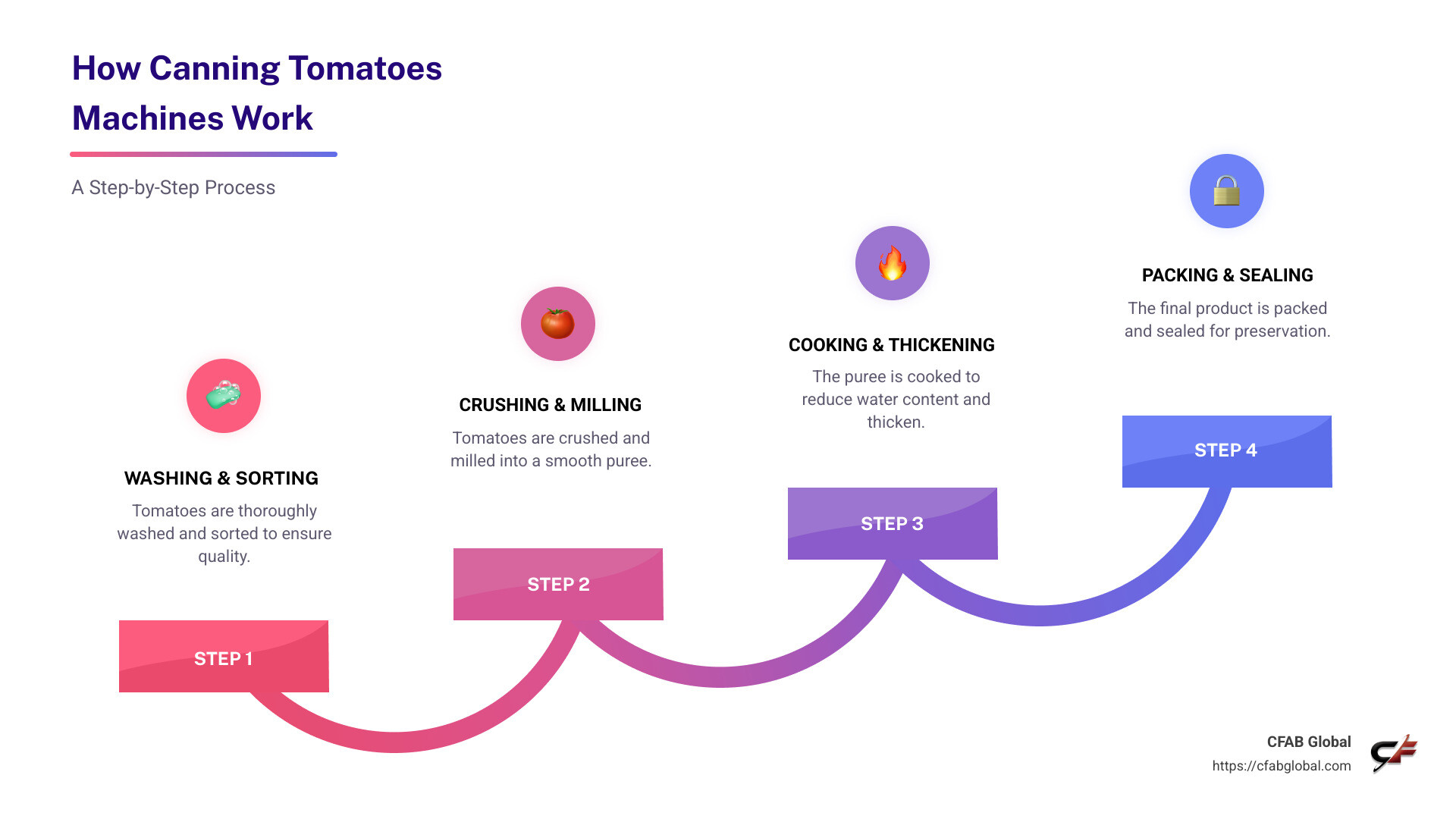

Canning tomatoes machine technology has revolutionized tomato processing by streamlining every step from garden to jar. These machines are designed to automate and simplify the canning process, ensuring that tomatoes are efficiently cooked, packed, and sealed while maintaining their freshness and nutritional value.

- Automated Efficiency: Machines perform multiple canning stages, significantly reducing manual labor.

- Preservation Quality: Advanced sealing techniques ensure long shelf life and prevent spoilage.

- Consistent Output: Ensures uniformity in product quality and quantity.

In today’s market, understanding the machinery behind tomato processing helps manufacturers meet growing consumer demands while ensuring product quality.

I’m Todd Cleppe, CEO at CFAB Global. With over 25 years of experience in machinery process improvements, I’ve seen first-hand the transformative power of canning tomatoes machines in various industries. These machines are essential for efficient production and a key component in delivering quality canned products. Let’s dive deeper into how they work and their role in the canning industry.

The Role of Canning Tomatoes Machines

Tomato canning machines play a crucial role in changing fresh tomatoes into delicious, shelf-stable products. These machines, including tomato milling machines, tomato squeezers, and tomato juicers, automate the process to ensure efficiency and quality.

Tomato Milling Machines

Tomato milling machines are designed to process large quantities of tomatoes quickly. They remove skins and seeds, leaving only the pulp and juice, which are essential for sauces and pastes. These machines save time and reduce labor by handling tasks that would otherwise require manual effort.

Tomato Squeezers

Tomato squeezers are specialized machines that extract juice from tomatoes with minimal waste. They are ideal for producing fresh tomato juice, which can be used directly or as a base for other products. By efficiently separating juice from the pulp, these machines ensure that every part of the tomato is used.

Tomato Juicers

Tomato juicers are versatile tools that can be used in both small-scale and large-scale operations. They are designed to produce smooth, seed-free juice, perfect for commercial canning. These machines maintain the nutritional value and flavor of the tomatoes, making them a favorite choice for many food manufacturers.

Incorporating canning tomatoes machines into your production line not only improves productivity but also ensures a consistent, high-quality product. These machines are integral to meeting the demands of modern consumers who expect fresh, flavorful, and nutritious canned tomatoes.

By understanding the capabilities and benefits of various canning machines, manufacturers can optimize their operations and deliver superior products to the market.

Types of Tomato Canning Machines

When it comes to preserving tomatoes, choosing the right canning tomatoes machine is essential. There are several types available, each suited for different needs. Let’s explore the main categories: manual machines, automatic machines, and multi-purpose units.

Manual Machines

Manual machines are the simplest type of tomato canning equipment. They require physical effort to operate, making them ideal for small-scale or home use. These machines are often referred to as “hand-crank” models. They are cost-effective and easy to maintain.

Advantages of Manual Machines:

- Affordable: Great for those on a budget.

- Simple to Use: No need for electricity or complex setups.

- Portable: Easy to move and store.

Manual machines are perfect for hobbyists or those who enjoy the traditional method of canning.

Automatic Machines

For larger operations, automatic machines are a game-changer. They streamline the canning process, reducing manual labor and increasing efficiency. With advanced features, these machines can handle everything from filling to sealing cans. When considering automatic solutions, BE Machinery offers a range of high-quality options that ensure precision and versatility.

Key Features of Automatic Machines:

- High Efficiency: Can process large volumes quickly.

- Precision: Ensures consistent quality with every can.

- Versatile: Suitable for various can sizes and materials.

Automatic machines are ideal for businesses looking to scale up production without compromising on quality.

Multi-Purpose Units

Multi-purpose units offer flexibility by performing multiple functions in one machine. These units can mill, juice, and can tomatoes, making them a versatile choice for any production line.

Benefits of Multi-Purpose Units:

- Space-Saving: Combines several processes in one machine.

- Cost-Effective: Reduces the need for multiple pieces of equipment.

- Adaptable: Can be used for various products beyond tomatoes.

These units are perfect for businesses that want to maximize their investment and adaptability in production.

By understanding the different types of canning tomatoes machines, you can choose the one that best fits your needs, ensuring efficient and high-quality tomato preservation.

How to Choose the Right Canning Tomatoes Machine

Selecting the best canning tomatoes machine involves considering several important factors: precision, efficiency, and budget. Additionally, it’s crucial to explore solutions from reputable providers like BE Machinery for food packaging equipment.

Precision

Precision is key in canning tomatoes. A machine with high precision ensures that each can is filled and sealed correctly, minimizing waste and maintaining quality. Automatic machines excel in this area. They offer consistent results, which is crucial for businesses that need to meet strict quality standards. Look for features like high-standard special sensors that maintain accuracy throughout the process. Consider exploring BE Machinery’s solutions for advanced precision in food packaging.

Efficiency

Efficiency can make or break your canning operation. Automatic and multi-purpose units shine here, as they can handle large volumes with minimal manual intervention. These machines often come equipped with advanced technology that allows for rapid processing without sacrificing quality. For example, some machines can achieve filling speeds of up to 30 cans per minute, making them ideal for high-demand settings. BE Machinery offers efficient solutions that can enhance your canning process.

Budget

Budget is always a consideration when investing in equipment. Manual machines are the most budget-friendly option, perfect for small-scale operations or home use. They are affordable and easy to maintain, making them a great choice for those just starting out. However, if you have a larger budget, automatic machines offer long-term value by increasing productivity and reducing labor costs. For high-quality automatic solutions, consider BE Machinery’s offerings.

When deciding on a canning tomatoes machine, weigh the importance of precision, efficiency, and budget according to your specific needs. Whether you’re a hobbyist or a commercial producer, there’s a machine out there that fits your requirements.

Frequently Asked Questions about Canning Tomatoes

What is the best method for canning tomatoes?

The best method for canning tomatoes largely depends on your equipment and preference. Hot water bath canning is a popular choice for many home canners. This method involves submerging jars of tomatoes in boiling water to ensure they are sealed properly. It is ideal for high-acid foods like tomatoes, which naturally inhibit the growth of harmful bacteria.

Pressure canning is another effective method. It uses a specialized pressure canner to reach higher temperatures than a water bath, ensuring the destruction of spores, such as those of Clostridium botulinum. This bacteria can cause botulism, a rare but serious illness, making pressure canning a safer option, especially for low-acid foods.

For those looking to streamline the canning process, consider using advanced food processing solutions like the Hygiene Rotary Filler & Capper from BE Machinery. These machines can significantly simplify the canning process, ensuring efficiency and safety.

Is it safe to can tomatoes without a pressure canner?

Yes, it is safe to can tomatoes without a pressure canner if you use the water bath method and ensure proper hot packing. Hot packing involves heating your tomatoes before placing them in jars. This process helps in killing bacteria and enzymes that can spoil the food. However, it’s crucial to add acid, like lemon juice or vinegar, to each jar to ensure the acidity levels are high enough to prevent bacterial growth.

How long do canned tomatoes last?

Canned tomatoes can last a long time when stored properly. High-acid foods like tomatoes are generally safe to consume for up to 12 to 18 months. However, store them in a cool, dark place to maintain their quality. Always check for signs of spoilage before use, such as bulging lids or off-smelling contents, to ensure safety.

Understanding these methods and safety measures, along with utilizing efficient canning machines, can help you enjoy your home-canned tomatoes for months to come.

Conclusion

At CFAB Global, we understand the importance of reliable machinery in the food processing industry, especially when it comes to canning tomatoes. Our commitment to enhancing operational efficiency and reducing downtime is evident through our Machine Reliability Program. This program is designed to ensure that your equipment operates at peak performance, providing you with the precision and efficiency needed for successful tomato canning.

Our Machine Reliability Program is not just a set of services; it’s a partnership. We work closely with our clients to tailor solutions that meet their specific needs, ensuring that their machinery remains dependable and productive. Whether you’re using a canning tomatoes machine or other food processing equipment, our program offers personalized analysis and ongoing support to maximize your return on investment.

By choosing CFAB Global, you’re opting for a partner that prioritizes your success. Our expertise in machinery solutions spans various industries, and our dedication to proactive maintenance helps prevent breakdowns before they occur. This means less downtime and more time focusing on what matters most—producing quality canned tomatoes that meet your standards.

For more information on how CFAB Global can support your food processing operations, visit our Food Processing Equipment page. Let us help you achieve greater efficiency and reliability in your canning process.