Agricultural machinery maintenance is an essential practice for ensuring farm equipment operates efficiently and prevents costly downtime. In the field of agriculture, where time is of the essence, machinery breakdowns can lead to significant disruptions. Here’s how regular maintenance helps:

- Prevents Breakdowns: Routine checks can stop problems before they start.

- Boosts Productivity: Well-maintained machinery runs smoother, increasing productivity.

- Extends Equipment Life: Proper care prolongs the lifespan of machinery.

By keeping machinery in top condition, farmers can avoid the headaches that come with unexpected repairs or replacements.

I’m Todd Cleppe, CEO & Co-Founder at CFAB Global. Over my 25 years in the field, I’ve seen how effective agricultural machinery maintenance can transform operations. My expertise lies in crafting solutions that reduce downtime and improve equipment performance—saving time and money.

Understanding Agricultural Machinery Maintenance

Agricultural machinery maintenance is more than just routine check-ups; it’s a strategic approach to keeping your farm equipment in top shape. Let’s break it down into three key areas: types of maintenance, safety, and cost savings.

Types of Maintenance

-

Preventive Maintenance: This involves regular, scheduled maintenance tasks designed to prevent breakdowns. Think of it as a health check-up for your machines. It includes oil changes, lubrication, and inspections. Using quality lubricants, such as those from Texas Refinery Corp, ensures your equipment runs smoothly.

-

Predictive Maintenance: Here, technology plays a role. By using sensors and data analysis, you can predict when a machine might fail and fix it before it does. This approach is gaining traction as connectivity and data analytics improve in agriculture.

-

Corrective Maintenance: This is the traditional “fix it when it’s broken” approach. It’s less efficient and often more costly, but sometimes necessary for unexpected issues.

Safety First

Safety is a top priority in agriculture. Well-maintained equipment is safer to operate. Regular maintenance checks can uncover potential hazards, such as faulty brakes or worn-out tires. Ensuring all lights and batteries are functional also improves safety, especially during early morning or late-night operations.

Cost Savings

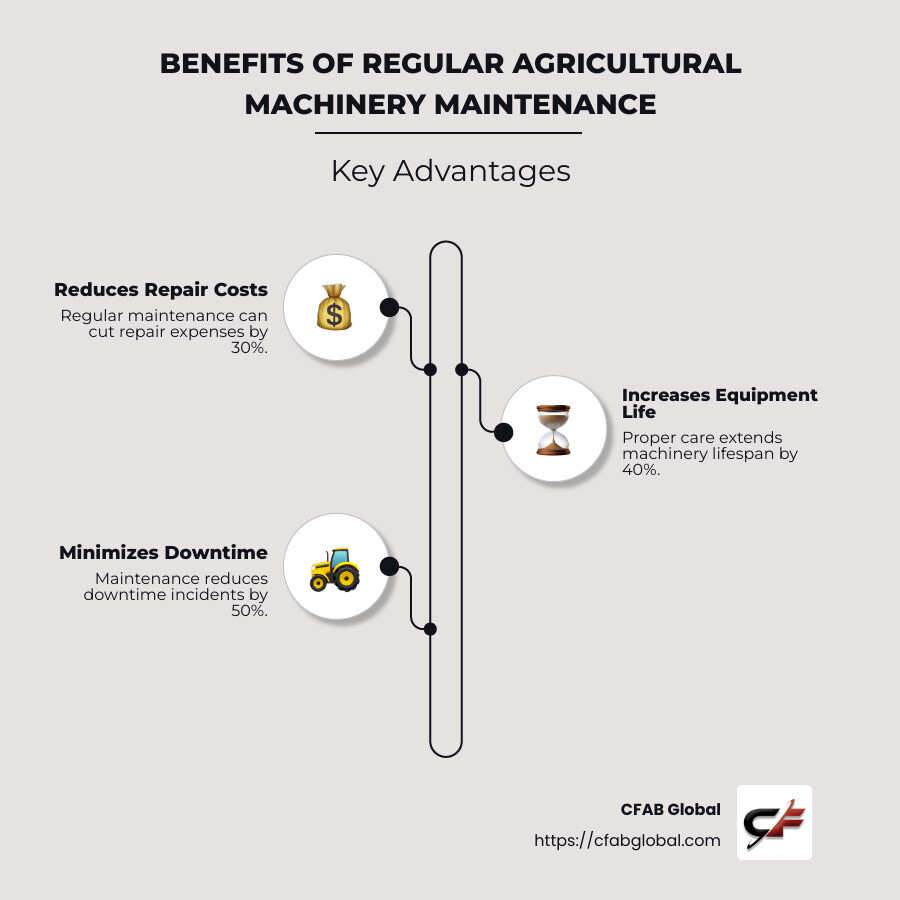

Investing time and resources in agricultural machinery maintenance can lead to significant cost savings. Here’s how:

- Reduced Repair Costs: Preventive maintenance can catch small issues before they become costly repairs.

- Longer Equipment Life: Regular care extends the lifespan of your machinery, delaying the need for expensive replacements.

- Improved Fuel Efficiency: Well-maintained machines run more efficiently, saving on fuel costs.

By adopting a proactive maintenance strategy, farmers can keep their operations running smoothly and economically. As Todd Cleppe, CEO & Co-Founder at CFAB Global, emphasizes, “Effective maintenance transforms operations, reducing downtime and enhancing performance.”

Next, we’ll explore 10 Essential Farm Equipment Maintenance Tips to help you implement these strategies effectively.

10 Essential Farm Equipment Maintenance Tips

Keeping your farm equipment in top condition is crucial for minimizing downtime and maximizing efficiency. Here are 10 essential tips that will help you maintain your machinery effectively:

1. Keep All Documents Organized

Start by organizing all your equipment-related documents. This includes manuals, service logs, and warranties. Having these records at your fingertips makes it easier to track maintenance schedules and past repairs.

2. Perform Regular Oil Changes

Regular oil changes are vital for the smooth operation of your machinery. Follow the manufacturer’s recommendations for oil change intervals. Consider using high-quality lubricants, like those from Texas Refinery Corp, to ensure optimal performance.

3. Lubricate Moving Parts

Lubricating moving parts reduces friction and extends the lifespan of your equipment. Make it a routine task to apply lubricants to bearings, joints, and other critical areas.

4. Check All Hitches and Tires

Inspect hitches and tires regularly. Ensure hitches are secure and tires are properly inflated. This not only improves safety but also improves fuel efficiency.

5. Inspect Any Lights on the Vehicle and the Batteries

Functional lights and batteries are essential for safe operation, especially during low-light conditions. Regularly check and replace faulty bulbs and ensure batteries are charged and in good condition.

6. Calibrate Special Equipment

For specialized machinery, regular calibration is key to maintaining accuracy and performance. Follow the manufacturer’s guidelines to ensure your equipment operates at its best.

7. Keep Machinery Clean

Dirt and debris can lead to corrosion and other issues. Clean your machinery regularly to maintain its functionality and prevent long-term damage.

8. Inspect for Damage

Routine inspections can help you spot signs of damage early. Look for cracks, dents, or leaks, and address them promptly to prevent more significant issues.

9. Store Equipment Indoors When Possible

Whenever feasible, store your equipment indoors. This protects it from harsh weather conditions and prolongs its lifespan.

10. Avoid Customizing or Modifying Engines

While it might be tempting to modify your machinery for better performance, unauthorized changes can void warranties and pose performance risks. Always consult the manufacturer before making modifications.

By following these agricultural machinery maintenance tips, you can reduce downtime, boost efficiency, and keep your farm equipment running smoothly. Next, we’ll dig into how technology can improve your maintenance strategies with the use of CMMS and other tools.

Keep All Documents Organized

Keeping your agricultural machinery maintenance documents organized is the first step toward efficient equipment management. Here’s why it’s important and how to do it effectively:

Why Organize Your Documents?

-

Easy Access to Information: Having all your records, service logs, and warranties in one place allows you to quickly find the information you need when scheduling maintenance or addressing issues.

-

Tracking Maintenance History: Organized documents help track past repairs and routine maintenance. This ensures you don’t miss any important service intervals, which can prevent costly breakdowns.

-

Warranty Claims: In case of equipment failure, having all warranty information readily available can expedite the claims process and save you money on repairs.

How to Organize Your Documents

-

Create a Filing System: Use a physical filing cabinet or digital storage system to categorize your documents. Label folders by equipment type or maintenance task.

-

Maintain a Service Log: Keep a detailed log of all maintenance performed, including dates, tasks completed, and any parts replaced. This log serves as a valuable reference for future maintenance planning.

-

Digital Management Tools: Consider using farm equipment management software to store and manage your documents digitally. This can include uploading PDFs of manuals and warranties, making them easily accessible from any device.

Benefits of Organized Documentation

-

Improved Efficiency: Quick access to maintenance records and service schedules helps keep your equipment in top shape, reducing downtime and boosting productivity.

-

Informed Decision-Making: With all your data organized, you can make better-informed decisions about equipment upgrades, repairs, and replacements.

-

Improved Communication: If you work with a team, having a centralized system for documentation ensures everyone has access to the same information, reducing misunderstandings and errors.

By taking the time to organize your agricultural machinery maintenance documents, you lay the groundwork for a more efficient and effective maintenance strategy. Next, we’ll explore the importance of performing regular oil changes and how they contribute to the longevity of your farm equipment.

Perform Regular Oil Changes

Regular oil changes are crucial for maintaining the health of your agricultural machinery. This simple but essential task can save you time, money, and headaches in the long run. Let’s break down why oil changes are so important and how to do them right.

Lubrication: The Lifeblood of Your Machinery

Oil serves as the lifeblood of your equipment, providing necessary lubrication to keep moving parts functioning smoothly. Without proper lubrication, components can grind against each other, leading to increased wear and tear. This not only shortens the lifespan of your machinery but also increases the risk of unexpected breakdowns.

- Texas Refinery Corp products offer high-quality lubricants specifically designed for agricultural machinery. Using the right oil can significantly extend the life of your equipment.

Oil Analysis: Stay Ahead of Problems

Performing regular oil analysis is like having a health check-up for your machinery. By analyzing the oil, you can detect potential issues before they become serious problems. This proactive approach helps you address wear, contamination, and other concerns early on.

- Benefits of Oil Analysis:

- Identifies contaminants and wear particles

- Monitors oil condition and effectiveness

- Helps in planning maintenance and reducing downtime

Follow Manufacturer Recommendations

Each piece of equipment has specific oil change intervals and requirements set by the manufacturer. Adhering to these guidelines is essential for optimal performance and to avoid voiding warranties.

- Check Your Manual: Always refer to the operator’s manual for the recommended oil type and change intervals. This ensures that you’re using the correct products and maintaining your equipment according to the manufacturer’s standards.

Quick Tips for Effective Oil Changes

-

Schedule Regular Changes: Set a consistent schedule for oil changes based on hours of operation or seasonal use.

-

Use Quality Products: Invest in high-quality oils and filters to protect your machinery.

-

Keep Records: Document each oil change, including the date, oil type, and any observations. This helps track maintenance history and plan future services.

By making regular oil changes a priority, you can ensure that your agricultural machinery operates efficiently and reliably. This simple maintenance task plays a vital role in extending equipment lifespan and preventing costly breakdowns. Next, we’ll dive into the importance of lubricating moving parts and how it contributes to machinery longevity.

Lubricate Moving Parts

Keeping the moving parts of your agricultural machinery well-lubricated is like giving them a second life. Proper lubrication reduces friction, extends the lifespan, and ensures your equipment runs smoothly. Let’s explore why this is so crucial and how you can do it effectively.

Friction Reduction: The Silent Saver

Friction is the enemy of all machinery. When moving parts rub against each other without the right lubrication, it leads to wear and tear. This can cause parts to degrade quickly, leading to costly repairs or replacements.

- Texas Refinery Corp products are specially designed to combat this issue. Their high-quality lubricants reduce friction and protect your machinery from unnecessary damage.

Lifespan Extension: More Bang for Your Buck

By regularly lubricating moving parts, you not only reduce friction but also extend the lifespan of your equipment. Well-maintained machinery can serve you for years, maximizing your investment and minimizing downtime.

- Why Lifespan Matters:

- Longer equipment life means fewer replacements and savings on new machinery.

- Reduced downtime increases productivity and keeps your operations running smoothly.

Choosing the Right Lubricants

Not all lubricants are created equal. It’s essential to select the right product for your machinery to ensure optimal performance.

- Texas Refinery Corp offers a range of lubricants custom for different types of agricultural equipment. Choosing the right one can make a significant difference in how your machinery performs.

Regular Lubrication Schedule

Setting a regular lubrication schedule is key to maintaining your equipment. Here’s how to keep it simple:

-

Follow Manufacturer Guidelines: Always check your equipment manual for recommended lubrication intervals and products.

-

Create a Lubrication Log: Document each lubrication session, noting the date, type of lubricant used, and any observations.

-

Inspect and Clean: Before lubricating, inspect the parts for any damage or dirt. Clean them thoroughly to ensure the lubricant can do its job effectively.

By prioritizing the lubrication of moving parts, you can ensure that your machinery operates efficiently and lasts longer. This simple maintenance task is an investment in the future of your equipment. Next, we’ll focus on checking all hitches and tires to ensure safety and efficiency in your operations.

Check All Hitches and Tires

Safety and efficiency are paramount when it comes to maintaining agricultural machinery. A key part of this is ensuring that all hitches and tires are in top condition. Let’s explore why this matters and how you can keep these components well-maintained.

Safety First: Hitch Inspections

Hitches are crucial for connecting tractors to trailers and other equipment. A faulty hitch can lead to accidents, causing damage to machinery or even injury.

-

Regular Inspections: Check all hitches for wear, rust, or damage. Ensure they are securely fastened and functioning correctly.

-

Clean Connections: Remove any dirt or debris from hitch components to ensure a tight and safe connection.

-

Routine Checks: Make it a habit to inspect hitches before each use. This simple step can prevent accidents and keep your operations running smoothly.

Tire Inspection: Rolling Towards Efficiency

Tires are the unsung heroes of your farm machinery. Properly maintained tires ensure that your equipment operates efficiently and safely.

-

Tread and Pressure Checks: Regularly inspect tire treads for wear and ensure they are inflated to the recommended pressure. Properly inflated tires improve fuel efficiency and reduce wear on the machinery.

-

Spare Tire Readiness: Always have a fully functional spare tire ready. Regularly check its condition and pressure to avoid unexpected downtime.

-

Signs of Wear: Look for cracks, bulges, or punctures in tires. Addressing these issues early can prevent costly repairs and accidents.

Efficiency Boost: The Benefits of Proper Tire Maintenance

Maintaining your tires not only improves safety but also boosts efficiency. Here’s how:

-

Fuel Savings: Properly inflated tires reduce rolling resistance, leading to better fuel economy.

-

Extended Tire Life: Regular maintenance extends the life of your tires, saving money on replacements.

-

Improved Performance: Well-maintained tires provide better traction and stability, enhancing the overall performance of your machinery.

By prioritizing the maintenance of hitches and tires, you ensure the safety and efficiency of your operations. This proactive approach can prevent accidents and keep your machinery running smoothly. Next, we’ll explore the importance of inspecting vehicle lights and batteries to maintain visibility and functionality.

Inspect Any Lights on the Vehicle and the Batteries

Visibility and functionality are critical for the safe operation of agricultural machinery, especially when you’re working early in the morning or late into the night. Proper maintenance of vehicle lights and batteries ensures you can see and be seen, reducing the risk of accidents.

Light Up Your Path: The Importance of Light Maintenance

Agricultural machinery often operates in low-light conditions. Ensuring all lights are functional is essential for safety.

-

Regular Checks: Inspect brake lights, signal lights, and headlights regularly. Replace any bulbs that are dim or not working to maintain optimal visibility.

-

Clean Lenses: Dirt and grime can reduce the effectiveness of your lights. Clean the lenses regularly to ensure maximum brightness.

-

Test Connections: Loose or corroded connections can cause lights to fail. Regularly inspect and clean connections to ensure all lights work reliably.

Power Up: Maintaining Your Batteries

A well-maintained battery is crucial for the functionality of your machinery. Without it, you might find yourself stuck at the most inconvenient times.

-

Inspect for Corrosion: Corrosion on battery terminals can lead to power loss and stalling. Clean terminals regularly to ensure a strong connection.

-

Check Charge Levels: Regularly test the battery’s charge. A weak battery can fail unexpectedly, leading to downtime.

-

Seasonal Storage Tips: If you have equipment that’s only used seasonally, consider storing the batteries indoors to extend their life. Cold weather can drain battery life, so indoor storage helps maintain charge and longevity.

Stay Ahead: Benefits of Proper Light and Battery Maintenance

Maintaining lights and batteries not only improves safety but also ensures your equipment is always ready to go.

-

Reduced Downtime: By keeping batteries charged and lights functional, you prevent unexpected breakdowns and delays.

-

Improved Safety: Proper lighting ensures you can see clearly and be seen by others, reducing the risk of accidents.

-

Cost Savings: Regular maintenance extends the life of your batteries and lights, saving money on replacements.

By focusing on the maintenance of lights and batteries, you ensure your machinery is ready for any task, day or night. This proactive approach keeps your operations safe and efficient. Next, let’s dig into the importance of calibrating special equipment for accuracy and performance.

Calibrate Special Equipment

Calibrating special equipment isn’t just a routine task; it’s a vital step to ensure accuracy and performance in agricultural operations. Whether you’re using thermometers, scales, or metal detectors, maintaining their precision is key to successful outcomes.

Precision Matters: Why Calibration is Crucial

In farming, even minor inaccuracies can lead to significant issues. For example, an uncalibrated scale might lead to incorrect measurements, impacting yield predictions or livestock feed distribution. Regular calibration ensures your equipment provides reliable data, which is essential for informed decision-making.

-

Improved Accuracy: Regular calibration ensures that your readings are spot-on. This is crucial for operations like pesticide application, where precision can make a difference in crop health.

-

Optimal Performance: Properly calibrated equipment operates at its best, reducing the risk of errors and inefficiencies.

Manufacturer Guidelines: Your Best Friend

Each piece of equipment comes with manufacturer guidelines, which are your go-to resource for calibration. These guidelines provide specific instructions custom to your equipment, ensuring you calibrate correctly without causing damage.

-

Follow Instructions: Always refer to the manufacturer’s manual for calibration steps. Skipping steps or using incorrect methods can lead to inaccuracies.

-

Regular Intervals: Manufacturers often recommend calibration intervals. Sticking to these ensures your equipment remains in top shape.

Benefits of Regular Calibration

The benefits of regular calibration extend beyond just accuracy and performance. They also contribute to the overall efficiency and safety of your farming operations.

-

Reduced Errors: By ensuring your equipment is accurate, you minimize the risk of costly mistakes.

-

Increased Efficiency: Calibrated equipment works more efficiently, saving time and resources.

-

Extended Equipment Life: Regular maintenance, including calibration, helps extend the life of your equipment, maximizing your investment.

By prioritizing the calibration of your special equipment, you ensure that your agricultural operations are precise and productive. This proactive approach not only boosts performance but also safeguards your equipment against potential issues. Next, we’ll explore the importance of keeping machinery clean to prevent corrosion and maintain functionality.

Keep Machinery Clean

Keeping your agricultural machinery clean is more than just an aesthetic choice—it’s a crucial step in corrosion prevention and maintaining functionality. Dirt, debris, and moisture are relentless foes that can lead to rust and other issues if not managed properly.

The Importance of Cleanliness in Machinery

Farm machinery often operates in harsh environments, making it prone to dirt accumulation. Regular cleaning helps prevent these contaminants from causing long-term damage.

-

Corrosion Prevention: Dirt and moisture can accelerate corrosion, particularly on metal parts. This can lead to significant damage if left unchecked. By keeping machinery clean, you protect it from rust and prolong its lifespan.

-

Improved Functionality: Clean machinery operates more efficiently. Dirt can clog filters, obstruct moving parts, and reduce the performance of your equipment. Regular cleaning ensures everything runs smoothly.

Effective Cleaning Methods

Implementing a consistent cleaning routine is essential for maintaining your machinery. Here are some methods to consider:

-

Basic Cleaning: Use a broom to remove loose debris like grass or hay from equipment surfaces. This simple step can prevent build-up that might cause more significant issues later.

-

Pressure Washing: For more thorough cleaning, a pressure washer can be highly effective. It can reach areas that are difficult to clean manually, ensuring all dirt and grime are removed.

-

Use Appropriate Detergents: When necessary, use detergents specifically designed for agricultural equipment to avoid damaging sensitive parts. Always follow the manufacturer’s recommendations regarding cleaning products.

Best Practices for Cleaning

Following best practices helps ensure that cleaning is both effective and safe for your machinery.

-

Regular Intervals: Clean your machinery at regular intervals, especially after heavy use or at the end of a season. This habit helps prevent long-term damage.

-

Inspect While Cleaning: Cleaning is an excellent opportunity to inspect your machinery for signs of wear or damage. Look for loose parts, cracks, or unusual wear patterns.

-

Protective Measures: After cleaning, consider applying a protective coating to metal parts to prevent rust. This extra step can significantly extend the life of your equipment.

By prioritizing cleanliness, you not only prevent corrosion but also maintain the functionality and efficiency of your machinery. This proactive approach ensures your equipment remains reliable and ready for the tasks ahead. Next, we’ll discuss the importance of inspecting for damage to catch issues early and keep your operations running smoothly.

Inspect for Damage

Regular inspections are a key part of agricultural machinery maintenance. They help identify damage early, allowing for proactive repairs that keep your equipment running smoothly. Ignoring potential issues can lead to costly breakdowns and increased downtime, which no farmer can afford.

Identifying Damage Signs

When inspecting your machinery, look for common damage signs that might indicate underlying problems:

-

Cracks and Fractures: Check metal and plastic parts for any visible cracks. These can lead to structural failures if not addressed promptly.

-

Leaks: Inspect hydraulic systems and engines for any signs of fluid leakage. Leaks can indicate worn seals or damaged hoses, leading to performance issues.

-

Unusual Noises: Listen for any unusual sounds during operation. Grinding, squealing, or knocking noises can be early indicators of mechanical problems.

-

Wear and Tear: Examine belts, hoses, and other moving parts for excessive wear. Worn components can lead to inefficient operation and eventual failure.

Proactive Repairs

Once damage is identified, proactive repairs are essential to prevent minor issues from becoming major problems:

-

Immediate Action: Address any identified issues immediately. Delaying repairs can lead to more extensive damage and costly repairs.

-

Use Quality Parts: When replacing damaged components, use high-quality parts that meet the manufacturer’s specifications. This ensures compatibility and longevity.

-

Document Repairs: Keep detailed records of all repairs and maintenance activities. This documentation helps track the condition of your equipment over time and can be crucial for warranty claims.

Regular Maintenance Checks

Incorporating regular maintenance checks into your routine can help catch issues early and extend the life of your machinery:

-

Scheduled Inspections: Set a schedule for regular inspections, such as monthly or seasonally, depending on usage. Consistent checks help catch issues before they escalate.

-

Checklists: Use a maintenance checklist to ensure all critical components are inspected. This systematic approach reduces the risk of overlooking potential problems.

-

Team Training: Train your team to recognize signs of damage and perform basic inspections. A well-informed team can identify issues early, preventing costly downtime.

By routinely inspecting for damage and addressing issues proactively, you safeguard your machinery’s performance and reliability. This approach not only extends the lifespan of your equipment but also ensures your operations remain efficient and productive. Next, we’ll explore the benefits of storing your equipment indoors to protect it from the elements and further extend its lifespan.

Store Equipment Indoors When Possible

Storing your agricultural machinery indoors is a simple yet effective way to protect your investment. The benefits are clear: weather protection, lifespan extension, and efficient storage solutions.

Weather Protection

Outdoor elements can be harsh on machinery. Rain, snow, and UV rays can cause rust, corrosion, and fading, which degrade the equipment over time. By keeping your machinery indoors, you shield it from these damaging factors. Think of your garage or barn as a protective shield against the unpredictable weather.

Lifespan Extension

Keeping equipment indoors doesn’t just protect it from the weather; it also significantly extends its lifespan. Regular exposure to the elements can lead to premature wear and tear. By storing machinery inside, you reduce the risk of moisture-induced rust and sun damage, which can weaken materials and shorten the life of your equipment.

Storage Solutions

If indoor storage space is limited, consider these alternatives:

-

Temporary Shelters: Use tarps or portable garages as temporary solutions. They provide basic protection from rain and sun.

-

Overhangs: Install overhangs or lean-tos on existing structures. These offer a practical way to shield machinery from direct weather exposure.

-

Custom Sheds: Invest in custom-built sheds designed to fit your specific machinery. These can be a long-term solution that offers optimal protection.

Storing equipment indoors or under protective covers is a small effort that pays off in the long run. It not only maintains the performance and appearance of your machinery but also saves money on repairs and replacements. Next, we’ll discuss why modifying engines can be risky and how to avoid voiding warranties.

Avoid Customizing or Modifying Engines

Modifying engines might seem like a way to get more power or better efficiency from your agricultural machinery. However, this can lead to serious performance risks and other unintended consequences.

Warranty Voiding

One of the biggest risks of modifying engines is voiding your warranty. Manufacturers often have strict guidelines on what can and cannot be altered. When you modify an engine, you risk losing the warranty protection that covers repairs and replacements. This means any future issues will come out of your pocket.

Performance Risks

Beyond warranty concerns, engine modifications can lead to performance issues. Modern machinery is equipped with complex systems that are finely tuned. Altering them can disrupt the balance and lead to inefficiencies or even damage. For instance, changing the engine’s software or hardware could result in overheating, reduced fuel efficiency, or increased wear and tear on parts.

Manufacturer Advice

Before considering any modifications, it’s crucial to consult the manufacturer’s advice. Manufacturers design equipment with specific performance standards in mind. They provide guidelines to ensure optimal operation and longevity. Ignoring these can compromise the reliability of your machinery.

If you’re looking to improve performance, consider these manufacturer-approved alternatives:

- Regular Maintenance: Keep up with scheduled maintenance to ensure your machinery is running at peak performance.

- Upgrades: Some manufacturers offer official upgrades that improve performance without voiding warranties.

- Consult Professionals: If you’re unsure, consult with authorized technicians who can provide insights and recommendations.

By adhering to manufacturer guidelines and avoiding unauthorized modifications, you can maintain your machinery’s integrity and ensure it operates smoothly for years to come.

Next, we’ll explore how leveraging technology can streamline maintenance and improve efficiency.

Leveraging Technology for Maintenance

In today’s agricultural world, using technology to manage agricultural machinery maintenance is more important than ever. One of the most effective tools available is a Computerized Maintenance Management System (CMMS). This software can revolutionize how you handle maintenance tasks, making your operations more efficient and less prone to costly downtime.

CMMS: A Game Changer for Maintenance Management

A CMMS helps organize and track all aspects of maintenance. By centralizing data, farmers can easily access equipment histories, schedule tasks, and monitor repairs. This system reduces the guesswork and ensures that every piece of machinery receives the attention it needs at the right time.

With a CMMS, you can:

- Automate Maintenance Schedules: Set reminders for regular tasks like oil changes and inspections. This automation ensures nothing is overlooked, keeping your machinery in top shape.

- Track Maintenance Histories: Easily view past repairs and services. This information helps identify patterns or recurring issues, allowing for proactive solutions.

- Manage Inventory: Keep tabs on spare parts and supplies. A CMMS alerts you when stock is low, preventing delays caused by missing components.

Efficiency Through Technology

Implementing a CMMS can significantly boost efficiency. It provides real-time updates, allowing you to make informed decisions quickly. For instance, if a tractor breaks down, you can immediately see its service history and determine the best course of action.

Additionally, a CMMS fosters better communication within your team. Technicians can update repair statuses, add comments, and even upload photos. This transparency keeps everyone informed and reduces the risk of miscommunication.

The Future of Maintenance

As technology continues to evolve, so too will the capabilities of systems like CMMS. Future advancements may include more predictive analytics, helping farmers anticipate issues before they arise. This proactive approach will further decrease downtime and increase productivity.

By embracing technology in maintenance management, farmers can ensure their operations run smoothly and efficiently. This not only saves time and money but also extends the lifespan of valuable equipment.

Next, we’ll dig into proactive maintenance strategies that can further improve the reliability of your machinery.

Proactive Maintenance Strategies

Proactive maintenance is all about staying ahead of potential problems. In farming, this means keeping your machinery running smoothly and efficiently. By focusing on preventive maintenance, regular inspections, and proper lubrication, you can avoid unexpected breakdowns and extend the lifespan of your equipment.

Preventive Maintenance: The First Line of Defense

Preventive maintenance involves taking steps to prevent machinery failures before they happen. This means regularly checking and servicing equipment according to a set schedule. It’s like getting a health check-up for your machines. By doing this, you spot small issues before they become big problems.

Key Benefits of Preventive Maintenance:

- Reduces Downtime: Scheduled maintenance means fewer unexpected repairs. This keeps your equipment running when you need it most.

- Saves Money: Catching issues early can save on costly repairs and replacements.

- Increases Safety: Well-maintained machines are safer to operate, reducing the risk of accidents.

Regular Inspections: Keeping an Eye on the Details

Inspections are a vital part of proactive maintenance. By routinely examining your equipment, you can identify wear and tear or potential issues. Make it a habit to check crucial components like belts, hoses, and filters.

Inspection Tips:

- Use a Checklist: A standardized checklist ensures you don’t miss anything during inspections.

- Document Everything: Keep records of each inspection. This helps track the condition of your machinery over time.

- Involve Your Team: Train your team to perform basic inspections. This empowers them to spot issues early.

Lubrication: The Lifeblood of Machinery

Lubrication reduces friction and wear on moving parts. Without it, your machinery can suffer from increased wear and tear, leading to breakdowns. Make sure to use high-quality lubricants, like those from Texas Refinery Corp, to ensure optimal performance.

Lubrication Best Practices:

- Follow Manufacturer Guidelines: Use the recommended type and amount of lubricant for each piece of equipment.

- Set a Schedule: Regularly lubricate parts based on their usage and condition.

- Check for Leaks: Inspect seals and joints for leaks to prevent lubricant wastage.

By incorporating these proactive maintenance strategies, you can significantly improve the reliability and efficiency of your farm machinery. This not only saves time and money but also ensures your equipment is always ready for the demands of farming.

Up next, we’ll explore how utilizing farm equipment management software can further improve your maintenance efforts.

Utilizing Farm Equipment Management Software

In today’s agricultural world, using farm equipment management software is like having a superpower for your machinery maintenance. It helps you keep track of everything, work better with your team, and get updates in real-time.

Maintenance Tracking Made Easy

Gone are the days of scribbling notes in a dusty notebook or trying to remember when the last oil change was. With farm equipment management software, you can track all maintenance activities in one place. This means you know exactly what’s been done and what needs attention.

Benefits of Maintenance Tracking:

– Comprehensive Records: Have a clear history of all maintenance tasks, service logs, and repairs.

– Reminders and Alerts: Get notified about upcoming maintenance tasks to prevent any oversight.

– Data-Driven Decisions: Use historical data to identify patterns and make informed maintenance decisions.

Boosting Team Collaboration

A challenge in farm maintenance is ensuring everyone is on the same page. With the right software, team collaboration becomes seamless. Whether you’re in the field or at the office, everyone can access the same information.

Ways to Improve Team Collaboration:

– Real-Time Updates: Share updates instantly, so everyone knows the current status of equipment.

– Task Assignments: Easily assign maintenance tasks to team members and track their progress.

– Communication Tools: Use built-in messaging features to discuss issues or share insights.

Real-Time Updates for Better Management

Imagine knowing the status of every piece of equipment at any moment. Real-time updates make this possible, allowing you to act quickly and efficiently.

Advantages of Real-Time Updates:

– Immediate Action: Quickly respond to any issues that arise, minimizing downtime.

– Live Monitoring: Keep an eye on equipment performance and maintenance needs as they happen.

– Transparency: Everyone involved can see what’s happening, reducing misunderstandings and delays.

By leveraging farm equipment management software, you streamline your maintenance processes, improve team collaboration, and stay ahead of potential issues. This means less downtime, lower costs, and a more productive farming operation.

In the next section, we’ll dive into frequently asked questions about agricultural machinery maintenance to further clarify how you can optimize your maintenance strategy.

Frequently Asked Questions about Agricultural Machinery Maintenance

What is agricultural machinery maintenance?

Agricultural machinery maintenance involves regular checks and repairs to keep farm equipment running smoothly. This includes tasks like oil changes, lubrication, and inspections to catch issues early. Keeping machines in top shape helps prevent breakdowns and ensures they work efficiently when needed most.

Why is regular maintenance important?

Regular maintenance is crucial for several reasons:

- Prevent Downtime: A well-maintained machine is less likely to break down, which means fewer delays during critical farming periods like planting or harvest.

- Extend Equipment Life: Routine care, such as lubrication and checking for wear, can extend the life of your machinery.

- Improve Safety: Regular inspections help identify potential hazards, ensuring a safer environment for farm workers.

- Cost Savings: Preventive maintenance can reduce the need for costly repairs and replacements.

How can technology aid in maintenance?

Technology plays a vital role in modern agricultural machinery maintenance. Here’s how it helps:

- Centralized Data: Maintenance management software like CMMS (Computerized Maintenance Management Systems) organizes all your maintenance records in one place.

- Real-Time Monitoring: Sensors and IoT devices can monitor equipment performance and alert you to issues before they become serious.

- Efficient Scheduling: Software can help plan and schedule maintenance tasks, ensuring nothing is overlooked.

- Improved Collaboration: Digital tools allow teams to share updates and communicate effectively, keeping everyone informed and aligned.

Using technology not only streamlines maintenance processes but also improves the overall efficiency and productivity of your farming operations.

Conclusion

At CFAB Global, we understand that agricultural machinery maintenance is crucial to keeping your farm running smoothly. Our approach is centered around the Machine Reliability Program, which is designed to ensure your equipment operates at its best. This program provides personalized solutions to boost the performance and lifespan of your machinery, reducing downtime and improving productivity.

Why Choose CFAB Global?

-

Expertise and Support: With years of experience, our team is dedicated to providing top-tier support custom to your needs. We work closely with you to understand your unique challenges and deliver solutions that make a difference.

-

Customized Solutions: Our Machine Reliability Program is not a one-size-fits-all approach. We customize our services to fit your specific machinery requirements, ensuring optimal performance and longevity.

-

Proactive Maintenance: We focus on predictive maintenance strategies to prevent breakdowns before they occur. This proactive approach helps you avoid costly repairs and keeps your operations running smoothly.

By partnering with CFAB Global, you’re not just maintaining your equipment; you’re investing in the future success of your farm. Our commitment to excellence and customized solutions makes us the go-to partner for agricultural machinery support.

For more information on how CFAB Global can improve your agricultural operations, visit our agricultural equipment page. Let us help you maximize your machinery’s potential and drive your farm’s productivity to new heights.