Introduction

Ever wondered why your machinery keeps breaking down, disrupting your workflow, and costing your company valuable time and money? Identifying the common causes of machinery breakdowns can be a game-changer.

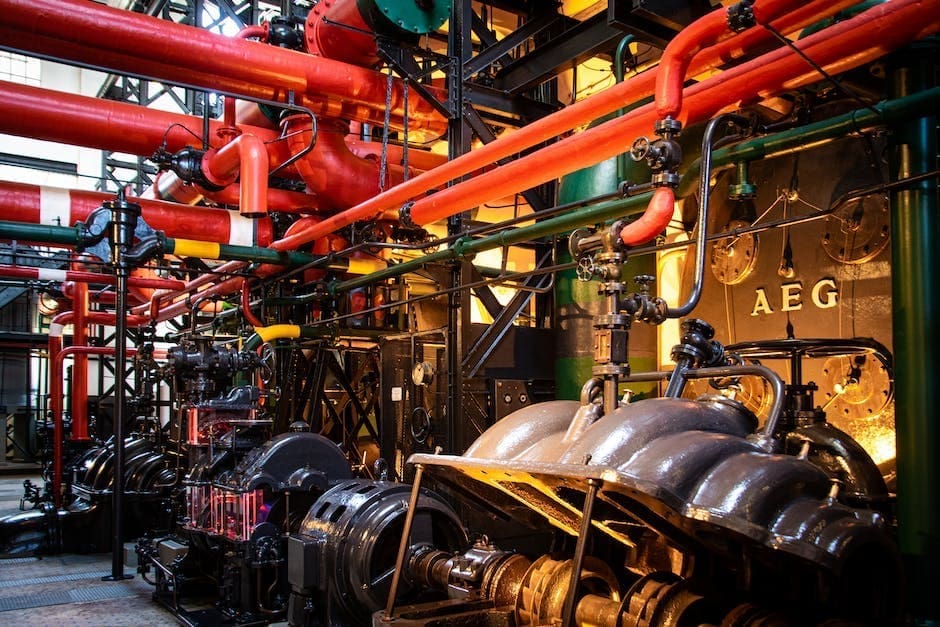

Operating industrial machinery might seem straightforward, but behind the humming mechanisms lie complex systems vulnerable to various issues, each capable of causing frustrating stalls or entire production halts. The impact can be far-reaching, creating ripple effects in production schedules, affecting workforce productivity, and even hitting the company’s bottom line.

It’s crucial to recognize these stumbling blocks and nip them in the bud. Armed with the right information, you can anticipate potential issues and put measures in place to mitigate them. This way, machinery breakdowns could become an occasional annoyance instead of a recurring nightmare.

At CFAB LLC, our mission is to boost your productivity and ensure your machinery operates optimally by helping you understand and address one of the major pain points in the industry: machinery breakdowns.

Quick Look at Common Machinery Breakdown Causes

Below are the five most common causes for machinery breakdowns:

- Improper Operation of Machinery

- Lack of or Improper Preventive Maintenance

- Overuse and Aging of Machinery

- Ignoring Warning Signals and Signs of Wear and Tear

- Poor Culture and Lack of Reliability Measures

In the sections that follow, we will delve further into each of these causes and give you advice on how you can prevent them.

The Top 5 Common Causes of Machinery Breakdowns

Understanding the common causes of machinery breakdowns can help us to implement effective preventative measures. Let’s break down these causes and discuss how you can avoid them.

Improper Operation and the Need for Adequate Training

The number one cause for machine breakdowns is improper operation due to a lack of experience or training. At CFAB LLC, we believe that anyone operating machinery needs to fully understand the machine’s manual, including how to operate, maintain, calibrate, and troubleshoot it. We also stress the importance of providing adequate training to employees, as this is not only a legal requirement but also essential to preventing machinery breakdowns.

Failure to Perform Preventive Maintenance

Another common cause of machinery breakdowns is the failure to perform preventive maintenance. Regular maintenance is crucial to keep machines in good working condition. This includes checking for signs of wear, assessing machinery for signs of poor operator technique, and looking for a build-up of excess lubricant or oil. At CFAB LLC, our Machine Reliability Program offers a comprehensive package of analysis, services, equipment, and support to ensure your machines are well-maintained.

Overuse and Aging of Machinery

Machines, like all physical assets, are subject to wear and tear. Overuse and aging of machinery can lead to failures. Constant physical stress can fast-track machine aging, causing parts to loosen or seals to crack. It’s essential to avoid pushing machines to their operational limits every time they are used.

Ignoring Warning Signals and Signs of Wear and Tear

Ignoring warning signs of damage can lead to machinery failure. On-screen warnings for issues like low hydraulic pressure should be investigated immediately. It’s important to pay attention to these warnings, no matter how minor they may seem, as they can be indicative of more serious underlying issues.

Poor Culture and Lack of Reliability Measures

Lastly, a poor culture and a lack of reliability measures can lead to machinery breakdowns. This includes ignoring routine maintenance, neglecting to provide proper training, or failing to address machine issues promptly. At CFAB LLC, we understand the importance of a strong reliability culture in preventing breakdowns and maintaining productivity.

By understanding these common causes of machinery breakdowns, you can take necessary preventative measures to reduce equipment downtime, extend machinery lifespan, and improve productivity. Stay tuned for our next section where we discuss the need for proper lubrication and cleaning, and the role of high-quality products like TRC Grease & Lubricant in maintaining your machinery.

The Need for Proper Lubrication and Cleaning

One of the most common causes of machinery breakdowns is improper or inadequate lubrication and cleaning. Let’s dive deeper into this topic.

Role of Lubrication in Preventing Machinery Breakdowns

A well-lubricated machine is a happy machine. Lubrication plays a crucial role in reducing friction between machinery parts. This keeps the machine running smoothly and helps to prevent wear and tear. Poor lubrication can result in unnecessary friction, leading to overheating, parts wearing out quickly, and eventually, machinery breakdown.

Regular checks of oil temperature and lubrication levels are essential to ensure your machinery remains in good working condition. It’s also important to know how much lubrication your machinery requires. This information can usually be found in the operational manual or through proper training.

Importance of Using Quality Lubricants like TRC Grease & Lubricant Products

When it comes to lubrication, not all products are created equal. At CFAB LLC, we believe in using only the best products for our machinery, which is why we are proud Authorized Independent Sales Consultants for TRC Grease & Lubricant Products.

TRC Grease & Lubricant Products are known for their superior quality and effectiveness. Using these products helps to ensure that your machinery is lubricated correctly, reducing unnecessary wear and tear, and prolonging the lifespan of your machinery.

The Impact of Cleaning on Machinery Lifespan

Besides lubrication, another aspect that plays a significant role in machinery maintenance is cleanliness. Dust, dirt, and grease can interfere with electrical connections and machinery functioning. Regular cleaning, especially around all electrical connections and other areas of buildup, can prevent these problems.

Compressed air is generally better and safer for cleaning machinery than water, as it helps to prevent rust, which can be detrimental to metal machinery. Proper storage is also crucial to prevent rust and other damage due to exposure to oxygen or moisture.

In conclusion, regular lubrication using high-quality products like TRC Grease & Lubricant and thorough cleaning are essential in preventing machinery breakdowns. At CFAB LLC, we understand the importance of these tasks and are here to help you maintain your machinery to its highest standard. Stay tuned for our next section where we discuss the role of preventive maintenance in avoiding machinery breakdowns.

The Role of Preventive Maintenance in Avoiding Machinery Breakdowns

Preventive maintenance is a crucial aspect of machinery upkeep that is often overlooked. Its role in preventing machinery breakdowns cannot be overstated.

Understanding the Concept of Preventive Maintenance

Preventive maintenance is a proactive approach that involves regular inspections, servicing, and repairs to prevent potential equipment failures. It’s akin to going for regular health check-ups to prevent diseases. Regular wear and tear is natural, but preventive maintenance ensures that any wear or damage is identified and rectified early. This way, machinery can operate at optimal efficiency without sudden breakdowns disrupting productivity.

How CFAB LLC’s Machine Reliability Program Facilitates Preventive Maintenance

At CFAB LLC, we have a comprehensive Machine Reliability Program that offers a customized package of analysis, services, equipment, and support for your machinery needs. We understand that each machinery setup is unique and thus requires a tailored approach to maintenance.

Our program not only focuses on routine checks but also on the continuous monitoring of equipment. This allows us to establish a baseline of what good equipment condition looks like and detect subtle changes that could lead to breakdowns. With this data, we can predict and prevent breakdowns, allowing more time for contingency planning and minimizing production interruptions.

The Balance Between Too Much and Too Little Preventive Maintenance

Just as too little preventive maintenance can lead to machinery breakdowns, too much of it can also pose problems. It’s a bit of a Goldilocks situation. When you get into a machine to maintain it, you open up the equipment to a whole set of risks. Over time, these risks can compound and lead to machine failure.

Striking the right balance is key. At CFAB LLC, we help you find that balance. Our preventive maintenance schedule is not just based on a predefined timeline or usage, but it also takes into account the actual operating condition of the asset.

In conclusion, preventive maintenance is a proactive approach to machinery upkeep that can significantly reduce the risks of breakdowns. At CFAB LLC, our Machine Reliability Program is designed to facilitate effective preventive maintenance and help you strike the right balance to maximize machinery lifespan and productivity.

The Importance of a Strong Reliability Culture

A crucial factor, often overlooked in discussions about common causes of machinery breakdowns, is the culture of the organization. Specifically, the culture of reliability within the company can significantly impact the frequency and severity of machinery breakdowns.

What is a Reliability Culture and Why is it Important?

A reliability culture is a workplace environment where everyone, from top management to the frontline staff, values and prioritizes the reliable performance of machinery. In such a culture, there is a strong emphasis on preventive maintenance, adequate training, and sound operational procedures.

The importance of a reliability culture cannot be overstated. As the Boeing 737 Max aircraft crashes demonstrated, a culture of rushing production and ignoring reliability can lead to catastrophic results. On the other hand, a strong reliability culture can help prevent machinery breakdowns, reduce downtime, extend machinery lifespan, and ultimately, increase productivity.

How CFAB LLC Promotes a Strong Reliability Culture

At CFAB LLC, we understand the importance of a strong reliability culture. We not only promote it within our organization but also help our clients establish it in theirs.

We believe in the power of preventive maintenance and the necessity of regular check-ups to optimize machinery performance. Our Machine Reliability Programs offer tailored analysis, services, and support to help our clients establish a solid preventive maintenance routine.

Equally, we understand the importance of having well-trained operators. Hence, we offer training to our staff and our clients on appropriate operating procedures, basic troubleshooting, and best practices for safe equipment use.

Furthermore, we foster a culture where warning signs and indicators of wear and tear are not ignored, but rather, timely addressed. This proactive approach helps prevent minor issues from escalating into major breakdowns.

The Impact of a Strong Reliability Culture on Machinery Lifespan and Productivity

A strong reliability culture has a significant positive impact on both the lifespan of machinery and the productivity of the organization.

When machinery is regularly maintained and properly operated, it not only lasts longer but also runs more efficiently. This reduces downtime due to breakdowns and ensures consistent, high-quality output.

Moreover, when reliability is valued, it encourages a proactive approach to machinery maintenance rather than a reactive one. This saves time and resources in the long run and contributes to increased productivity.

In conclusion, a strong reliability culture is a crucial factor in preventing machinery breakdowns. By prioritizing reliability, investing in training, and establishing effective preventive maintenance routines, organizations can significantly reduce machinery breakdowns and enhance productivity. At CFAB LLC, we are committed to helping our clients achieve this.

Conclusion

Recap of the Top 5 Reasons for Machinery Breakdowns and Their Prevention

Understanding the common causes of machinery breakdowns is the first step towards preventing them. The top five reasons include improper operation, lack of preventive maintenance, overuse and aging, ignoring warning signals, and a poor reliability culture.

To counteract these causes, we recommend proper training to ensure correct operation of machinery, regular preventive maintenance to identify potential issues early, careful monitoring of machine use to avoid overworking the equipment, paying keen attention to warning signals and signs of wear and tear, and fostering a strong reliability culture within your organization.

Final Thoughts on the Importance of Preventive Measures in Machinery Maintenance

Preventive measures in machinery maintenance are often neglected, yet they play a critical role in preventing breakdowns and enhancing the lifespan of your machinery. Regular maintenance, correct operation, and the use of high-quality lubricants like TRC Grease & Lubricant Products can significantly reduce the risk of machinery breakdowns.

Monitoring your equipment’s condition continuously allows you to detect subtle changes which can be used to predict breakdowns and failures. This not only saves costs associated with repairs but also avoids downtime, thereby boosting productivity.

How CFAB LLC Can Help in Preventing Machinery Breakdowns

At CFAB LLC, we understand the detrimental impact of machinery breakdowns on your business. That’s why we have developed a comprehensive Machine Reliability Program tailored to meet your specific needs.

Our program encompasses a package of analysis, services, equipment, and support designed to enhance productivity, reduce equipment downtime, and extend the life of your machinery. We use our expertise to recommend and implement preventive measures, provide high-quality lubricants, and offer continuous support to ensure your machinery functions at its best.

We believe in the power of a strong reliability culture and strive to impart this within your organization. Our ultimate goal is to minimize the risk of lost-time production and help you achieve optimal efficiency.

In conclusion, understanding the common causes of machinery breakdowns and implementing preventive measures is crucial in maintaining the health of your machinery. At CFAB LLC, we are here to support you every step of the way.