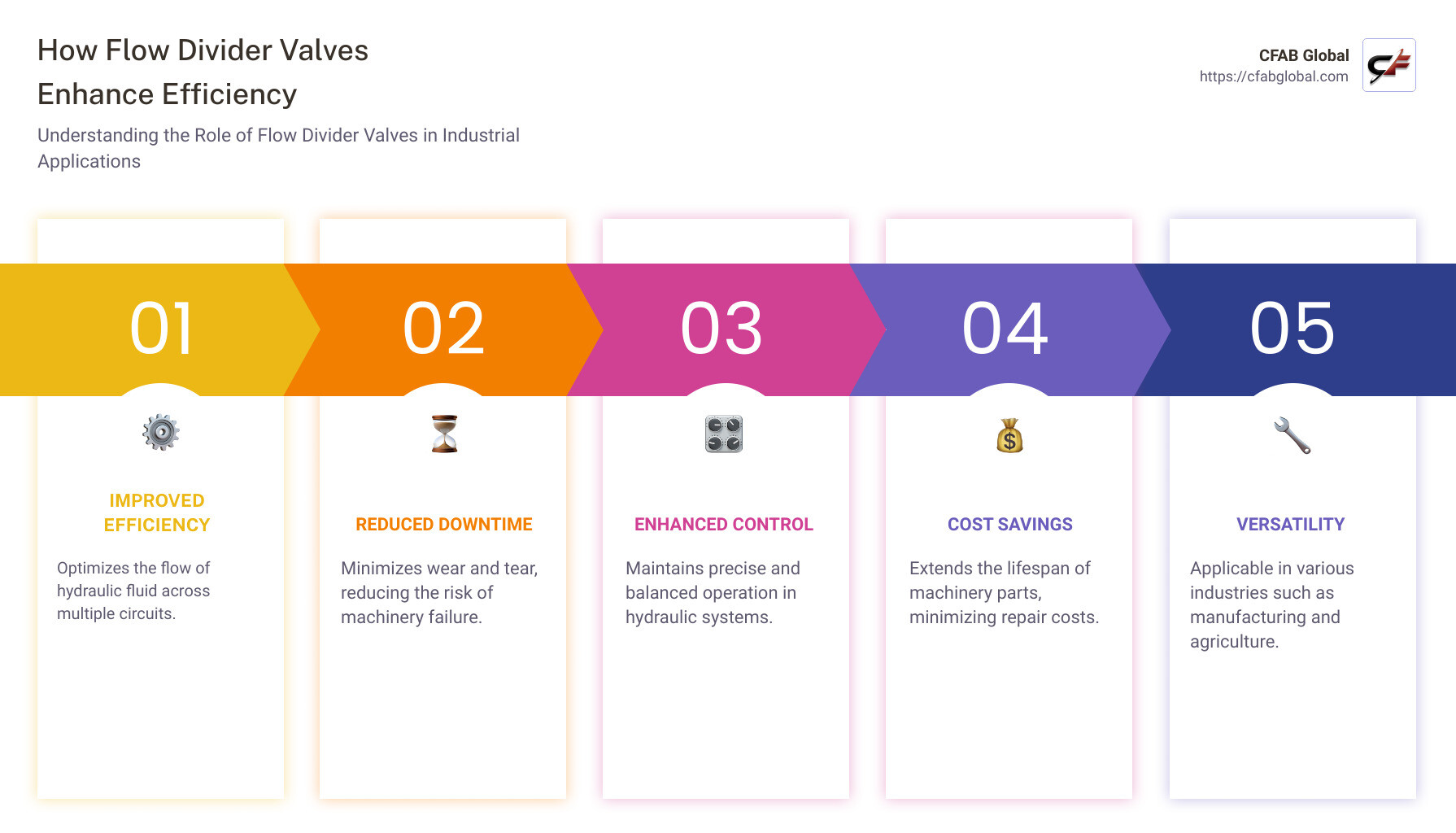

Flow divider valve is an essential component for hydraulic systems, specifically designed to regulate the flow of fluids effectively. These valves play a crucial role in various industries, ensuring that hydraulic systems operate with precision and reliability. By dividing the flow of fluid between multiple circuits, they maintain balanced and synchronized operation, enhancing the overall efficiency of machinery.

- Purpose: To split fluid flow into multiple streams evenly.

- Benefits: Improves machine efficiency and improves control.

- Applications: Used in manufacturing, construction, agriculture, and energy sectors.

In industries where machinery downtime can lead to costly delays, understanding the value of a flow divider valve can be pivotal. These valves help reduce wear and tear by providing equal flow distribution, minimizing the risk of component failure and extending the lifespan of machinery parts. This feature is particularly beneficial for companies facing frequent equipment breakdowns and looking to improve productivity through more reliable operations.

I am Todd Cleppe, CEO & Co-Founder of CFAB Global. With over 25 years of experience in improving machinery efficiency across various industries, I have seen the impact a well-chosen flow divider valve can have in minimizing downtime and reducing costs.

Terms related to flow divider valve:

– flow divider valve function

– pressure compensated flow divider

– hydraulic priority flow divider

Understanding Flow Divider Valves

Flow divider valves are vital components in hydraulic systems, designed to manage fluid flow with precision and reliability. These valves ensure that hydraulic systems operate smoothly by dividing fluid flow between multiple circuits. This balance is crucial for the synchronized operation of machinery, enhancing overall efficiency.

Types of Flow Divider Valves

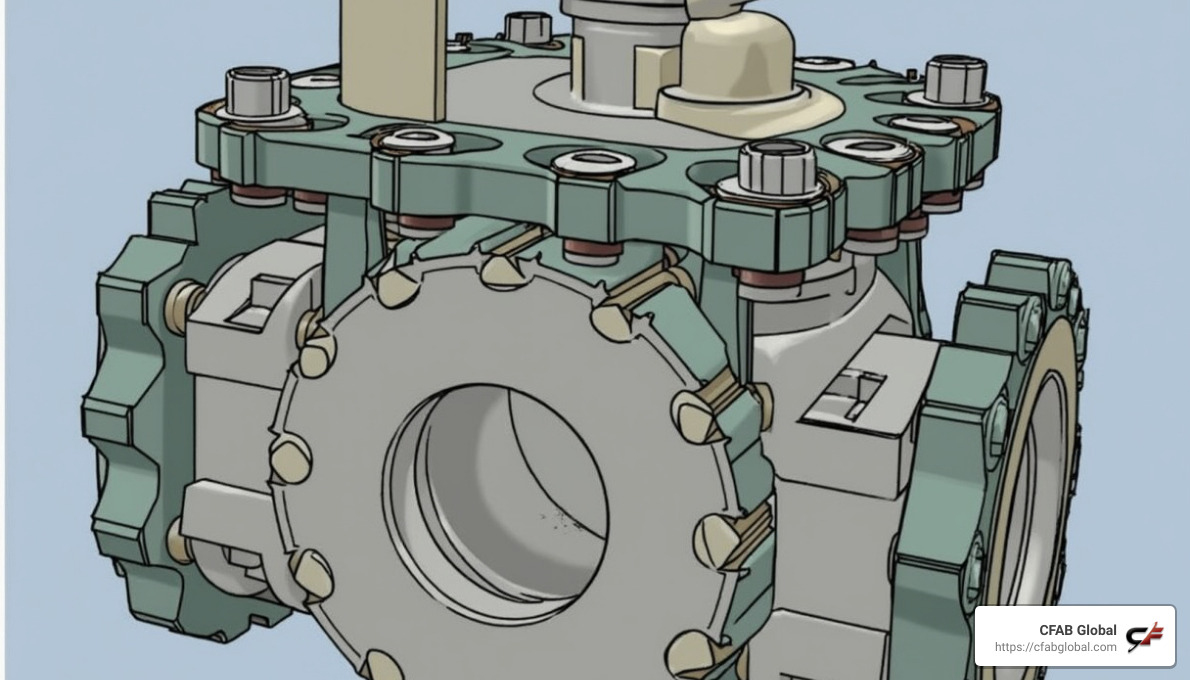

There are two main types of flow divider valves: motor type and orifice type.

-

Motor Type Flow Dividers: These use hydraulic motors to split the flow. They are ideal for applications requiring precise flow division, as they can maintain a consistent flow rate even when there are variations in load or pressure. This type is often used in systems that demand high accuracy and reliability.

-

Orifice Type Flow Dividers: These use fixed or variable orifices to divide flow. They are simpler and more cost-effective, suitable for applications where precision is less critical. However, they may struggle with maintaining equal flow under varying pressure conditions.

Key Functions of Flow Divider Valves

Flow divider valves perform two primary functions: equal flow delivery and pressure compensation.

-

Equal Flow Delivery: These valves ensure that fluid is distributed evenly between circuits. This is crucial in maintaining the balance and synchronization of hydraulic systems, preventing overloading of any single circuit.

-

Pressure Compensation: Flow divider valves adjust to changes in pressure to maintain consistent flow rates. This capability is essential for systems operating under varying loads or conditions, as it prevents pressure imbalances that could lead to inefficient operation or damage.

By understanding these types and functions, you can select the right flow divider valve for your needs, ensuring optimal performance and longevity of your machinery.

Top Flow Divider Valves on the Market

When it comes to selecting the best flow divider valves for your hydraulic systems, two standout options are Graco Inc. Flow Divider Valves and Chief Rotary Flow Dividers. Each offers unique features that cater to different industrial needs, ensuring efficient and reliable performance.

Graco Inc. Flow Divider Valves

Graco Inc. Flow Divider Valves are renowned for their precision and durability. They are designed to handle a wide range of flow rates and pressures, making them ideal for applications that require precise flow control and balancing between multiple circuits. These valves excel in scenarios where synchronized operation is crucial, such as in construction and agricultural machinery.

Graco Inc. Flow Divider Valves are built to withstand high-pressure conditions, ensuring reliability and performance in demanding environments. Their robust design makes them a top choice for industries where performance cannot be compromised.

Chief Rotary Flow Dividers

Chief Rotary Flow Dividers are well-regarded for their versatility and robust design. They come in various configurations, allowing users to handle a wide range of flow rates and pressures. These dividers are ideal for applications that require precise flow control and balancing between multiple circuits. They excel in scenarios where synchronized operation is crucial, such as in construction and agricultural machinery.

Chief Rotary Flow Dividers are designed to work under high-pressure conditions, with some models like the 0.538 CID per section offering a flow range of 1.7-7 GPM per section. This makes them suitable for demanding environments where reliability and performance cannot be compromised.

Both Graco Inc. and Chief offer reliable solutions for managing hydraulic flow, ensuring your machinery operates efficiently and effectively. Selecting the right flow divider valve from these top options will depend on your specific requirements, such as flow rate, pressure rating, and the complexity of your hydraulic system.

How to Choose the Right Flow Divider Valve

Choosing the right flow divider valve is crucial for ensuring your hydraulic system operates smoothly and efficiently. Here are some key factors to consider:

Flow Rate

Flow rate is the amount of fluid that passes through the valve per unit of time, typically measured in gallons per minute (GPM). It’s important to select a valve that matches the flow requirements of your system. For example, Chief Rotary Flow Dividers offer models with flow ranges like 1.7-7 GPM per section, which can be ideal for specific applications like construction or agricultural machinery where precise flow control is needed.

Pressure Rating

Pressure rating indicates the maximum pressure a valve can handle safely. This is crucial for maintaining system integrity and avoiding leaks or failures. For instance, Hydraforce Flow Divider/Combiner units can handle pressures up to 5000 PSI, making them suitable for high-pressure environments such as energy or manufacturing sectors. Ensure your chosen valve can withstand the pressures of your application to ensure long-term reliability.

Port Size

Port size affects how the valve connects to other components in the system. This can influence both installation and performance. Common port sizes include SAE and NPT standards, with options like 3/8″ NPT or #10 SAE ports available in various models. The right port size will ensure compatibility with your existing system and facilitate efficient fluid movement.

Considerations for Specific Industries

-

Manufacturing: In manufacturing, consistency and reliability are key. A flow divider valve like the Hydraforce unit, capable of handling high pressures and providing dual functionality, can improve productivity by ensuring smooth operations in complex hydraulic systems.

-

Construction: Construction equipment often requires robust and precise flow control due to the heavy-duty nature of the work. Chief Rotary Flow Dividers are a great fit here, offering configurations that support synchronized operations and high-pressure conditions.

-

Agriculture: Agricultural machinery benefits from flow dividers that provide equal flow delivery to multiple circuits. This ensures that all parts of the machinery work in harmony, improving efficiency and reducing wear and tear.

-

Energy: The energy sector demands valves that can withstand extreme conditions. High-pressure ratings and durable designs, like those found in Hydraforce units, are essential for maintaining safety and performance in energy applications.

By carefully considering these factors—flow rate, pressure rating, port size, and industry-specific needs—you can select the perfect flow divider valve for your hydraulic system. This will not only improve performance but also extend the lifespan of your equipment.

Frequently Asked Questions about Flow Divider Valves

What is a flow divider valve?

A flow divider valve is a crucial component in hydraulic systems. Its primary role is to split the flow of fluid into two or more paths, ensuring that each path receives an equal or proportional amount of fluid. This is essential for applications where synchronized movement or balanced load distribution is critical. Whether you’re working with agricultural machinery or industrial equipment, these valves help maintain consistent performance across various components.

What is the purpose of a flow diverter valve?

A flow diverter valve is designed to manage the direction of media flow within a system. Unlike a flow divider, which splits the flow, a diverter valve redirects the flow from one path to another. This capability is particularly useful in systems that require alternate flow paths, such as in manufacturing processes or automated lubrication systems where specific components need lubrication at different times. By managing media flow efficiently, these valves help optimize operational efficiency and reduce wear and tear on equipment.

What are the two primary functions of the flow divider?

The two primary functions of a flow divider are flow splitting and pressure compensation.

-

Flow Splitting: This function ensures that the hydraulic fluid is divided evenly between multiple circuits. It’s essential for applications where equal power distribution is necessary, such as in multi-cylinder machinery or synchronized operations in construction equipment. By delivering consistent flow, the valve helps maintain balanced movement and reduces the risk of component failure.

-

Pressure Compensation: This feature allows the valve to adjust for variations in pressure, ensuring that each circuit receives the correct flow rate regardless of load changes. This is particularly important in systems where different components may experience varying levels of resistance. Pressure compensation helps prevent system overloads and maintains smooth operation, enhancing the overall reliability of the hydraulic system.

Understanding these functions can help you choose the right flow divider valve for your specific needs, ensuring optimal performance and longevity of your hydraulic equipment.

Conclusion

At CFAB Global, we understand the critical role that flow divider valves play in ensuring the efficiency and reliability of hydraulic systems. Our dedication to providing top-tier machinery solutions is exemplified through our exclusive Machine Reliability Program. This program is designed to improve the performance and lifespan of your machinery, minimizing downtime and maximizing productivity.

Why Choose CFAB Global?

Our expertise spans across industries such as manufacturing, construction, agriculture, and energy. We tailor our solutions to meet the unique demands of each sector, ensuring that your equipment operates at peak efficiency.

-

Customized Solutions: We don’t believe in one-size-fits-all. Our Machine Reliability Program is customized to your specific needs, offering a strategic approach to maintenance and performance optimization.

-

Proactive Maintenance: Our focus on predictive maintenance strategies helps prevent breakdowns before they occur, saving you time and money.

-

Increased ROI: By reducing downtime and extending the lifespan of your machinery, we help your business maximize its return on investment.

For businesses seeking reliable machinery solutions, CFAB Global is your trusted partner. Our commitment to excellence and client success ensures that your operations run smoothly and efficiently.

Explore how our services can transform your machinery management by visiting our Machine Reliability Program.

Experience the CFAB Global difference—where expert solutions meet unparalleled support.