4 way flow divider is a crucial component in hydraulic systems that allows you to split fluid flow evenly between multiple paths, ensuring synchronized operation of connected machinery. If you need to synchronize different hydraulic cylinders or motors, a 4 way flow divider is essential:

- Equal flow distribution: Ensures balanced pressure and flow to multiple actuators.

- Improved system control: Improves accuracy and efficiency in complex hydraulic tasks.

- Reliable performance: Designed to handle high pressures securely.

- Customizable applications: Suitable for various machinery and industrial needs.

A 4 way flow divider is a type of hydraulic control device designed to manage the distribution of hydraulic fluid across multiple outlets. This device improves operational efficiency by evenly splitting the flow of hydraulic fluid, ensuring that all connected equipment operates in unison. Its ability to provide proportional division makes it indispensable for systems requiring high accuracy and control, ensuring effective performance across various industrial applications.

My name is Todd Cleppe, and with over 25 years in engineering and machinery operations, I’ve spent my career focusing on solutions like the 4 way flow divider. Through my work at CFAB Global, I’ve leveraged engineering innovations to significantly improve the efficiency and reliability of machinery across multiple sectors.

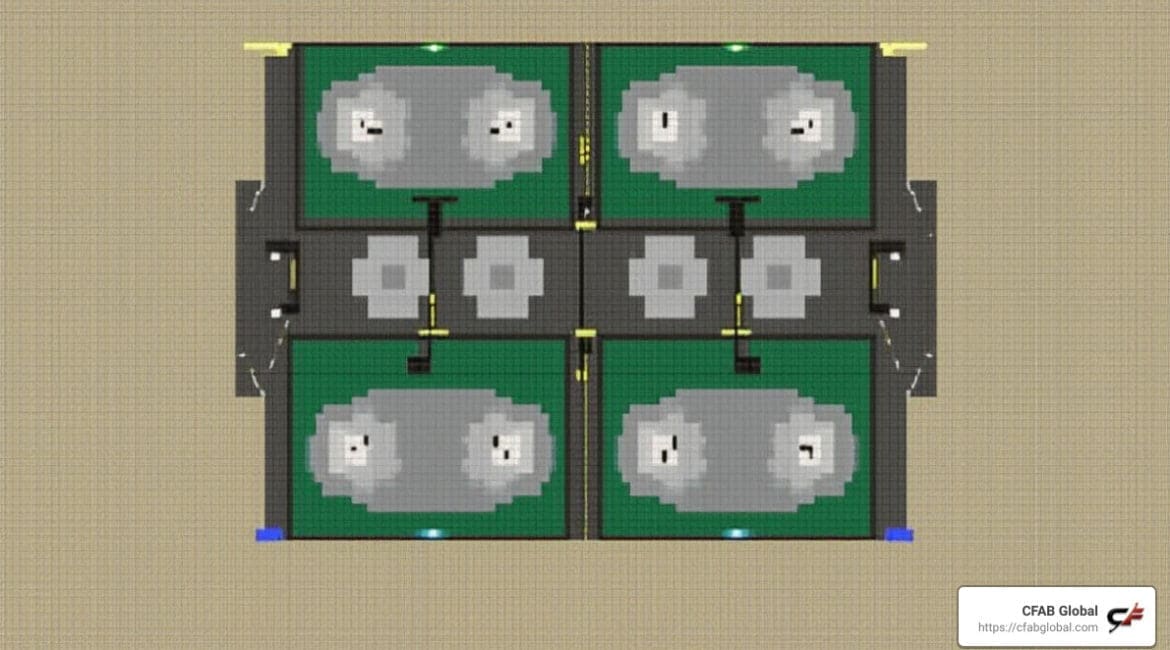

This infographic outlines the key functions of a 4 way flow divider, showcasing its role in synchronizing machinery and improving system control.

Quick look at 4 way flow divider:

– flow divider valves

– adjustable hydraulic flow divider

– hydraulic priority flow divider

Understanding 4 Way Flow Dividers

When it comes to hydraulic systems, 4 way flow dividers play a pivotal role in managing fluid distribution. They ensure that machinery operates smoothly and efficiently by splitting hydraulic fluid into multiple paths. Let’s dig into the two primary types of flow dividers: motor type and orifice type.

Motor Type Flow Dividers

Motor type flow dividers are equipped with hydraulic motors and a common shaft. These dividers are designed to split the flow by using multiple hydraulic motors connected to a single shaft. Each motor receives an equal portion of the fluid, ensuring synchronized operation across different parts of the system.

- Hydraulic Motors: These are the driving force behind motor type flow dividers. They convert hydraulic energy into mechanical energy, facilitating the even distribution of fluid.

- Common Shaft: The common shaft connects all the motors, ensuring they rotate together and maintain synchronized flow to each outlet.

This design is particularly effective in applications where precise synchronization is crucial, such as in machinery with multiple moving parts that must operate in harmony.

Orifice Type Flow Dividers

Orifice type flow dividers, on the other hand, rely on fixed or adjustable orifices to control the flow paths. These dividers work by directing the hydraulic fluid through specific paths, using orifices to regulate the flow rate to each outlet.

- Flow Paths: The fluid is divided into different paths, each controlled by an orifice. This allows for precise flow management, ensuring each path receives the correct amount of fluid.

- Hydraulic Pump: The pump pushes the fluid through the divider, where it is split into the designated paths.

Orifice type flow dividers are ideal for systems where varying flow rates are needed. They provide flexibility and control, making them suitable for complex hydraulic systems.

Both motor type and orifice type flow dividers are integral to maintaining efficiency and accuracy in hydraulic operations. By understanding the distinct features and applications of each type, you can choose the right 4 way flow divider for your needs, ensuring optimal performance in your hydraulic systems.

In the next section, we’ll explore how these dividers work to synchronize multiple cylinders and distribute pump output proportionally, enhancing the overall efficiency of hydraulic systems.

How 4 Way Flow Dividers Work

Synchronizing Multiple Cylinders

In hydraulic systems, achieving synchronized operation across multiple cylinders is crucial for smooth and efficient machinery function. 4 way flow dividers are designed to accomplish this by splitting the hydraulic fluid evenly among the cylinders. This ensures that each cylinder operates in unison, preventing misalignment or uneven force distribution.

- Hydraulic Motors and Common Inlet: The flow divider uses hydraulic motors connected to a common inlet. This setup allows the motors to receive equal amounts of hydraulic fluid, ensuring that all cylinders move at the same pace. The common inlet is key to maintaining synchronization, as it provides a steady and uniform flow to each motor.

By using a 4 way flow divider, systems can achieve precise coordination, which is particularly important in applications like lifting equipment or industrial machinery where multiple cylinders must work together seamlessly.

Proportional Division of Pump Output

Another significant function of 4 way flow dividers is the proportional division of pump output. This feature is essential for distributing hydraulic fluid to various parts of a system in precise proportions, based on the specific needs of each component.

-

Differential Pressure Relief and High-Pressure Seals: These dividers are equipped with differential pressure relief valves and high-pressure seals. The pressure relief valves ensure that if one path faces resistance, the excess pressure is safely managed, preventing damage to the system. High-pressure seals maintain the integrity of the divider, even under intense pressure conditions, ensuring reliable performance.

-

Flow Pressure Management: By controlling the flow pressure, these dividers can adjust the fluid distribution, ensuring that each outlet receives the exact amount of fluid required for optimal operation. This is particularly beneficial in systems where different components need varying flow rates to function correctly.

The ability to proportionally divide pump output not only improves the efficiency of hydraulic systems but also extends the life of the machinery by preventing overloading and uneven wear.

In the next section, we’ll dig into the benefits of using 4 way flow dividers, including how they improve system accuracy and boost operational efficiency.

Benefits of Using 4 Way Flow Dividers

Enhancing System Accuracy

When it comes to hydraulic systems, precision is paramount. 4 way flow dividers play a crucial role in enhancing system accuracy by ensuring that hydraulic fluid is distributed evenly across multiple components. This is particularly important in applications where synchronized movement is necessary, such as in industrial machinery or lifting equipment.

-

Rotary Flow Dividers: These devices are designed to provide consistent fluid distribution, which helps maintain alignment and balance among cylinders. By using rotary flow dividers, systems can achieve a higher level of precision, minimizing the risk of mechanical failures due to uneven force distribution.

-

Electro-Proportional Valves: Incorporating electro-proportional valves in flow dividers allows for even finer control of hydraulic fluid distribution. These valves adjust the flow rate dynamically, responding to changes in system demand, which improves the overall accuracy and responsiveness of the machinery.

Boosting Operational Efficiency

Efficiency is a key factor in any hydraulic system, and 4 way flow dividers are instrumental in boosting it. By optimizing fluid distribution, these dividers help reduce downtime and increase productivity.

-

Reduce Downtime: One of the main advantages of using flow dividers is their ability to prevent system overloads and mechanical failures. By ensuring that each component receives the correct amount of fluid, flow dividers help maintain the integrity of the system, reducing the likelihood of breakdowns and the associated downtime.

-

Increase Productivity: With improved fluid control, machinery can operate at optimal levels, leading to increased productivity. By maintaining consistent performance, flow dividers enable systems to handle more demanding tasks without compromising on efficiency.

Incorporating 4 way flow dividers into your hydraulic system not only improves precision and efficiency but also extends the lifespan of your machinery. This makes them an essential component for industries that rely on reliable and high-performing hydraulic systems.

In the next section, we’ll address some frequently asked questions about these versatile devices, helping you understand their various types and how they work.

Frequently Asked Questions about 4 Way Flow Dividers

What are the different types of flow dividers?

When it comes to flow dividers, there are two primary types: motor type and orifice type.

-

Motor Type Flow Dividers: These use hydraulic motors connected by a common shaft. As the fluid flows through the system, the motors help synchronize the movement of different components. This type ensures that each part of the system receives an equal and precise flow, making it ideal for applications requiring synchronized operations.

-

Orifice Type Flow Dividers: These rely on fixed or adjustable orifices to divide the flow. They are simpler in design compared to motor type dividers. Orifice type is often used when the application does not require perfect synchronization but still needs a reliable division of flow.

How does a flow divider work?

A flow divider operates by distributing hydraulic fluid from a single pump to multiple outlets, ensuring each receives the correct amount of fluid. This is particularly crucial in systems that use hydraulic motors connected by a common shaft. The flow divider ensures that the motors operate in unison, preventing any one motor from running faster or slower than the others. This synchronization is vital for maintaining balance and efficiency in machinery.

How accurate is a rotary flow divider?

Rotary flow dividers are known for their high accuracy in distributing hydraulic fluid. They use a series of gears or rotors to ensure equal division of flow. This type of flow divider is especially effective in applications where precision is key, such as in industrial machinery that requires exact movements.

Incorporating electro-proportional valves can improve the accuracy of rotary flow dividers even further. These valves adjust the flow rate dynamically, responding to real-time changes in system demand. This capability allows for fine-tuning of hydraulic fluid distribution, ensuring that each component receives the precise amount needed for optimal performance.

Understanding these aspects of flow dividers can significantly improve your hydraulic system’s performance, making them an invaluable component in many industrial applications.

Conclusion

At CFAB Global, we understand the critical role that 4 way flow dividers play in enhancing hydraulic system performance. Our commitment to providing advanced machinery solutions is reflected in our comprehensive offerings, including the highly regarded Machine Reliability Program.

CFAB Global’s Machine Reliability Program is designed to maximize the performance and lifespan of your machinery. By focusing on predictive maintenance and custom strategies, we help businesses reduce downtime and improve operational efficiency. This program is not just about fixing issues—it’s about preventing them before they occur, ensuring your equipment runs smoothly and reliably.

Our expertise spans multiple industries, from manufacturing to agriculture, where precise hydraulic control is essential. Whether you’re looking to synchronize operations or achieve proportional flow division, our solutions are crafted to meet your unique needs.

With CFAB Global as your partner, you gain access to a team of specialists dedicated to enhancing your machinery’s reliability and productivity. We work closely with you to deliver customized support and cutting-edge equipment that align with your business objectives.

For those in the food packaging and processing sector, we also recommend exploring BE Machinery’s solutions for advanced equipment that meets high hygiene standards.

If you’re looking to lift your hydraulic systems with 4 way flow dividers and other innovative solutions, explore our services to see how we can help you achieve your goals. At CFAB Global, we’re committed to your success, providing the tools and expertise you need to thrive.