Custom packaging machinery is revolutionizing business operations by enhancing efficiency and seamlessly integrating automation into production lines. In today’s competitive market, companies face constant pressure to deliver high-quality products swiftly and cost-effectively. Custom packaging machinery addresses these challenges by offering tailored solutions that improve operational efficiency and streamline processes. This machinery is becoming essential in industries like food, pharmaceuticals, and electronics due to its adaptability and precision. For instance, when discussing food packaging solutions, it’s crucial to highlight BE Machinery’s offerings, such as the Hygiene Rotary Filler & Capper and Bottles Sterilization Machine, which are designed to meet specific industry needs.

- Efficiency & Cost Savings: Boosts production speed and reduces labor costs.

- Streamlined Processes: Automates repetitive tasks, minimizing errors.

- Flexibility: Custom-designed to meet unique business needs.

I’m Todd Cleppe, an industry expert in custom packaging machinery with over 25 years across sectors like food packaging and industrial mining. My journey began with developing innovations in machinery engineering, leading to successful operational improvements and long-standing client relationships.

Understanding Custom Packaging Machinery

Custom packaging machinery is a game-changer for businesses across various industries. It combines customization, flexibility, and integration to create solutions tailored to specific operational needs. Let’s explore the benefits and key features that make custom packaging machinery essential for modern production.

Benefits of Custom Packaging Machinery

1. Efficiency & Cost Savings

Custom packaging machinery significantly boosts efficiency. By automating repetitive tasks, it reduces the need for manual labor, leading to substantial cost savings. Imagine a production line where machines handle packaging with precision and speed, cutting down on errors and waste. This is the promise of custom machinery—streamlined operations that save both time and money.

2. Scalability

As your business grows, your packaging needs may change. Custom packaging machinery offers the scalability to adapt to these changes. Whether you need to increase production volumes or introduce new packaging styles, customized solutions can expand alongside your business.

3. Improved Product Quality

With custom machinery, you gain control over the packaging process, ensuring consistency and quality. This is crucial for industries like food and pharmaceuticals, where compliance and safety standards are non-negotiable.

Key Features to Look For

1. Automation

Automation is at the heart of custom packaging machinery. It eliminates human error and increases production speed. Look for machinery that integrates seamlessly with existing systems, ensuring minimal disruption and maximum efficiency.

2. Adaptability

Adaptability means your machinery can handle different packaging types and sizes. This flexibility is vital for businesses that deal with a variety of products.

3. Precision

Precision in packaging ensures that every product is handled with care and accuracy. This is particularly important in the electronics and pharmaceutical industries, where even minor errors can lead to significant issues. Custom machinery with precise control features guarantees that your products are packaged to perfection every time.

4. Integration

Integration capabilities allow custom packaging machinery to work harmoniously with existing production lines. This ensures a smooth transition and minimal downtime during implementation.

Types of Custom Packaging Machinery

Custom packaging machinery comes in various forms, each designed to meet the specific needs of different industries. Whether it’s robotic systems for precision, automated lines for efficiency, or specialized equipment for unique industry requirements, there’s a solution for every business.

Robotic Packaging Systems

Robotic packaging systems are all about precision, speed, and versatility. These systems use advanced robotics to handle tasks with incredible accuracy. Imagine a robot arm swiftly packaging delicate electronics or pharmaceuticals, ensuring each item is handled with care. This level of precision is crucial in industries where even the slightest error can lead to costly mistakes.

Robotic systems can also adapt to different packaging formats and sizes, making them a versatile choice for businesses with diverse product lines.

Automated Packaging Lines

Automated packaging lines focus on efficiency, consistency, and productivity. These lines integrate various machines to create a seamless flow from product preparation to final packaging. Think of an assembly line where each step is automated, from filling and sealing to labeling and boxing.

This automation ensures that products are packaged quickly and consistently, reducing manual labor and minimizing errors. For example, the Box Folding Line from BE Machinery provides a flexible solution for handling a wide variety of box types and sizes. With an output speed of up to 3000 boxes per hour, it exemplifies efficiency and productivity in action.

Specialized Equipment for Specific Industries

Different industries have unique packaging needs, and specialized equipment caters to these requirements. In the food packaging sector, hygiene and safety are paramount. Solutions like the Hygiene Rotary Filler & Capper from BE Machinery ensure that food products are packaged in a sterile environment, meeting strict compliance standards.

In the pharmaceutical industry, precision is key. Specialized machinery ensures that medications are packaged accurately, maintaining their integrity and safety. Similarly, in the electronics industry, packaging must protect delicate components from damage during transit. Custom machinery offers the precision and care needed for these sensitive items.

By choosing the right type of custom packaging machinery, businesses can improve their operations, ensuring products are packaged efficiently and safely. Let’s move on to discuss how these systems integrate with existing setups and the importance of maintenance and support.

Custom Packaging Machinery for Food Industry

In the food industry, hygiene, safety, and compliance are not just priorities—they are necessities. Custom packaging machinery plays a crucial role in meeting these standards, ensuring that food products are packaged in a manner that preserves their quality and safety.

Food Processing Solutions

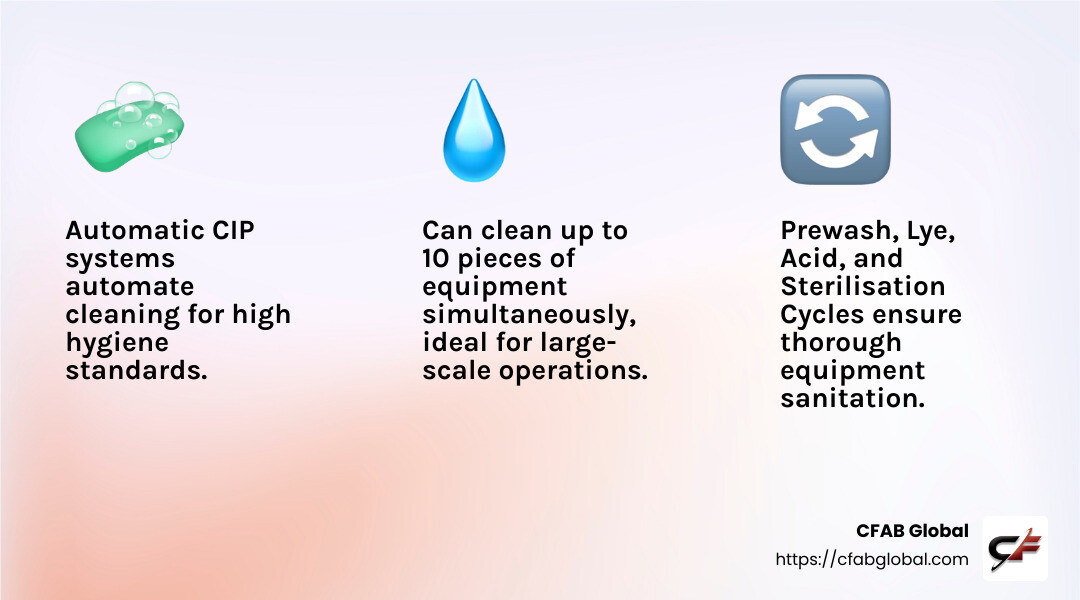

One standout solution in food processing is the Automatic CIP Cleaning Systems from BE Machinery. These systems are designed to maintain a high level of hygiene by automating the cleaning process. They use a series of cleaning cycles—such as the Prewash, Lye, Acid, and Sterilisation Cycles—to ensure that all equipment is thoroughly cleaned and sanitized.

The flexibility of these systems allows them to clean up to 10 pieces of equipment simultaneously, making them ideal for large-scale operations. This not only reduces the risk of contamination but also extends the shelf life of products by ensuring that the processing equipment is free of harmful bacteria.

Food Packaging Solutions

When it comes to food packaging, BE Machinery offers innovative solutions like the Hygiene Rotary Filler & Capper. This equipment is designed to handle sensitive food products, such as yogurt, hummus, and salad dressings, with care and precision.

The Hygiene Rotary Filler & Capper is equipped with advanced features like servo-driven dosing units and high clean filling nozzles, which ensure that products are filled accurately and hygienically. The machine’s design prevents standing water, which can harbor microorganisms, maintaining a sterile packaging environment.

Additionally, the machine’s door covers are made from tempered glass, preventing electrostatic charges that can attract dust and contaminate the filling area. This attention to detail helps companies comply with stringent food safety regulations while optimizing their packaging processes.

By investing in custom packaging machinery like these, food industry players can improve their operations, ensuring that their products are packaged safely and efficiently. This not only boosts productivity but also builds consumer trust by consistently delivering high-quality products.

Next, we’ll explore how custom packaging machinery improves operations by integrating seamlessly with existing systems and the importance of ongoing maintenance and support.

Enhancing Operations with Custom Packaging Machinery

Integration with Existing Systems

When it comes to custom packaging machinery, one of its greatest strengths is its ability to integrate seamlessly with existing systems. This compatibility ensures that operations are streamlined, reducing the risk of disruptions. Imagine a new packaging line that fits perfectly with your current setup, working in harmony to boost productivity without a hitch. This is the kind of innovation that CFAB Global champions.

By focusing on compatibility, businesses can achieve minimal disruption during implementation. This means less downtime and more consistent output. It’s like adding a new player to a well-oiled team—everything just clicks, and the game goes on smoothly.

Maintenance and Support

Once the machinery is in place, keeping it running efficiently is crucial. This is where reliability and longevity come into play. CFAB Global understands the importance of ongoing maintenance and support. With the right care, custom packaging machinery can serve a business for years, delivering consistent performance and safeguarding the investment.

Regular maintenance ensures that machinery remains in top condition, reducing the likelihood of unexpected breakdowns. This proactive approach not only extends the life of the equipment but also maintains optimal efficiency. When machinery runs smoothly, it supports the entire operation, keeping productivity high and costs low.

Moreover, having a reliable support system in place means that any issues can be addressed swiftly. This kind of support is invaluable, helping businesses steer any challenges with confidence and ease.

In the next section, we’ll address some frequently asked questions about custom packaging machinery, exploring which industries benefit most and how these solutions impact efficiency and cost.

Frequently Asked Questions about Custom Packaging Machinery

What industries benefit most from custom packaging machinery?

Custom packaging machinery offers advantages across various industries, but certain sectors see the most significant benefits. The food industry, for instance, requires strict hygiene and safety standards. Solutions like the Hygiene Rotary Filler & Capper from BE Machinery are designed to meet these needs, ensuring safe and efficient packaging of consumables.

Pharmaceuticals also benefit greatly due to the need for precision and compliance with regulatory standards. Custom machinery can be custom to handle delicate products and maintain sterility throughout the packaging process. Electronics manufacturers, on the other hand, often require specialized equipment to handle sensitive components, ensuring they are packaged without damage.

How does custom packaging machinery improve efficiency?

Efficiency is a key advantage of custom packaging machinery. By designing machinery that fits the specific needs of a production line, businesses can significantly reduce bottlenecks and improve throughput. Automation plays a crucial role here, enabling faster and more consistent packaging processes.

With custom solutions, companies can integrate advanced features like robotic systems that offer precision and speed. These systems can adapt to various packaging tasks, reducing the need for manual intervention and lowering the risk of human error. The result is a more streamlined operation that maximizes output and maintains product quality.

What are the cost implications of investing in custom packaging machinery?

While the initial investment in custom packaging machinery may be higher than standard solutions, the long-term benefits often outweigh these costs. Custom machinery is designed to optimize production, leading to reduced labor costs and less waste. Over time, these savings contribute to a lower total cost of ownership.

Additionally, the scalability of custom machinery means it can grow with a business, accommodating increased production demands without the need for frequent replacements. This adaptability ensures that the machinery remains relevant and efficient, providing a solid return on investment over its lifespan.

In the next section, we’ll conclude with a look at how CFAB Global‘s commitment to custom solutions drives operational excellence, helping businesses achieve their unique goals.

Conclusion

At CFAB Global, we understand the critical role that custom packaging machinery plays in achieving operational excellence. Our commitment to providing custom solutions helps businesses streamline their processes and meet their unique production goals effectively.

Custom solutions are at the heart of what we offer. We work closely with each client to design machinery that fits seamlessly into their existing operations. This means less downtime and more productivity, as our solutions are crafted to improve efficiency without causing disruptions. Whether it’s integrating with existing systems or providing ongoing support, our focus is on ensuring your machinery operates at its best.

Our exclusive Machine Reliability Program is a testament to our dedication to delivering value. By focusing on predictive maintenance, we help prevent breakdowns before they occur, saving you time and money. This proactive approach not only extends the lifespan of your machinery but also maximizes your return on investment.

Operational excellence is not just a goal; it’s a continuous journey. With CFAB Global as your partner, you can trust that your packaging machinery will always meet the highest standards of performance and reliability. Our expertise and customized solutions ensure that your business stays competitive and ready to face future challenges.

Choose CFAB Global for reliable machinery solutions that drive productivity and efficiency. Let us help you achieve your unique business objectives with our advanced, custom-custom equipment and services.