Adjustable hydraulic flow divider technology is revolutionizing how industries manage fluid flow in machinery. This equipment takes a single fluid stream and splits it into multiple streams with precise control and consistency. Key benefits include:

- Precision: Ensures each outlet maintains a consistent flow ratio, regardless of changes in the inlet flow.

- Efficiency: Improves machinery performance by optimizing fluid distribution based on operational needs.

- Versatility: Models available, such as the FP53 and FP56, cater to varying requirements, from single outlet adjustment to dual stream control.

An adjustable hydraulic flow divider stands out in its ability to maintain steady distribution, even under changing conditions. This precision leads to better operational efficiency and reduced equipment downtime. For companies seeking solutions to improve machinery performance and reliability, this technology is invaluable. At CFAB Global, we’re at the forefront, offering advanced solutions like these to lift industry standards.

I’m Todd Cleppe, the CEO of CFAB Global, drawing from over 25 years of expertise in machinery and process improvements. Having designed systems that slashed equipment failures by 40%, I understand the value of innovations like the adjustable hydraulic flow divider in boosting productivity.

Quick adjustable hydraulic flow divider definitions:

– how does a hydraulic flow divider valve work

– hydraulic priority flow divider

Understanding Hydraulic Flow Dividers

Hydraulic flow dividers are essential components in many industrial systems. They are designed to split a single stream of hydraulic fluid into two or more streams. This is crucial for machinery that requires precise control of fluid distribution.

The Basics of Hydraulic Flow Dividers

At their core, hydraulic flow dividers use a predefined ratio to ensure that each output stream receives a specific percentage of the input flow. This is particularly important in applications where balance and synchronization between different parts of a machine are necessary.

For example, in a construction vehicle with multiple hydraulic arms, a flow divider ensures each arm moves at the correct speed, regardless of changes in load or pressure elsewhere in the system.

Key Components and Functionality

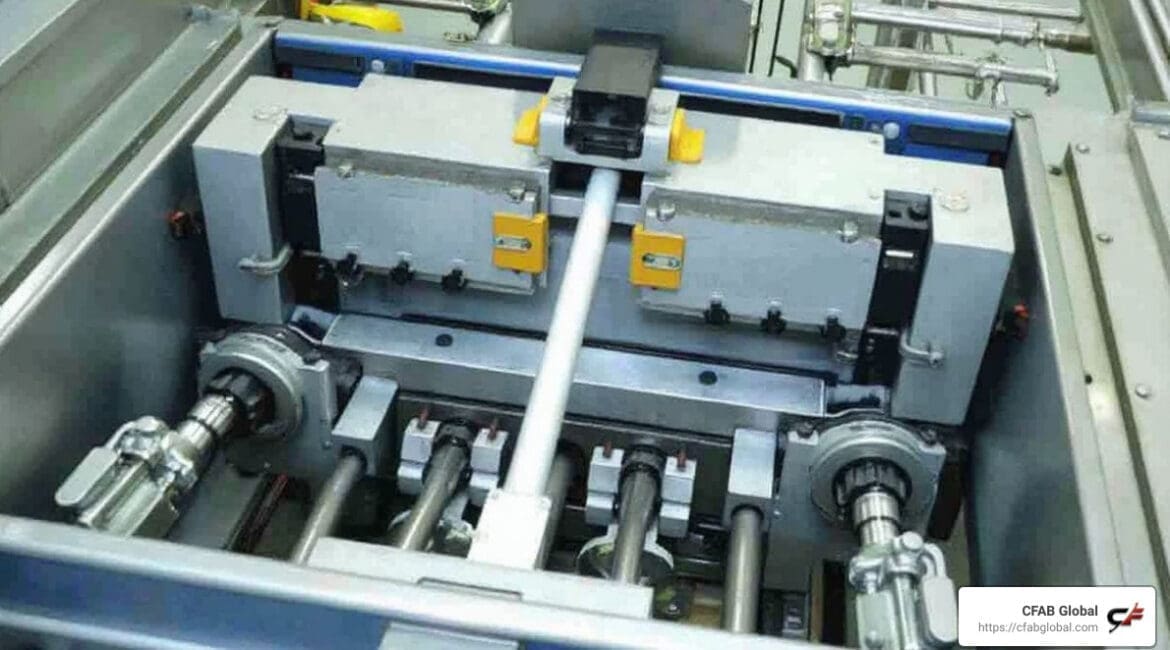

Hydraulic flow dividers typically consist of gears or rotary mechanisms that divide the incoming fluid. These components are robust and designed to handle high pressures and varying viscosities of hydraulic oils.

-

Gears in Series: Many flow dividers use gears arranged in series. As fluid passes through, the gears rotate, splitting the flow into separate paths. This mechanism is reliable and maintains the predefined ratio even when the fluid’s viscosity changes.

-

Precision and Accuracy: The accuracy of a hydraulic flow divider is crucial. It must maintain the set ratio even as conditions change. The Brand FP Series, for example, allows users to adjust the flow to one or both outlets, ensuring precision in various scenarios.

Applications and Advantages

Hydraulic flow dividers are used in a variety of industries, from manufacturing to agriculture. They offer several advantages:

-

Improved Efficiency: By ensuring each part of a machine receives the correct amount of fluid, flow dividers help optimize performance and reduce energy waste.

-

Improved Control: Operators can adjust the flow to meet specific operational needs, which is invaluable in processes that require fine-tuned control.

-

Reduced Wear and Tear: By evenly distributing hydraulic fluid, flow dividers help prevent excessive stress on any one part of a system, reducing maintenance needs and prolonging equipment life.

In summary, hydraulic flow dividers are vital for systems that require precise fluid management. They ensure balanced operation, improve efficiency, and reduce wear on machinery. At CFAB Global, we understand the importance of these components and offer advanced solutions to meet the evolving needs of our clients.

Top Adjustable Hydraulic Flow Dividers

FP Series

The FP Series of adjustable hydraulic flow dividers by Brand Hydraulics includes models FP53, FP55, and FP56. These dividers are designed to take a single stream of hydraulic fluid and split it into two separate streams. The standout feature of the FP Series is its adjustability.

-

FP53 and FP55: These models allow users to adjust the flow to one of the outlets, making them ideal for applications where one stream needs more precise control. Whether you’re operating heavy machinery or complex industrial equipment, the ability to fine-tune the flow ensures that each component gets exactly what it needs.

-

FP56: This model takes it a step further by allowing adjustments to both outlet flows. This dual adjustability is particularly useful in systems where both output streams need to be precisely controlled to maintain balance and efficiency.

One of the key benefits of the FP Series is that the initial flow settings remain stable even if the workload on one stream is significantly higher than on the other. This consistency is crucial for maintaining system stability and performance.

PRINCE Model RD-500

The PRINCE Model RD-500 is another excellent example of an adjustable hydraulic flow divider. It functions similarly to the PRINCE Model RD-400 but with a significant improvement: adjustable priority flow.

This model allows users to set the priority flow anywhere between 2 GPM and 12 GPM using an adjusting screw. Once set, the flow can be locked in place, ensuring that the preferred setting remains constant even during operation. This feature is particularly beneficial in field applications where conditions can change rapidly, and precise adjustments are necessary.

The RD-500 is designed for constant volume applications, ensuring that the priority flow remains consistent regardless of changes in the overall system flow. This makes it an ideal choice for systems that require a specific flow rate to a critical component, such as a hydraulic motor or actuator.

Both the FP Series and the PRINCE Model RD-500 showcase the versatility and precision of modern adjustable hydraulic flow dividers. By offering adjustable flows, these models provide the flexibility needed to optimize hydraulic systems for a wide range of applications.

How to Adjust a Hydraulic Flow Divider

Adjusting an adjustable hydraulic flow divider is a straightforward process, but it requires attention to detail to ensure accuracy and efficiency. Here’s a simple guide to help you make the necessary adjustments:

- Using a Pressure Gauge:

Begin by connecting a pressure gauge to the system. This tool is crucial for monitoring the pressure levels and ensuring that the flow divider is operating within the desired parameters. Accurate pressure readings help in fine-tuning the flow settings to match the specific requirements of your hydraulic system.

- Locknut Adjustment:

Find the locknut on the flow divider. The locknut is used to secure the adjustment setting once the desired flow rate is achieved. Before making any changes, loosen the locknut. This will allow the adjustment mechanism to move freely as you set the flow rate.

- Hexagonal Set Screw:

The hexagonal set screw is the component you’ll adjust to change the flow rate. Using a hex key, turn the set screw clockwise to decrease the flow or counterclockwise to increase it. Make small adjustments and observe the changes in the system’s performance through the pressure gauge.

- Lock in the Setting:

Once you’ve achieved the desired flow rate, tighten the locknut to secure the set screw in place. This step is crucial to prevent any unintended changes to the flow settings during operation.

- Recheck the System:

After adjusting and locking the settings, recheck the system with the pressure gauge. Ensure that the flow divider is maintaining the correct pressure and flow rate. This final check helps confirm that the adjustments have been made accurately.

By following these steps, you can effectively adjust your hydraulic flow divider to meet the specific demands of your application. Whether you’re managing a complex industrial system or a simple hydraulic setup, these adjustments ensure that your system runs smoothly and efficiently.

Benefits of Using Adjustable Hydraulic Flow Dividers

Adjustable hydraulic flow dividers offer several key benefits, making them essential components in hydraulic systems. Let’s explore the main advantages: accuracy, division accuracy, and oil viscosity.

Precision and Accuracy

One of the standout benefits of using an adjustable hydraulic flow divider is the precision it brings to fluid management. These devices ensure that the fluid flow is divided accurately, which is crucial for systems that rely on balanced distribution. Whether you’re operating heavy machinery or delicate processing equipment, maintaining a precise flow is vital for optimal performance.

Consistent Division Accuracy

Division accuracy refers to the ability of the flow divider to maintain a consistent ratio between the output streams. This feature is particularly important in applications where one stream may be doing more work than the other. The FP series, including models like FP53, FP55, and FP56, are designed to keep the flow ratio constant, even when the input flow varies. This consistency helps in maintaining system stability and efficiency.

Handling Oil Viscosity Variations

Adjustable flow dividers are engineered to handle changes in oil viscosity, which can occur due to temperature fluctuations or different types of hydraulic fluids. This adaptability ensures that the flow divider maintains its performance across a range of operating conditions. By accommodating these variations, adjustable flow dividers prevent potential disruptions in the system, promoting smooth and reliable operation.

In conclusion, the benefits of using adjustable hydraulic flow dividers extend beyond mere fluid distribution. They play a critical role in enhancing system accuracy, ensuring consistent division, and managing oil viscosity changes effectively. These advantages make them indispensable in various hydraulic applications, from industrial machinery to precision engineering systems.

Frequently Asked Questions about Hydraulic Flow Dividers

How to adjust a hydraulic flow divider?

Adjusting a hydraulic flow divider is straightforward but requires attention to detail. The process typically involves a pressure gauge, a locknut, and a hexagonal set screw. Here’s how it works:

-

Install a Pressure Gauge: Attach a pressure gauge to monitor the hydraulic system’s pressure during adjustments. This ensures you’re within safe operating limits.

-

Loosen the Locknut: The locknut secures the set screw in place. Loosening it allows you to make adjustments to the flow rate.

-

Adjust the Hexagonal Set Screw: Turn the hexagonal set screw to increase or decrease the flow to the desired level. This step requires precision to ensure the flow is set correctly.

-

Re-tighten the Locknut: Once the adjustment is made, re-tighten the locknut to secure the set screw and maintain the setting.

This process ensures that your flow divider is calibrated to meet specific system requirements, enhancing performance and efficiency.

Are hydraulic flow dividers accurate?

Hydraulic flow dividers are known for their division accuracy. They maintain a precise ratio between the output streams, even when conditions change. This accuracy is vital in applications where one stream may need to perform more work than the other.

The accuracy of a flow divider can be influenced by oil viscosity. Variations in viscosity, due to temperature changes or different fluid types, can affect how the flow is divided. However, high-quality flow dividers are designed to compensate for these changes, maintaining consistent performance.

How does a hydraulic flow divider work?

A hydraulic flow divider operates by using gears in series to split a single stream of hydraulic fluid into multiple streams. The gears are arranged to ensure a predefined ratio of flow between the output channels.

Here’s a simplified breakdown:

- Input: Hydraulic fluid enters the divider through a single inlet.

- Gears in Series: The fluid passes through a series of gears. These gears are precisely machined to divide the flow into the desired ratio.

- Predefined Ratio: The gears ensure that the flow is split according to a predefined ratio, which remains constant even if the input flow varies.

This mechanism allows hydraulic systems to operate efficiently by ensuring that each part of the system receives the correct amount of fluid, maintaining balance and performance.

Understanding these mechanisms and adjustments is crucial for anyone working with hydraulic systems. Proper use and maintenance of flow dividers can significantly improve system reliability and efficiency.

Conclusion

At CFAB Global, we understand that operational efficiency is the cornerstone of any successful business. Our Machine Reliability Program is designed to optimize the performance and lifespan of critical machinery components, ensuring that your operations run smoothly with minimal downtime.

We offer custom solutions for industries ranging from manufacturing to agriculture, each crafted to meet specific needs and challenges. Our approach is not one-size-fits-all; we work closely with clients to design strategies that deliver measurable results. By focusing on predictive maintenance and proactive strategies, we help businesses maximize their return on investment.

Our expertise extends to adjustable hydraulic flow dividers, essential components in many hydraulic systems. These devices ensure precision and efficiency by maintaining a constant flow ratio, even under varying conditions. With CFAB Global’s support, businesses can leverage the full potential of their hydraulic systems, enhancing productivity and reducing operational costs.

For those seeking to lift their machinery’s performance, our partnership with Graco Inc. ensures access to top-tier equipment and solutions. Trust CFAB Global to be your partner in achieving operational excellence. Whether it’s through our Machine Reliability Program or our comprehensive range of services, we are committed to supporting your success every step of the way.