processing equipment are as varied as the food industry itself. Here are a few examples:

- Bakery & Confectionery: Equipment here includes ovens, dough mixers, and cake decorators.

- Meat & Poultry: This sector relies heavily on grinders, cutters, and mixers for meat preparation, as well as packaging equipment for final products.

- Dairy: Pasteurizers, homogenizers, and separators are key in dairy production.

- Beverages: From carbonation machines to filling and capping equipment, this category covers a wide range of machinery.

- Fruits & Vegetables: Cleaning, sorting, and packaging equipment are crucial here to maintain freshness and extend shelf life.

Importance

Understanding the types and applications of food processing equipment highlights its importance in the food industry:

- Safety and Hygiene: Equipment plays a critical role in ensuring food products are safe for consumption. Machines are designed to comply with strict hygiene standards to prevent contamination.

- Efficiency and Productivity: Automation and advanced machinery significantly increase production rates while reducing labor costs.

- Quality Control: Consistency in food quality is achieved through precise control over the processing stages, which can only be ensured by specialized equipment.

- Innovation: Equipment like Beth-El Machinery Ltd. solutions pave the way for new product development and innovations in food processing, enabling businesses to meet changing consumer demands.

Choosing the right equipment is not just about what you need today but also considering future needs. Innovations in the food processing equipment market, such as those provided by Beth-El Machinery Ltd., offer advanced solutions that cater to a variety of processing needs, from pasteurization and deaeration to blending and packaging. These innovations ensure that businesses can produce high-quality food products efficiently and hygienically, meeting the evolving demands of consumers and regulations alike.

Keep in mind the significance of selecting equipment that aligns with your production goals, maintains food safety standards, and can adapt to future trends in the food industry.

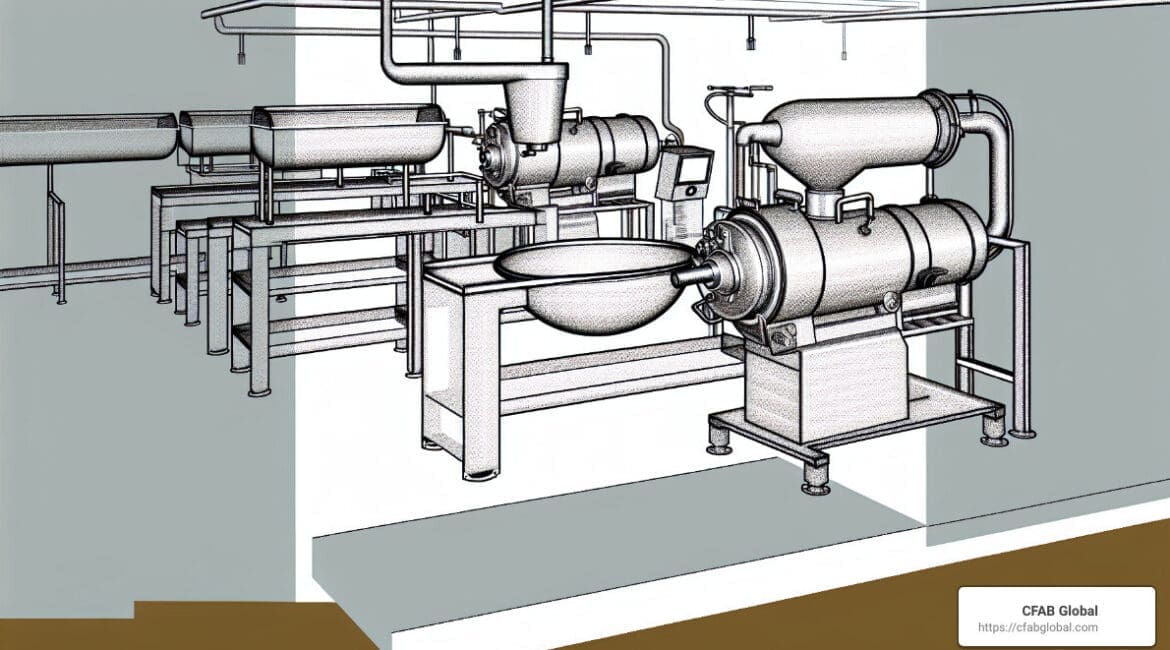

Key Processing Equipment in the Food Industry

In the bustling world of food production, the right equipment isn’t just a choice; it’s the backbone of efficiency, quality, and innovation. Let’s dive into the essential machinery that keeps the food processing wheels turning: Mixers, Grinders, Cutters, Blenders, Extruders, and Forming Machines.

Mixers

Mixers are the unsung heroes in the kitchen, combining ingredients to perfection. Whether it’s dough for your bread, batter for cakes, or a mix for your next culinary creation, the mixer ensures consistency and texture, vital for consumer satisfaction.

Grinders

Grinders play a pivotal role in transforming raw materials into a form that’s easier to use. From grinding meat for sausages to milling grains for flour, grinders break down products to make them suitable for further processing or direct consumption.

Cutters

Precision is key in food processing, and cutters are designed to deliver just that. They slice, dice, and chop with accuracy, ensuring each piece is uniform – an essential factor for both cooking and presentation.

Blenders

Blenders are all about smoothness and homogeneity. They’re used to mix soft food items and liquids, creating everything from purees and soups to sauces. A good blender can make or break the texture of a final product.

Extruders

Extruders are the architects of the food processing world, shaping and texturizing products. They’re crucial for making pasta, cereals, snacks, and more. By forcing material through a die, extruders create foods with specific shapes and textures, expanding the possibilities of food design.

Forming Machines

Forming machines take the processed food and shape it into its final form, ready for cooking or packaging. Whether it’s forming patties, molding chocolates, or shaping cookies, these machines add the finishing touch, ensuring products are not only tasty but visually appealing.

Beth-El Machinery Ltd. Solutions

When talking about innovation and quality in food processing equipment, Beth-El Machinery Ltd. stands out. They offer a range of solutions tailored to meet the demands of modern food production. Their equipment is designed with hygiene, efficiency, and flexibility in mind, ensuring that businesses can adapt to market changes and maintain high standards of food safety.

Their equipment integrates seamlessly into existing production lines, enhancing capabilities and ensuring that your investment drives your business forward. From automated systems that reduce labor costs to machines that ensure consistent product quality, Beth-El Machinery Ltd. is at the forefront of food processing technology.

In conclusion, selecting the right processing equipment is crucial for any food production business. It’s not just about the immediate needs but also about looking ahead and preparing for future challenges and opportunities. With innovations from companies like Beth-El Machinery Ltd., businesses can stay competitive, efficient, and ready to meet the ever-changing demands of the food processing industry.

As we explore further, remember the importance of equipment that not only meets today’s standards but is also adaptable for tomorrow’s innovations.

Innovations Shaping the Food Processing Equipment Market

The food processing equipment market is rapidly evolving, driven by technological advancements that aim to increase efficiency, improve safety, and meet the changing demands of consumers. Let’s dive into how automation, the Internet of Things (IoT), robotics, and solutions from Beth-El Machinery Ltd. are revolutionizing this industry.

Automation: The Game Changer

Automation is not just a buzzword; it’s a game changer in the food processing world. It means machines can do complex tasks all by themselves, making the production process faster and reducing the chance of human error. This leads to more consistent quality and safer food products. Imagine a bakery where machines mix, knead, and bake without any manual help – that’s automation in action.

Internet of Things (IoT): Smart Processing

IoT makes machines smart. It connects equipment to the internet, allowing them to send and receive data. This can lead to better tracking of food safety, reduction in waste, and even cost savings. For example, a dairy processor could use IoT to monitor the temperature of milk at every stage, ensuring it stays fresh and safe to consume.

Robotics: Precision and Efficiency

Robotics in food processing brings precision to tasks like cutting, sorting, and packaging. Robots can work faster and more accurately than humans, and they don’t get tired. This can be especially useful in meat and poultry processing, where precise cuts are important for quality and safety.

Beth-El Machinery Ltd. Solutions: Customized Excellence

Beth-El Machinery Ltd. stands out in the food processing equipment market by offering customized solutions that integrate these innovative technologies. Their expertise in engineering and manufacturing custom processing lines, from pasteurization to product recovery systems, ensures that businesses can achieve the highest quality process systems.

For instance, their hygienic food packaging systems are designed to meet the rigorous standards of the food industry, ensuring products are safe and shelf-stable. The use of advanced automation and robotics in their equipment, such as the Hygiene Rotary Filler & Capper, allows for precise filling and capping of products, minimizing the risk of contamination and maximizing efficiency.

Beth-El Machinery’s solutions are a testament to how embracing innovations can catapult a business to the forefront of the food processing industry.

The role of technology in food processing will only grow. Companies that invest in these innovative solutions, like those offered by Beth-El Machinery Ltd., will be better equipped to face the challenges of the modern food industry. From automation to IoT and robotics, the future of food processing is here, and it’s smarter and more efficient than ever.

Selecting the Right Food Processing Equipment

Selecting the right equipment is crucial for any food processing business looking to stay competitive and efficient. Here, we’ll break down what you need to consider: Durability, Hygiene, Quality control, Customization, and the Machine Reliability Program.

Durability

The food processing environment is tough on equipment. Machines must withstand constant use, exposure to food materials, and frequent cleaning. Durability isn’t just about a machine’s lifespan; it’s about maintaining performance over time. Equipment from Beth-El Machinery Ltd. is built to last, ensuring that your investment continues to pay off year after year.

Hygiene

In the food industry, hygiene is non-negotiable. Equipment must be designed for easy cleaning and sanitization to prevent foodborne illnesses. Stainless steel is a popular choice for its resistance to corrosion and ease of cleaning. Beth-El Machinery Ltd. designs equipment with hygiene in mind, incorporating features that make thorough cleaning straightforward and effective.

Quality Control

Quality control is at the heart of food processing. The right equipment can help ensure consistency, safety, and compliance with regulations. This means looking for machines that offer precise control over processing conditions and that are reliable in every batch they produce. Beth-El Machinery Ltd. offers solutions that prioritize quality control, giving you peace of mind and a superior final product.

Customization

No two food processing operations are exactly alike. Your equipment should match your specific needs. Customization can range from adjusting machine sizes to fit your space, to tailoring functionalities for your products. Beth-El Machinery Ltd. excels in creating custom processing lines and equipment, ensuring that every client gets a solution that fits their operation perfectly.

Machine Reliability Program

Finally, the best equipment comes with support. A Machine Reliability Program ensures that your equipment keeps running smoothly, with regular maintenance and quick access to repairs and parts. This program is about more than just fixing machines; it’s about preventing downtime and optimizing performance. With Beth-El Machinery Ltd., you have a partner committed to keeping your operation running at its best.

Choosing the right food processing equipment involves considering these key factors. Durability, hygiene, quality control, customization, and a solid Machine Reliability Program are essential elements that will guide you in making the best decision for your business. With solutions from Beth-El Machinery Ltd., you can be confident that you’re investing in equipment that meets these critical needs and supports your operation’s success now and in the future.

Frequently Asked Questions about Food Processing Equipment

The food processing equipment market is evolving rapidly, driven by technological advancements and changing consumer demands. Here, we answer some of the most common questions about food processing equipment to help you stay ahead in this dynamic industry.

What are the latest trends in food processing equipment?

The food processing industry is witnessing a surge in innovative trends, aimed at enhancing efficiency, sustainability, and product quality. Here are a few standout trends:

-

Automation and Robotics: Automation is revolutionizing the food processing industry by improving production efficiency and reducing labor costs. Robotics are being increasingly adopted for tasks like sorting, packaging, and even complex operations like butchering and baking.

-

Internet of Things (IoT): IoT technology is being used to monitor equipment performance and food safety conditions in real-time, ensuring optimal operation and compliance with health standards.

-

Sustainable Solutions: With a growing focus on environmental sustainability, there is a push towards energy-efficient equipment and processes that minimize waste and water usage.

-

Customization with Beth-El Machinery Ltd.: Custom processing lines and equipment tailored to specific production needs are becoming more prevalent. Beth-El Machinery Ltd. offers bespoke solutions that cater to unique product requirements, ensuring efficiency and quality.

How does automation impact food processing efficiency?

Automation has a profound impact on food processing efficiency by:

-

Reducing Manual Labor: Automated systems can perform repetitive tasks faster and with greater precision than human workers, reducing the need for manual labor and minimizing human error.

-

Increasing Production Speed: Automation enables continuous, 24/7 production cycles, significantly increasing output.

-

Enhancing Safety: Automated systems can handle hazardous tasks, reducing workplace accidents and ensuring safer working conditions.

-

Improving Product Quality: Consistent, precise operations mean every product meets the same high standards, enhancing overall product quality.

What should businesses consider when investing in food processing equipment?

When investing in food processing equipment, businesses should keep the following considerations in mind:

-

Future-Proof Technology: Opt for equipment that can adapt to future technological advancements and changing production needs.

-

Hygiene and Safety Standards: Equipment should be easy to clean and designed to prevent contamination, complying with the highest hygiene and safety standards.

-

Reliability and Durability: Choose equipment known for its durability and reliability, like those offered by Beth-El Machinery Ltd., to ensure a long service life and minimal downtime.

-

Cost-Effectiveness: Consider not only the initial purchase price but also the long-term operational costs, including energy consumption, maintenance, and potential downtime.

-

Customization Capabilities: Ensure the equipment can be customized or adjusted to suit your specific processing needs, allowing for flexibility and scalability.

By keeping these FAQs in mind and partnering with trusted providers like Beth-El Machinery Ltd., businesses can make informed decisions that enhance their food processing capabilities, ensuring they remain competitive in the changing food processing equipment market.

Conclusion

As we look towards the future of the food processing equipment market, it’s clear that the path is paved with innovation and growth. The industry is rapidly evolving, driven by advancements in technology and an increasing demand for efficiency, safety, and sustainability in food production. Automation, the Internet of Things (IoT), and robotics continue to shape the landscape, offering unprecedented opportunities for businesses to enhance their operations.

At the heart of these advancements are solutions from Beth-El Machinery Ltd. Their state-of-the-art food processing and packaging equipment are designed to meet the highest standards of hygiene and efficiency, making them an essential part of the modern food processing plant. From highly hygienic rotary cup fillers to advanced sorting and packaging systems, Beth-El Machinery Ltd. offers solutions that cater to the diverse needs of the food industry. By integrating such innovative technologies, businesses can significantly improve their product quality, reduce waste, and ensure compliance with global food safety standards.

However, navigating the complex world of food processing equipment requires more than just selecting the right machines. It demands a comprehensive approach to machinery management and maintenance, which is where CFAB Global’s Machine Reliability Program comes into play. Our program is designed to support businesses at every step of their journey, offering expert guidance, high-quality services, and cutting-edge solutions tailored to their unique needs.

From sourcing parts and constructing bespoke equipment to providing installation services and ongoing support, our team is committed to ensuring your operations run smoothly and efficiently. Our Machine Reliability Program encompasses detailed analysis, premium services, and unparalleled support, aiming to enhance productivity, minimize equipment downtime, and extend the lifespan of critical components. By adopting our proven strategies, businesses can mitigate the risk of production delays and stay ahead in the competitive food processing equipment market.

In conclusion, the future of the food processing equipment market is bright, with endless opportunities for growth and innovation. By partnering with leaders like Beth-El Machinery Ltd. and embracing comprehensive support programs like CFAB Global’s Machine Reliability Program, businesses can navigate the complexities of the industry with confidence. Together, we can catapult your business to the forefront, ensuring you gain a competitive advantage in the changing landscape of food processing.

Discover how our solutions can transform your operations and drive your business forward. Explore our food processing equipment services and join us in shaping the future of food production.