Introduction

The difference between oil and grease lubrication is crucial for keeping your machinery running smoothly and efficiently. Here’s a quick breakdown:

- Composition: Oil is a liquid lubricant, while grease is oil mixed with a thickener, resulting in a semi-solid form.

- Consistency: Oil has a low viscosity, making it suitable for high-speed applications; grease is thicker and carries additives for long-lasting protection.

- Applications: Oil is ideal for high-speed machinery due to better cooling properties. Grease is better for sealing against contaminants and is easier to apply in industrial settings.

Understanding the basics of these lubricants can help you make the best choice for your equipment.

Hi, I’m Todd Cleppe. With over 25 years of experience in designing and improving lubrication systems across various industries, I’ve seen the impact of selecting the right lubricant. My expertise lies in engineering efficient, reliable solutions for machinery, ensuring the longevity and productivity of your investments.

Understanding Lubrication Basics

Lubrication is essential for keeping machinery running smoothly. It reduces friction, minimizes wear, and protects against metal-on-metal contact. Here’s a simple breakdown of how lubrication works and why it’s so important.

Lubrication Function

At its core, lubrication aims to create a protective film between moving parts. This film reduces friction, which in turn lowers the heat generated by machinery. Less friction means parts last longer and machines run more efficiently.

Imagine two metal gears grinding against each other. Without lubrication, the friction would cause them to wear down quickly, leading to equipment failure. Lubricants like oil and grease prevent this by creating a slippery barrier between the gears.

Metal-on-Metal Contact

Metal-on-metal contact is the enemy of machinery. When metal parts rub against each other without lubrication, they generate heat and wear. This can lead to costly repairs and downtime. Lubricants act as a buffer, preventing direct contact and reducing the damage caused by friction.

For example, in a car engine, oil flows through the engine parts, creating a film that keeps the metal components from grinding against each other. This not only extends the life of the engine but also improves its performance.

Wear Protection

Wear protection is another critical function of lubrication. Over time, even the best-machined parts can wear down due to constant use. Lubricants help to slow this process by reducing the friction and heat that contribute to wear.

Grease, for instance, is often used in high-load applications where parts are subject to heavy pressure. It stays in place longer than oil, providing consistent protection against wear. This makes it ideal for machinery that operates under extreme conditions.

In summary, understanding the basics of lubrication—its function, the importance of preventing metal-on-metal contact, and its role in wear protection—can help you make informed decisions about the best lubricant for your machinery.

Next, let’s dive into the difference between oil and grease lubrication to further guide your choices.

Difference Between Oil and Grease Lubrication

To make an informed choice about lubricants, understand the difference between oil and grease lubrication. Both aim to reduce friction and wear, but they have distinct properties and applications.

What is Oil Lubrication?

Oil lubrication involves using a liquid lubricant. Oils are typically made from refined petroleum, synthetic compounds, or a blend of both. They are fluid at room temperature, which allows them to flow easily and coat surfaces effectively.

Composition: Oils consist of base oil and various additives that enhance properties like viscosity, oxidation resistance, and anti-wear capabilities.

Consistency: Oils are less viscous than greases, making them more fluid and easier to pump and distribute.

Applications: Oil is ideal for high-speed applications where heat dissipation is crucial. For instance, in car engines, oil circulates to lubricate moving parts and carry away heat. The fluid nature of oil ensures it reaches tight spaces and provides continuous lubrication.

Cooling Properties: One significant advantage of oil is its ability to transfer heat. By circulating through the system, oil absorbs heat from components and dissipates it, preventing overheating.

High-Speed Applications: Oil is preferred in environments where components move rapidly. For example, in a jet engine, oil is essential for lubricating fast-moving parts and keeping them cool.

What is Grease Lubrication?

Grease lubrication uses a semi-solid lubricant composed of oil mixed with a thickener, often a soap-like substance. This mixture gives grease its unique properties.

Composition: Grease is essentially oil held in place by a thickener. It may also contain additives for enhanced performance, like anti-corrosion agents.

Consistency: The consistency of grease is measured by NLGI grades. The higher the grade, the thicker the grease. This thickness allows grease to stay in place longer than oil.

Applications: Grease is perfect for situations where you need long-lasting lubrication and protection from contaminants. It’s commonly used in bearings, gears, and other components that are hard to reach or require infrequent lubrication.

Sealing Capabilities: Grease forms a barrier against contaminants like dust and water, making it ideal for harsh environments.

Semi-Solid Nature: Because grease is thicker, it doesn’t flow away from the application point. This makes it suitable for parts that operate intermittently or are subject to high pressure, such as in heavy machinery.

In summary, the choice between oil and grease depends on the specific needs of your machinery. Oil is excellent for high-speed, high-heat applications, while grease is better for sealing and long-lasting lubrication in challenging environments.

When to Use Oil Over Grease

Choosing between oil and grease lubrication can feel tricky, but it boils down to understanding your machinery’s specific needs. Let’s dive into when oil lubrication is the better choice.

High Speed

Oil is the go-to option for high-speed applications. Think about the fast-moving parts in an engine or a high-speed gearbox. Oil flows easily and can be continuously circulated, ensuring that all moving components are well-lubricated. This is crucial in high-speed environments where friction can quickly lead to wear and tear.

Heat Dissipation

One of the standout features of oil is its ability to dissipate heat. In high-temperature settings, such as engines or industrial machines, oil acts as both a lubricant and a coolant. It transfers heat away from the components, preventing overheating and potential damage.

Imagine a car engine running at full speed; oil not only reduces friction but also helps keep the engine cool. This is something grease simply can’t do as effectively due to its thicker, semi-solid nature.

Easy Application

Oil is easier to apply than grease, especially in complex machinery with tight spaces. It can be pumped or sprayed, ensuring that even the smallest and hardest-to-reach components get lubricated. For instance, gun owners often use oil to lubricate their firearms because it penetrates better into the metal pores and doesn’t make a mess like grease.

In summary, oil is your best bet for high-speed, high-heat applications, and when you need an easy-to-apply solution. It keeps your machinery running smoothly and cool, ensuring longer life and better performance.

Next, let’s explore when grease is the better option.

When to Use Grease Over Oil

Grease is not just thickened oil. It’s a powerful lubricant with unique advantages. Here are the key scenarios where grease outshines oil:

Leakage Control

Grease is excellent for preventing leaks. Its semi-solid form stays put, unlike oil which can easily drip away. This makes grease ideal for applications where leakage is a concern. For example, in heavy machinery, grease helps keep everything in place, reducing the risk of lubricant escaping and causing damage.

Contaminant Sealing

Grease acts as a barrier against contaminants. It seals out dirt, water, and other particles that could harm your machinery. This is especially important in high-contaminant environments like construction sites or food processing plants.

Quote: “Grease can remain in equipment longer and tolerate a variety of conditions,” explains a Reddit user. This makes it perfect for gearboxes, bearings, and joints exposed to harsh conditions.

Long-Lasting Application

Grease lasts longer than oil. It doesn’t need to be replaced as frequently, which means less maintenance and downtime. This is crucial for machinery that operates intermittently or under extreme conditions. Grease stays in place, providing continuous lubrication and protection.

Summary

To sum up, choose grease over oil when you need:

- Leakage control: Keeps lubricant in and contaminants out.

- Contaminant sealing: Protects machinery from dirt, water, and particles.

- Long-lasting application: Reduces maintenance and downtime.

Selecting the Right Lubricant for Your Machinery

Choosing the right lubricant can make a huge difference in the performance and longevity of your machinery. Here are key factors to consider:

NLGI Grades

The National Lubricating Grease Institute (NLGI) grades help you determine the consistency of grease. The grades range from 000 (fluid) to 6 (block). For most applications, grades 1 to 3 are common.

- Grade 1: Soft and suitable for low temperatures.

- Grade 2: Medium consistency, ideal for general-purpose use.

- Grade 3: Thick, used in high-temperature or high-load conditions.

Load Carrying Ability

The load carrying ability of a lubricant is crucial, especially for heavy machinery. Greases with Extreme Pressure (EP) additives are designed for high-load applications. They form a protective layer that prevents metal-to-metal contact even under extreme pressure.

Fact: EP greases often contain additives like molybdenum disulfide or graphite, which provide extra protection under high loads.

Compatibility

Not all lubricants are compatible. Mixing incompatible greases can lead to a breakdown in their properties, causing ineffective lubrication and potential damage. Always consult a miscibility chart to ensure that the lubricants you are using can work together.

Tip: Test a small mix of the greases and let it stand. If it doesn’t separate, it’s likely compatible.

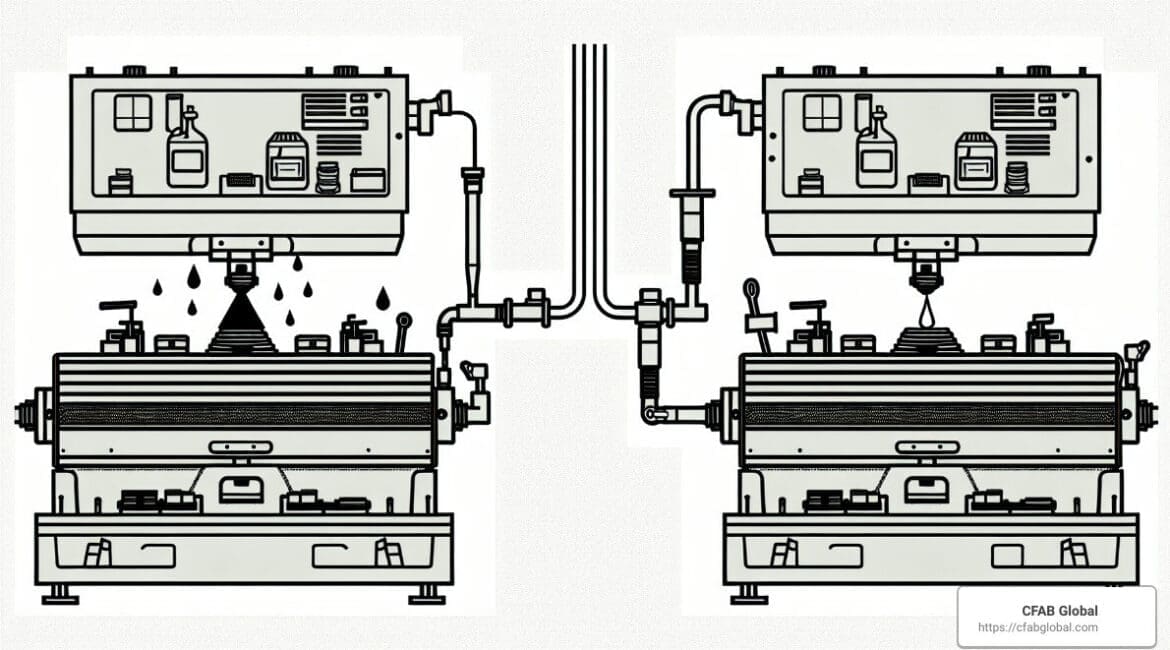

CFAB Global’s Machine Reliability Program

At CFAB Global, we understand the critical role lubrication plays in machinery performance. Our Machine Reliability Program offers a comprehensive approach to maintenance. This includes:

- Detailed Analysis: We assess your machinery’s lubrication needs.

- Premium Services: From sourcing the right lubricants to application techniques.

- Cutting-edge Equipment: Ensuring optimal lubrication and minimal downtime.

- Unparalleled Support: 24/7 assistance to keep your operations running smoothly.

By following these guidelines and leveraging our expertise, you can maximize your machinery’s efficiency and lifespan.

Frequently Asked Questions about Lubrication

Can you mix different greases?

In general, it’s not advisable to mix different greases. The term for mixing greases is miscibility. When greases are not compatible, they can lose their beneficial properties, such as thickening or lubrication. For instance, mixing a lithium-based grease with a calcium-based grease might result in a mixture that fails to lubricate effectively. Always check a miscibility chart before mixing greases to ensure compatibility.

How often should you replace grease in machinery?

The frequency of grease replacement depends on several factors, including the type of machinery, operating conditions, and the type of grease used. A good rule of thumb is to follow the manufacturer’s recommendations found in the equipment’s manual. For example, machinery operating in extreme wet or heavily loaded conditions may require more frequent greasing. Regular inspections can also help determine when fresh grease is needed, especially in high-contaminant environments.

What are the signs of inadequate lubrication?

Inadequate lubrication can lead to several issues, including:

- Increased Noise: Unusual squeaking or grinding sounds can indicate a lack of lubrication.

- Overheating: Excessive heat generation can be a sign that the lubricant is not effectively reducing friction.

- Wear and Tear: Visible signs of wear on metal surfaces suggest that the lubricant is not providing adequate protection.

- Leakage: Oil or grease leaking from machinery can indicate that the lubricant is not staying in place.

Regular maintenance and using high-quality lubricants can help avoid these problems. For food packaging or food processing solutions, consider using Beth-El Machinery Ltd. for reliable and efficient equipment solutions.

Next, let’s explore how to select the right lubricant for your machinery.

Conclusion

Choosing the right lubricant—whether oil or grease—is crucial for the longevity and efficiency of your machinery. Oil is ideal for high-speed applications and heat dissipation, while grease excels in leakage control, contaminant sealing, and long-lasting applications.

Recap

- Oil Lubrication: Best for high-speed machinery, easy application, and excellent cooling properties.

- Grease Lubrication: Ideal for preventing leakage, sealing contaminants, and providing durable lubrication in extreme conditions.

Best Practices

- Assess Your Application: Consider factors like speed, temperature, and environmental conditions.

- Check Compatibility: Ensure the lubricant is compatible with your machinery’s seals and materials.

- Regular Maintenance: Regularly check and replace lubricants to avoid wear and tear.

At CFAB Global, we offer a comprehensive Machine Reliability Program to help you choose the right lubricant and maintain your equipment efficiently. Our solutions are designed to minimize downtime, extend machinery lifespan, and enhance productivity.

For food packaging or food processing solutions, we recommend Beth-El Machinery Ltd. Their reliable equipment ensures your operations run smoothly and efficiently.

By following these guidelines and leveraging our expertise, you can ensure your machinery operates at peak performance, reducing the risk of costly breakdowns and extending the life of your equipment.

For more information on selecting the right lubricant for your machinery, visit our Automated Lubrication System page.