When you’re searching for dry food packaging equipment, you’re likely looking to understand the essential machinery involved in the packaging process of dry food products. Right away, you want to know what types of machines exist, their applications, and how they can benefit your production line. Here’s a brief overview:

- Filling Machines: For accurately dispensing dry food into packaging.

- Weighing Machines: Ensuring each package has the correct amount of product.

- Sealing Machines: To securely close packages and maintain product freshness.

- Labeling Machines: For adding necessary product information and branding.

- Container Unscrambling Machines: To organize containers for filling efficiently.

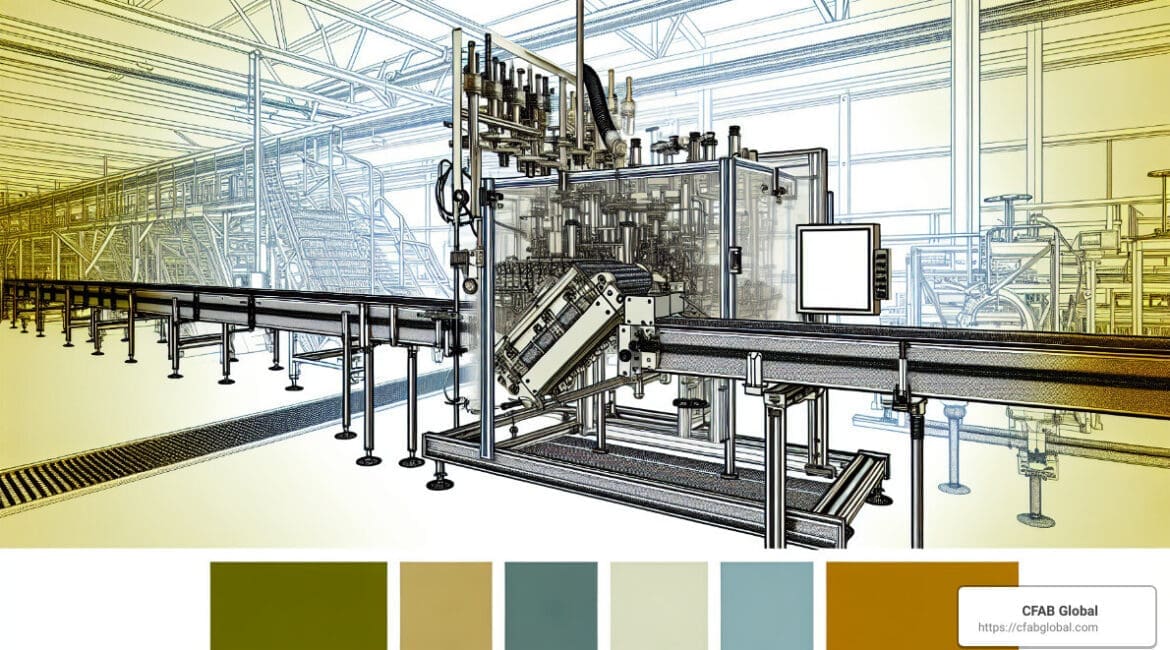

At CFAB Global, we emphasize solutions from Beth-El Machinery Ltd., renowned for their hygienic food packaging systems. Their equipment is designed to enhance productivity, reduce downtime, and support a range of dry food packaging needs.

If you’re diving into dry food packaging, understanding the basics of what equipment is needed and how it fits together is key. This guide is destined to provide insight into selecting the right machinery that aligns with your needs, highlighting versatility, efficiency, and how these solutions can address your pain points such as lost-time production and the need for tailored solutions.

In the simplest terms, no matter the scale of your operation, from startup to full-scale commercial production, having a grasp on the essential dry food packaging equipment is fundamental to streamlining your operations and ensuring product quality. Let’s delve further into detailed types of dry food packaging equipment and the advanced technologies that can revolutionize your packaging lines.

Types of Dry Food Packaging Equipment

In dry food packaging, the variety of equipment available can be overwhelming. Each type of machine has its unique role in ensuring your products are packaged efficiently, safely, and attractively. Here’s a breakdown of the essential dry food packaging equipment you need to know about:

Batching Machines

Batching machines are the unsung heroes of the packaging world. They precisely measure out the product before it’s packaged, ensuring that each package contains the correct amount of product. This is crucial for maintaining consistency and customer trust.

Bagging Machines

Bagging machines take the measured product and neatly pack it into bags. They can handle a variety of bag sizes and materials, from paper to foil to plastic. Some advanced machines can even vacuum seal the bags, extending the shelf life of the product.

Sleeving Machines

Sleeving machines add an extra layer of protection and branding to your product by sliding a sleeve over the container. This is often used for products like ice cream tubs or drink bottles, providing both tamper evidence and an attractive presentation.

Box Making Machines

Box making machines are essential for businesses that package their products in cardboard boxes. These machines can quickly assemble boxes in various sizes, ready to be filled with your product. Some models also print branding or nutritional information directly onto the box.

Bundling Machines

Bundling machines are used to group multiple packages together for easier shipping and handling. Whether it’s wrapping several packages with plastic or tying them with a band, these machines make it easy to create multi-packs of your product.

Capping Machines

Capping machines securely seal the product container, whether it’s screwing on a cap, pressing on a lid, or crimping a seal. This step is crucial for preventing leaks and ensuring the product remains fresh until it reaches the consumer.

Carton Machines

Carton machines take flat carton blanks and erect them into boxes, ready to be filled with product. These machines can handle a wide range of carton sizes and styles, making them a versatile choice for many types of dry food products.

By integrating these types of dry food packaging equipment into your production line, you can streamline your operations, reduce labor costs, and ensure your products are packaged in a way that meets your standards for quality and presentation. The right equipment can make a significant difference in the efficiency and profitability of your packaging operations.

We’ll explore the key processes in dry food packaging, shedding light on how each step contributes to the final product’s quality and appeal. This will include a closer look at filling machines, inspecting equipment, labeling and printing solutions, and more, ensuring you have a comprehensive understanding of what it takes to package dry foods effectively.

Key Processes in Dry Food Packaging

When it comes to dry food packaging, several key processes ensure the product reaches the consumer in the best possible condition. Let’s dive into the essential steps involved, from filling to unscrambling, and understand how each plays a crucial role in the packaging journey.

Filling Machines

Filling machines are the heroes of the packaging world. They handle dry, powdered, solid, liquid, gas, and viscous products. Whether it’s milk powder, coffee, or spices, these machines ensure that the right amount of product goes into each package. They work with precision, so every bag, box, or bottle has the exact quantity required. This accuracy is vital for maintaining product quality and customer trust.

Inspecting Equipment

Once the product is in its package, it’s crucial to make sure everything is up to standard. That’s where inspecting equipment comes in. These machines use visual and sound checks, and even metal detecting to ensure there are no foreign objects in the food. They can spot anything that shouldn’t be there, keeping the food safe for consumption. This step is crucial for maintaining high-quality standards and avoiding recalls.

Labeling and Printing Solutions

Now, imagine picking up two packages of the same product, but you can’t tell them apart because they’re missing labels. That’s a scenario no company wants. Labeling and printing solutions are vital for providing consumers with the information they need. From ingredients and nutritional information to expiry dates, label dispensers and printers make sure every package is correctly marked. This transparency builds trust with consumers and complies with food safety regulations.

Sealing

Sealing is the final guardian of food safety and freshness. It keeps the product safe from contamination and ensures it stays fresh until it reaches the consumer. Whether it’s a heat sealer for bags or a capper for bottles, the right sealing process is crucial. It’s the seal that stands between the food and external factors that could compromise its quality.

Weighing

Accuracy is key in packaging, and that’s where weighing comes in. This process ensures that each package contains the right amount of product. It’s a balance between generosity and cost-efficiency, making sure customers get what they pay for without giving away too much. Weighing machines, like checkweighers, are an essential part of this process, ensuring each product meets its specified weight.

Unscrambling

Before anything can be filled, labeled, or sealed, the containers themselves need to be in order. That’s the job of unscrambling machines. They take bottles, jars, or boxes that are jumbled up and align them correctly for the packaging process. This step might seem small, but it’s vital for keeping the packaging line moving smoothly and efficiently.

In conclusion, each step in the dry food packaging process plays a crucial role in ensuring the product reaches the consumer in perfect condition. From the precision of filling machines to the protective seal, and the informative label, every step is designed to maintain quality, safety, and consumer trust. With advancements in technology, these processes continue to become more efficient and effective, ensuring that dry food packaging meets the high standards expected by consumers and regulators alike.

Innovations in Dry Food Packaging Technology

The world of dry food packaging is constantly evolving, with new technologies making the process faster, more efficient, and safer. Let’s dive into some of the innovations that are changing the game.

Powder Filling Machine Operation

Airjet Cleaners

One of the first steps in ensuring the quality of packaged dry food products is keeping the packaging equipment clean. Airjet cleaners are a standout innovation in this area. They use high-pressure air to remove dust and other contaminants from containers before filling. This step is crucial for maintaining hygiene standards and ensuring that the final product is free from any unwanted particles.

Vertical Form Fill and Seal Bagging Machines

Vertical Form Fill and Seal (VFFS) Bagging Machines have revolutionized packaging. They are a one-stop solution that forms the bag from a roll of film, fills it with the product, and then seals it. This method is not only efficient but also reduces waste by adjusting the bag size to fit the product perfectly. VFFS machines are versatile and can handle a wide range of dry food products, from grains and powders to snacks.

Checkweighing Machines

Accuracy is key in packaging. Checkweighing machines ensure that each package contains the exact amount of product specified. These machines weigh the filled packages and reject any that fall outside of the set weight range. This step is vital for quality control, customer satisfaction, and minimizing waste.

Container Unscrambling Machines

For businesses that use bottles or jars, container unscrambling machines streamline the packaging process. These machines automatically sort and organize containers onto the production line, ready for filling. This automation saves time and reduces the need for manual labor, allowing for a more efficient production process.

The Process

Conveyor Systems

Conveyor systems are the backbone of any packaging line. They transport products smoothly from one stage of the packaging process to the next. Innovations in conveyor technology have made them more adaptable and efficient, capable of handling a wide variety of products and packaging types.

Filling Head

The filling head is where the product is dispensed into the packaging. Modern filling heads are designed to handle a range of dry food products with precision. They can be easily adjusted to accommodate different fill volumes and are often equipped with technology to minimize product waste.

Product Measurement

Accurate product measurement is crucial for consistent packaging. Advanced sensors and measurement devices ensure that the exact amount of product is dispensed every time. This technology not only improves accuracy but also helps in maintaining the consistency of the packaged product.

These innovations in dry food packaging technology are making the process more efficient, accurate, and hygienic. As technology continues to advance, we can expect even more improvements in the packaging process, benefiting both businesses and consumers.

The next section will delve into the most frequently asked questions about dry food packaging equipment, providing you with deeper insights into this essential industry tool.

Frequently Asked Questions about Dry Food Packaging Equipment

Navigating dry food packaging equipment can be complex. Here, we address some of the most common questions to help simplify this essential industry tool.

What Equipment is Used for Packaging?

In the realm of dry food packaging, a variety of machines are employed to ensure products are packaged efficiently and safely. This includes:

- Batching Machines: These prepare the product for packaging by ensuring the correct amount is ready for each package.

- Bagging Machines: Essential for packing dry foods into bags, ensuring they’re sealed correctly to maintain freshness.

- Sleeving Machines: These add a protective sleeve around the product or its container for additional safety and branding.

- Box Making Machines: For products that require boxing, these machines fold and shape boxes to the right dimensions.

- Bundling Machines: Used for grouping products together, making them easier to ship and display.

- Capping Machines: Essential for products that come in bottles or jars, ensuring they’re tightly sealed.

- Carton Machines: Similar to box making, but specifically designed for folding and filling cartons.

Each piece of equipment plays a vital role in the packaging process, ensuring products are ready for the shelf.

How Does a Powder Filling Machine Work?

Powder filling machines are fascinating in their operation. Here’s a simplified breakdown:

- Product Measurement: First, the exact amount of product needed for each package is measured, often using auger fillers for precision.

- Conveyor System: The product is then transported to the filling station via a conveyor belt.

- Filling Head: At the filling station, a filling head releases the measured product into the package. This step is carefully controlled to avoid spills and ensure accuracy.

- Sealing: Once filled, the package is sealed to keep the product fresh and prevent contamination.

The process is highly automated, ensuring efficiency and accuracy in packaging dry food products.

How Many Types of Packaging Machines Are There?

The world of packaging machines is vast, with equipment designed to handle all aspects of the packaging process. Broadly speaking, packaging machines can be categorized into:

- Filling Machines: For adding product to containers.

- Sealing Machines: To seal the product containers after filling.

- Labeling Machines: For adding labels to the product packaging.

- Wrapping Machines: Used to wrap products or containers for protection and branding.

- Cleaning Machines: Such as airjet cleaners, ensure containers are clean before filling.

Additionally, there are specialized machines like vertical form fill and seal bagging machines, checkweighing machines, and container unscrambling machines, each designed to streamline specific parts of the packaging process.

The choice of machine depends on the specific needs of the product being packaged, including its size, shape, and the type of packaging material being used. With advancements in technology, these machines are becoming ever more efficient, accurate, and hygienic, making the packaging process smoother and more reliable.

As we continue to explore the intricacies of dry food packaging equipment, it’s clear that the right machinery can significantly impact a business’s efficiency and product quality. Whether you’re new to the industry or looking to upgrade your operations, understanding these key pieces of equipment is essential.

Conclusion

After delving deep into dry food packaging equipment, it’s evident how crucial the right machinery is for enhancing operational efficiency and ensuring the quality of products. At CFAB Global, we understand that every piece of equipment plays a vital role in the packaging process, from filling and inspecting to labeling and sealing. But beyond the machines themselves, what truly sets us apart is our commitment to ensuring these machines continue to operate at their peak performance throughout their lifecycle. This is where our Machine Reliability Program comes into play.

Our Machine Reliability Program is designed to support you long after the initial purchase. We’re not just about selling you a piece of equipment; we’re about ensuring that it continues to meet your needs, day in and day out. This program encompasses a comprehensive suite of services that include regular maintenance checks, real-time monitoring to predict and prevent potential issues, and rapid response support for any unexpected problems. Our goal is to minimize downtime and maximize productivity, ensuring that your operations run as smoothly as possible.

At CFAB Global, our dedication to your success doesn’t end with the sale. We pride ourselves on being partners in your journey, providing not just the tools you need, but the ongoing support that makes all the difference. Our team of experts is always ready to assist, whether it’s helping you choose the right equipment for your needs or offering advice on how to optimize your existing setup.

In a constantly evolving industry, staying ahead means not just keeping up with the latest innovations in dry food packaging technology, but also ensuring that your equipment is always in top condition. That’s why we invite you to explore our range of services and see for yourself how our Machine Reliability Program can benefit your business.

For more information on how we can help you improve your dry food packaging process, visit our food packaging machines page. Together, let’s ensure your packaging operations are as efficient, reliable, and productive as possible.

At CFAB Global, we’re committed to your success. Our success is measured by your ability to meet and exceed your production goals, ensuring that you can deliver quality products to your customers without delay. Let us be your partner in achieving operational excellence.