Air flow divider devices are essential components for efficient flow management in various industrial applications. These dividers split a single stream of fluid or air into multiple outlets, distributing the flow equally or as required by specific conditions. Industries such as manufacturing, aviation, and energy rely on these components to ensure consistent performance and to optimize the distribution of resources.

- Key Benefits of an Air Flow Divider:

- Ensures equal distribution in complex systems.

- Improves machinery performance by managing flow precisely.

- Reduces downtime by preventing overload in any single part of the system.

Understanding the role of air flow dividers helps in maintaining an efficient and reliable operation. These precision devices work by splitting airflow, helping manage pressures and flow rates through different paths. In the aviation sector, for example, Precision Airmotive’s flow dividers are critical in fuel injection systems, ensuring each engine component receives the optimal amount of fuel to function effectively.

As someone deeply involved in designing automated lubrication systems, I am Todd Cleppe, CEO & Co-Founder of CFAB Global. Over my career, innovations in components like the air flow divider have dramatically improved machinery efficiency and reliability across various industries. Stay tuned as we dig deeper into the fascinating world of air flow dividers and their impact on modern manufacturing processes.

Air flow divider word roundup:

– flow divider valves

– how does a hydraulic flow divider valve work

– pressure compensated flow divider

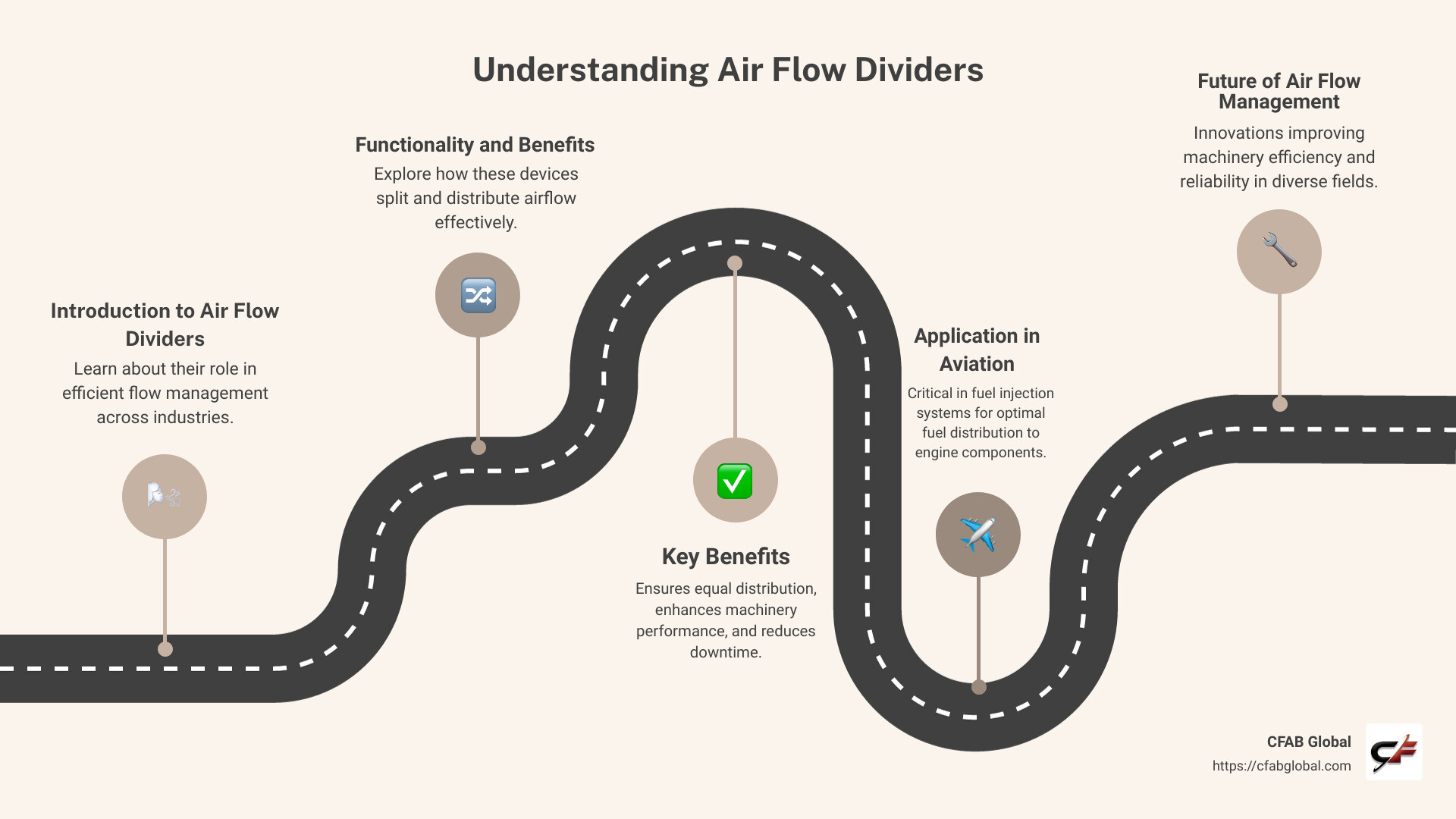

Understanding Air Flow Dividers

An air flow divider is a critical component in fluid systems, ensuring the efficient distribution of air or fluid across multiple channels. These devices are engineered to split a single input stream into several output paths, ensuring each path receives the right amount of flow, even when there are pressure differences.

Flow Divider Function

The primary function of an air flow divider is to split and manage the flow of air or fluids. By doing so, it maintains system balance and efficiency. In complex systems, this ensures that each component receives its required portion of the flow, preventing overload or underperformance in any section. This is particularly vital in systems where precise flow control is necessary, like in aviation fuel injection systems, where Precision Airmotive’s flow dividers play a key role.

Pressure Differences

Pressure differences within a system can cause uneven distribution of air or fluid, leading to inefficiencies or potential system failures. Air flow dividers help mitigate these pressure differences, ensuring that each output path maintains consistent pressure levels. This is crucial for maintaining the reliability and performance of systems, especially in high-stakes industries like aviation and manufacturing.

Flow Paths

The design of an air flow divider allows it to manage multiple flow paths effectively. By controlling how the flow is divided among these paths, the system can achieve optimal performance. This involves not only splitting the flow but also compensating for any variations in pressure or demand across different paths. For instance, in a manufacturing setup, having a reliable flow divider can improve the precision and efficiency of automated processes.

Air flow dividers are indispensable in numerous applications, ensuring that systems run smoothly and efficiently. Whether in aviation, manufacturing, or energy sectors, these devices play a pivotal role in maintaining balance and optimizing performance.

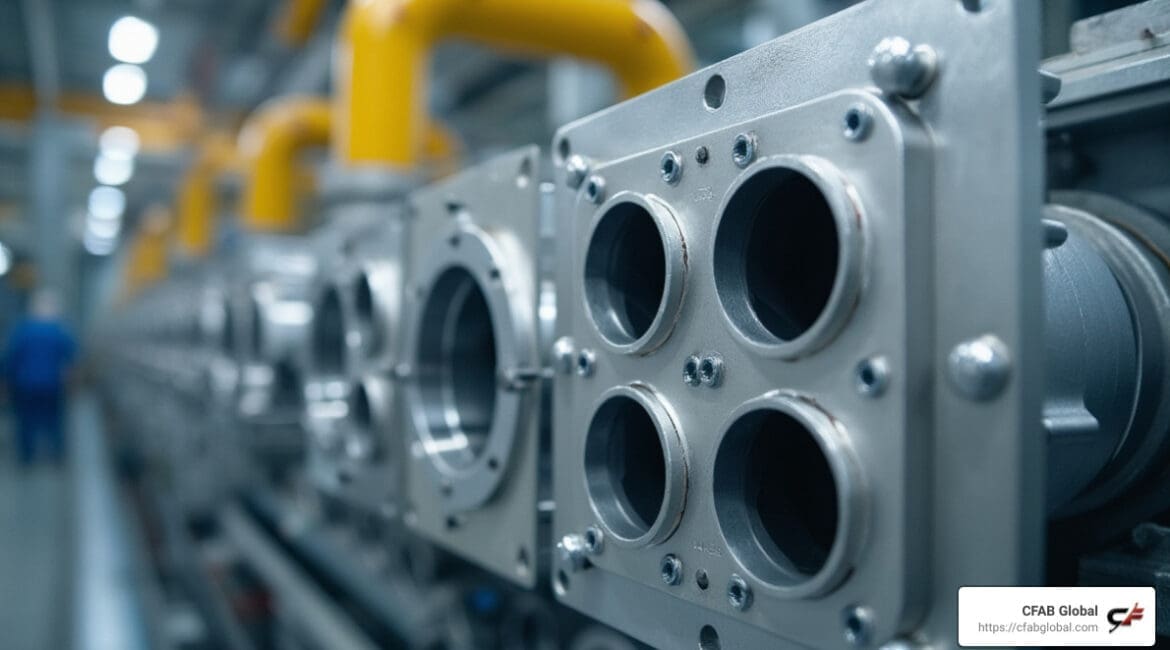

Top Air Flow Divider Products

When it comes to air flow dividers, CFAB Global stands out for its commitment to quality and performance. These products are integral to fuel injection systems, which are critical in aviation for precise fuel distribution.

FLOW DIVIDER – 2576624-1

The 2576624-1 flow divider is a key component in fuel injection systems. Known for its precision, this model ensures that each engine nozzle receives the exact amount of fuel required for optimal performance. CFAB Global manufactures these dividers to meet stringent engine manufacturer specifications, ensuring reliability and efficiency.

FLOW DIVIDER – 2576564-1

Another reliable product is the 2576564-1 flow divider. Like its counterparts, it plays a crucial role in managing fuel flow within aviation engines. This model is designed to handle the pressures and demands of high-performance aircraft, maintaining consistent fuel distribution even under varying operating conditions.

FLOW DIVIDER – 2576556-1

The 2576556-1 model is engineered for precision and durability. It is part of CFAB Global’s range of flow dividers that uphold the company’s reputation for excellence. This product ensures that fuel is evenly split among engine nozzles, supporting the smooth operation of aircraft engines.

FLOW DIVIDER – 2576532-1

The 2576532-1 flow divider is crafted with attention to detail, ensuring it meets the high standards set by engine manufacturers. It is designed to provide precise fuel flow control, which is essential for maintaining engine performance and efficiency in various flight conditions.

FLOW DIVIDER – 2576526-1

Lastly, the 2576526-1 model is a testament to CFAB Global’s dedication to quality. This flow divider is integral to the fuel injection system, ensuring that each engine receives the correct fuel flow. Its robust design and reliable performance make it a preferred choice in the aviation industry.

In summary, CFAB Global offers a range of flow dividers that are pivotal in aviation fuel injection systems. These products are designed to meet the rigorous demands of the industry, ensuring precision, reliability, and efficiency in fuel flow management.

How Air Flow Dividers Work

Air flow dividers are essential components in various systems, particularly in aviation and industrial applications. They are designed to control the flow of air or fluids, ensuring that each path or nozzle receives the precise amount needed for optimal performance.

Flow Control

At the heart of any air flow divider is its ability to regulate the distribution of flow. This is crucial in applications like the RSA® fuel injection systems, where precise fuel delivery to each engine nozzle is vital. Flow dividers achieve this by splitting the incoming flow into multiple paths, each calibrated to deliver a specific volume. This ensures consistent performance, even in complex systems with varying demands.

Pressure Compensation

One of the challenges in managing flow is dealing with pressure differences. Air flow dividers are equipped with mechanisms that provide pressure compensation. This feature allows them to adjust the flow paths dynamically, maintaining an even distribution despite fluctuations in pressure. This is particularly important in high-performance environments such as aviation, where maintaining stable pressure across all nozzles can significantly impact engine efficiency and reliability.

Flow Paths

The design of flow paths within a divider is critical. These paths are engineered to minimize resistance and ensure smooth flow distribution. In Precision Airmotive®’s products, for instance, the flow paths are carefully crafted to match the engine manufacturer’s specifications. This precision engineering helps in reducing turbulence and maintaining a steady flow, which is essential for the optimal functioning of fuel injection systems.

In summary, air flow dividers play a crucial role in managing and optimizing flow within complex systems. Through precise flow control, effective pressure compensation, and well-designed flow paths, they ensure that each component receives exactly what it needs to function efficiently. This makes them indispensable in industries that demand high precision and reliability.

Frequently Asked Questions about Air Flow Dividers

What does a flow divider do?

A flow divider is a key component that splits and directs the flow of air or fluids into multiple paths. This is crucial in systems where precise flow distribution is required. In aviation, for example, a flow divider ensures that each engine nozzle receives the exact amount of fuel needed for optimal performance. This helps maintain engine efficiency and reliability by balancing the flow despite varying demands.

How accurate is a rotary flow divider?

Rotary flow dividers are known for their high accuracy in splitting flows. These devices use a rotating mechanism to divide the flow evenly between multiple outlets. The precision of a rotary flow divider is vital in applications where even slight variations in flow can lead to performance issues. Their design allows for minimal leakage and high repeatability, making them suitable for tasks that require exact flow distribution.

What is a flow divider in aviation?

In aviation, a flow divider is integral to the fuel injection system. It controls the fuel flow to each of the engine’s nozzles, ensuring that the engine runs smoothly and efficiently. By maintaining an even distribution of fuel, flow dividers help prevent engine misfires and optimize combustion. This precision is crucial, as any imbalance can significantly affect an aircraft’s performance and safety.

Flow dividers in aviation are carefully engineered to meet stringent specifications, ensuring they can withstand the high-pressure environments typical of aircraft engines. This makes them indispensable for maintaining the engine’s reliability and performance.

In conclusion, flow dividers are essential for precise flow management in various applications, from industrial systems to high-stakes aviation environments. Their ability to split flow accurately, compensate for pressure differences, and ensure optimal distribution makes them a vital component in many industries.

Conclusion

At CFAB Global, we understand the critical role that air flow dividers play in maintaining operational efficiency across diverse industries. As a leader in providing advanced machinery solutions, we prioritize delivering equipment that aligns with the highest standards of reliability and performance. Our offerings are designed to meet the specific demands of industries ranging from aviation to manufacturing, ensuring that every component, including flow dividers, operates at peak efficiency.

Our Machine Reliability Program is at the core of our commitment to excellence. This comprehensive solution is custom to improve the performance, reliability, and lifespan of your machinery. By focusing on predictive maintenance and customized strategies, we help reduce costly downtime and extend the life of critical components.

Through our program, we provide:

-

Personalized Analysis: We work closely with each client to design a strategy that fits their unique needs.

-

High-Quality Equipment: Our selection of top-tier products ensures that your machinery operates smoothly and efficiently.

-

Ongoing Support: From initial consultation to post-implementation, we are with you every step of the way.

For industries like aviation, where precision in flow management is non-negotiable, our solutions ensure that components like flow dividers function flawlessly. This precision is vital for maintaining engine efficiency and safety, as even minor discrepancies can lead to significant performance issues.

By choosing CFAB Global, you are partnering with a team dedicated to your success. Our expertise, coupled with our commitment to providing custom solutions, ensures that your machinery not only meets but exceeds industry expectations.

For more information on how CFAB Global can improve your operational efficiency, visit our Graco service page.