An adjustable flow divider plays a crucial role in hydraulic systems. Designed to receive a single fluid stream and divide it into two, its primary function is to ensure precision control over how fluid moves through hydraulic machinery. Key benefits include maintaining a steady flow ratio, even when the workload on individual streams varies. This reliability makes the adjustable flow divider an essential tool in both industrial and mobile applications.

- Purpose: Divide fluid flow while allowing control over output streams.

- Consistency: Keeps the ratio of divided flows stable, regardless of load changes.

- Usage: Widely used in sectors like manufacturing, agriculture, and construction for efficient hydraulic operations.

I’m Todd Cleppe, CEO & Co-Founder at CFAB Global, with over 25 years in designing automated systems that improve machinery efficiency. My experience with adjustable flow divider technology helps companies minimize downtime and extend equipment life, ensuring smooth and reliable hydraulic processes.

Know your adjustable flow divider terms:

– 3 way flow divider

– hydraulic priority flow divider

– flow divider valves

Understanding Adjustable Flow Dividers

Types of Flow Dividers

When it comes to adjustable flow dividers, understanding the different types is key. Primarily, they are categorized into two main types: motor type and orifice type.

-

Motor Type Flow Dividers: These use hydraulic motors connected by a common shaft. As fluid flows into the motor, it turns the shaft, dividing the flow into separate streams. This type is highly effective for applications requiring precise synchronization, such as in hydraulic motors driving multiple wheels.

-

Orifice Type Flow Dividers: These rely on orifices to split the fluid flow. The size of the orifice determines the flow rate for each stream. They are simpler in design compared to motor types and are often used in systems where less precise control is acceptable.

Both types offer unique advantages, with the choice largely depending on the specific requirements of the hydraulic system.

How Adjustable Flow Dividers Work

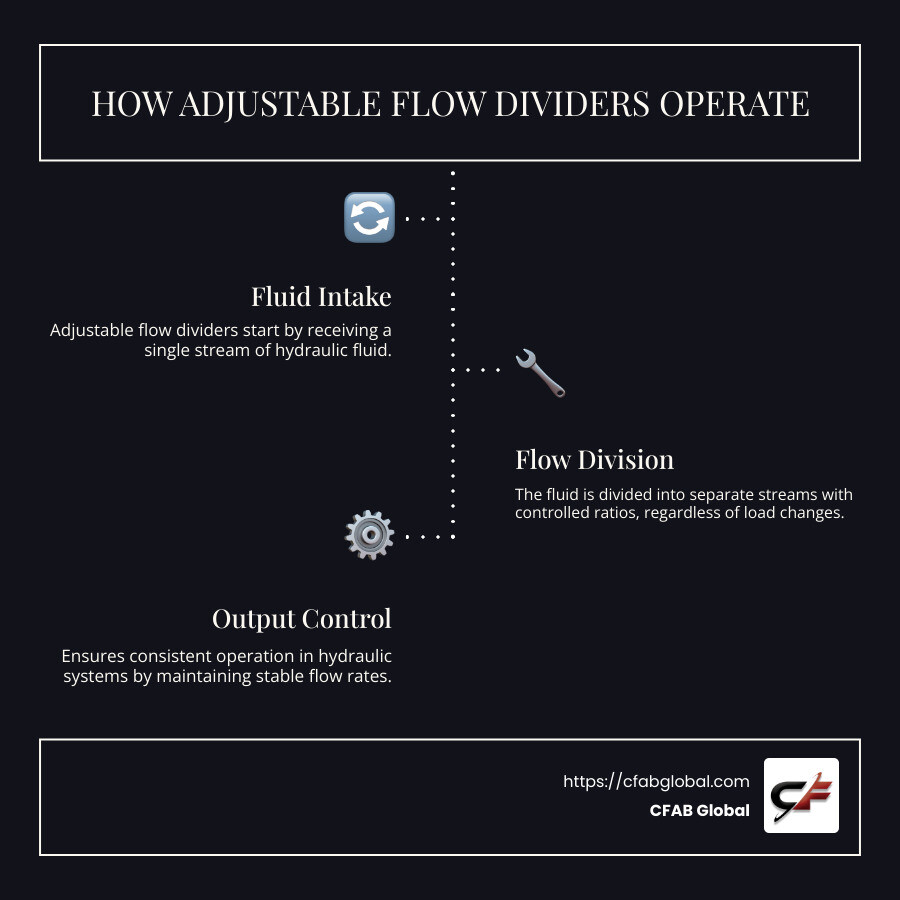

At the heart of an adjustable flow divider is its ability to control hydraulic fluid streams. Here’s how they operate:

-

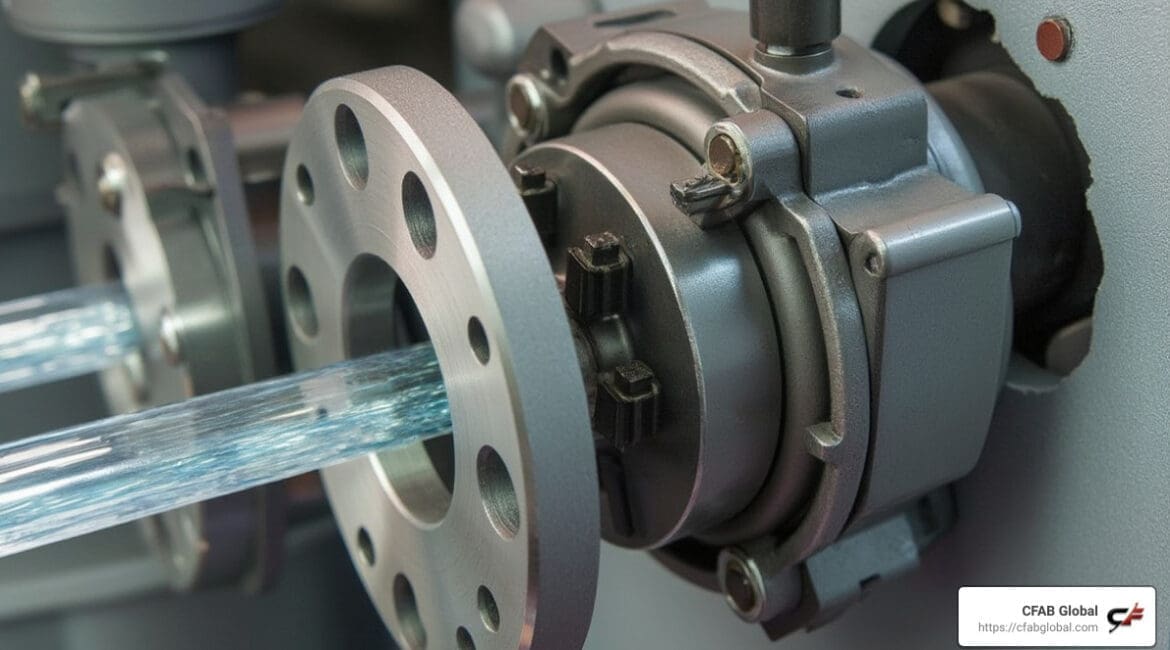

Fluid Flow and Needle Valve: The fluid enters the divider through a main inlet. A needle valve within the system allows for fine adjustments of the flow rate. By turning the needle valve, the user can control the exact amount of fluid that passes through each outlet.

-

Flow Rate Control: Once the needle valve is set, the flow divider maintains a constant flow rate to each stream, even if the total input flow changes. This is crucial for applications where consistent operation is necessary, regardless of varying load demands.

-

Pressure Compensation: Some models, like the FP series, come with built-in pressure compensation. This feature ensures that the division of fluid remains stable, despite fluctuations in pressure. It’s particularly useful in dynamic environments where pressure can vary significantly.

By understanding these components and how they interact, users can effectively use adjustable flow dividers to optimize hydraulic systems.

Adjustable flow dividers are indispensable in managing hydraulic circuits efficiently. Whether you are working with heavy machinery in construction or delicate operations in manufacturing, these devices ensure that fluid distribution is accurate and reliable.

Key Features of Adjustable Flow Dividers

Popular Models and Specifications

Adjustable flow dividers are celebrated for their versatility and precision in controlling hydraulic systems. They ensure constant volume distribution, maintain pressure compensation, and offer precise flow control. Let’s explore some popular models and their specifications to understand their unique capabilities.

FP Series: FP53, FP55, FP56

The FP series, which includes the FP53, FP55, and FP56 models, is renowned for its ability to divide a single fluid stream into two adjustable streams. This feature is particularly beneficial when different work outputs are required simultaneously.

- FP53 and FP55: These models allow adjustment of one outlet flow, ideal for systems where one stream requires variable flow while the other remains constant.

- FP56: This model offers the flexibility to adjust both outlet flows, providing improved control over the hydraulic system.

All models maintain a consistent flow ratio even when the inlet flow varies, making them reliable in fluctuating conditions.

PFD-30

The PFD-30 model is designed for applications demanding high precision. It splits the input flow into two or more streams while maintaining constant volume distribution. This model is perfect for complex hydraulic circuits where precise flow control is crucial.

RD-500

The RD-500 is an adjustable constant volume priority divider, offering a priority flow adjustable from 2 GPM to 12 GPM. The priority flow is set using an adjusting screw, which is then locked to maintain the setting. This model is excellent for field applications requiring fine-tuning of flow rates to meet specific operational needs.

Pressure compensation in these models ensures that the flow division remains stable, even when pressure fluctuates. This is crucial in dynamic environments like construction and agriculture, where pressure changes are common.

By understanding the specifications and capabilities of these popular models, users can select the right adjustable flow divider to optimize their hydraulic systems, ensuring efficiency and reliability across various applications.

Applications of Adjustable Flow Dividers

Industry-Specific Uses

Adjustable flow dividers are integral components in numerous industries, thanks to their ability to manage hydraulic circuits with precision. These devices split a single hydraulic flow into multiple streams, allowing for priority flow and bypass flow management. This ensures that critical operations receive the necessary fluid power, while excess flow can be diverted elsewhere or returned to the reservoir.

Manufacturing

In manufacturing, adjustable flow dividers are used to control machinery that requires precise fluid power. For instance, they can regulate the speed of hydraulic motors in assembly lines, ensuring synchronized operation of multiple machines. This is vital for maintaining production efficiency and product quality.

Construction

Construction equipment, such as excavators and cranes, often rely on hydraulic systems that benefit from flow dividers. These devices enable simultaneous operation of multiple hydraulic functions, such as moving the boom and rotating the cab. By prioritizing flow to essential functions and managing bypass flow, construction machinery operates smoothly and efficiently.

Agriculture

In the agriculture sector, adjustable flow dividers are used in equipment like tractors and harvesters. They control the hydraulic flow to different implements, such as plows and seeders, ensuring each receives the right amount of power. This precision improves the effectiveness of agricultural operations, leading to better crop yields.

Energy

The energy industry, particularly in oil and gas, uses adjustable flow dividers to manage complex hydraulic systems. These systems often involve multiple operations that require precise flow control, such as drilling and pipeline management. By ensuring priority flow to critical functions, these dividers help maintain safety and efficiency in energy production.

In each of these industries, the reliability and flexibility of adjustable flow dividers make them indispensable. By enabling precise control over hydraulic circuits, they improve operational efficiency and ensure that critical functions receive the necessary power. This adaptability is key to meeting the diverse needs of various sectors, from manufacturing to energy.

Frequently Asked Questions about Adjustable Flow Dividers

How does a flow divider work?

A flow divider is a crucial component in hydraulic systems. It splits a single input flow into multiple output streams, delivering fluid to different parts of a machine. This is typically achieved using hydraulic motors mounted on a common shaft. As the fluid enters, the motors rotate, evenly distributing the flow to each outlet. This setup ensures that each part of the system receives the precise amount of fluid it requires, even if the demands on each outlet vary.

What are the different types of flow dividers?

Flow dividers come in various types, each suited to specific applications:

-

Motor Type: These use hydraulic motors to divide the flow. They are often used when high accuracy and efficiency are needed. The motors ensure that the flow is evenly split, regardless of load changes in the system.

-

Orifice Type: These dividers use simple orifices to split the flow. While they are less complex and generally cheaper, they may not offer the same level of precision as motor types. They are suitable for systems where exact flow division is not critical.

How accurate is a rotary flow divider?

Rotary flow dividers are known for their precision. They often incorporate electro-proportional valves, which allow for fine-tuned control over the flow rates. This technology adjusts the flow based on real-time feedback, ensuring that each outlet receives the exact amount of fluid required. The accuracy of these systems is essential in applications where even minor discrepancies in fluid distribution can lead to significant issues, such as in manufacturing or energy production.

In summary, adjustable flow dividers are versatile tools in hydraulic systems, offering precise flow management through various types, such as motor and orifice types. Their accuracy, especially in rotary models with electro-proportional valves, makes them indispensable in industries requiring precise hydraulic control.

Conclusion

At CFAB Global, we understand the importance of precision and reliability in hydraulic systems. Our commitment to excellence is reflected in our Machine Reliability Program, which is designed to boost the performance and lifespan of critical machinery components. By integrating solutions like adjustable flow dividers, we help businesses across industries improve their operational efficiency and productivity.

Our Machine Reliability Program is not just a service—it’s a partnership. We work closely with each client to create a custom strategy that meets their unique needs. From initial consultation to ongoing support, we ensure that your equipment operates at peak performance, reducing costly downtime and maximizing return on investment.

Whether you’re in manufacturing, construction, agriculture, or energy, CFAB Global offers the expertise and solutions you need to succeed. Our team of specialists is dedicated to providing the highest level of support, ensuring that your machinery is always ready to meet the demands of your industry.

For more information on how CFAB Global can improve your operations, explore our Machine Reliability Program.

Choose CFAB Global for reliable machinery solutions that drive productivity and efficiency. We’re committed to your success, every step of the way.