Essential Equipment for Snack Food Manufacturing

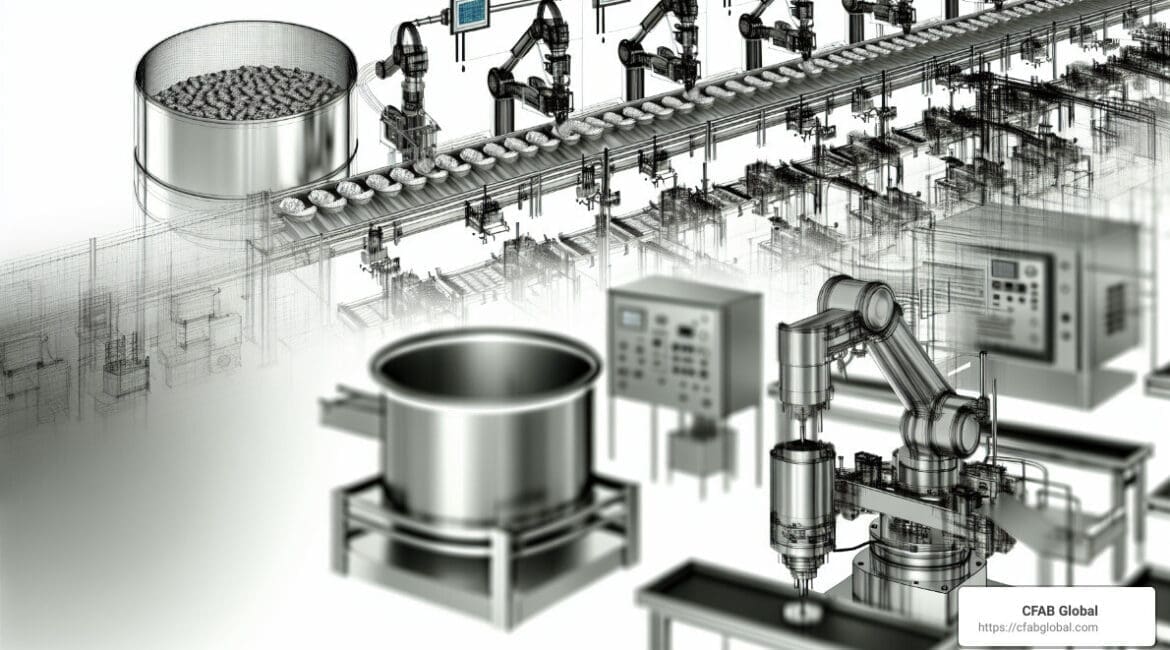

When it comes to setting up a successful snack food manufacturing operation, knowing the essential equipment is crucial. Here’s a quick food manufacturing equipment list to get you started:

1. Preparation Equipment:

– Washing Systems

– Peelers

– Graders

– Sorting Machines

2. Size Reduction Equipment:

– Grinders

– Crushers

– Mills

– Slicers

3. Homogenization and Emulsification Equipment:

– Homogenizers

– Emulsifiers

– Colloid Mills

4. Specialized Snack Food Processing Equipment:

– Extruders

– Ovens

– Fryers

– Seasoning Machines

5. Packaging Equipment:

– Sealing Machines

– Wrapping Machines

– Labeling and Coding Machines

Snack food manufacturing involves various stages of processing and packaging to ensure high-quality, safe, and appealing products. From slicing and dicing to mixing, blending, and seasoning, the right equipment can significantly boost productivity and efficiency. Moreover, proper packaging equipment ensures the freshness and safety of snack foods, meeting industry standards and consumer expectations.

My name is Todd Cleppe, Executive Engineer and Sales at CFAB LLC, specializing in automated lubrication systems and food packaging equipment. With over 25 years of experience in the field, I have a deep understanding of the food manufacturing equipment list and how to optimize machinery for snack food production.

Basic Food Manufacturing Equipment

Slicing, Dicing, and Chopping Equipment

When it comes to snack food manufacturing, slicing, dicing, and chopping are foundational processes. These tasks transform raw ingredients into manageable pieces for further processing. The equipment used for these operations includes slicers, dicers, choppers, shredders, and crushers.

- Slicers are essential for cutting ingredients into uniform slices. Whether it’s vegetables for chips or meat for jerky, slicers ensure consistency and speed.

- Dicers cut ingredients into cubes or smaller pieces. They’re perfect for preparing fruits and vegetables for salads or toppings.

- Choppers are versatile and can handle a variety of ingredients, from nuts to herbs, making them indispensable in any snack food production line.

- Shredders are used for breaking down ingredients into fine pieces. Think of shredded cheese or cabbage for coleslaw.

- Crushers are vital for breaking down harder materials like nuts or seeds into smaller, more manageable pieces.

CFAB Global offers top-of-the-line slicing, dicing, and chopping equipment. Our machines are designed to meet high standards of hygiene and efficiency, ensuring your production line runs smoothly.

Mixing and Blending Equipment

Mixing and blending are crucial steps in snack food production. They ensure that ingredients are evenly distributed, resulting in a consistent final product. The key equipment here includes mixers, blenders, and dough processors.

- Mixers are used to combine ingredients thoroughly. Whether you’re making a dough or a mixture for snacks, a good mixer ensures even distribution.

- Blenders are perfect for creating smooth, uniform mixtures. They’re often used for making sauces, batters, and other liquid-based products.

- Dough Processors are specialized mixers designed for dough preparation. They handle the heavy-duty mixing required for bread, pastry, and other dough-based snacks.

CFAB Global excels in providing high-quality mixers and blenders. Our equipment is built to handle various food processing tasks, ensuring that your ingredients are mixed to perfection every time.

For more information on how CFAB Global can improve your snack food production, visit our website.

Specialized Snack Food Processing Equipment

To create delicious and consistent snack foods, specialized equipment is essential. Let’s explore some of the key machines used in this process.

Extruders and Forming Equipment

Extruders are vital for shaping snack foods like chips, puffs, and cereal bars. They push raw ingredients through a die to create specific shapes and textures.

Forming machines, sheeters, and laminators are also crucial. These machines help in shaping dough or mixtures into uniform pieces, whether they are flat sheets or layered products.

CFAB Global offers top-notch extruders and forming equipment. Our machines are designed for precision and reliability, ensuring your snack foods are consistently shaped and textured.

Ovens, Dryers, and Fryers

Ovens, dryers, and fryers are essential for cooking and drying snack foods. They ensure that snacks are cooked evenly and have the right texture.

- Ovens: Ideal for baking snacks like crackers and cookies.

- Dryers: Used for removing moisture from products like dried fruit.

- Fryers: Essential for making crispy snacks like potato chips and fried snacks.

CFAB Global provides high-quality ovens, dryers, and fryers that ensure consistent cooking results. Our equipment is designed to maintain the perfect temperature and cooking time for your snack foods.

Seasoning and Coating Machines

Seasoning machines and coating machines add flavor and texture to snack foods. They ensure that every piece is evenly coated with spices, salts, or other flavorings.

Enrobing machines are used for coating snacks with chocolate or other coatings, making them perfect for sweet treats.

CFAB Global offers advanced seasoning and coating machines. Our equipment ensures that your snacks are evenly flavored and coated, providing a consistent and delicious product every time.

Food Manufacturing Equipment List

When it comes to snack food manufacturing, having the right equipment is crucial. Here’s a detailed look at the essential machinery you need, from raw material preparation to size reduction and homogenization.

Raw Material Preparation Equipment

Before you can start making snacks, you need to prepare your raw materials. This involves cleaning, peeling, grading, and sorting.

-

Washing Systems: These are essential for removing dirt and contaminants. Examples include ultrasonic cleaners and spray washers.

-

Peelers: Equipment like Carborundum abrasive rollers and pressure vessels help remove inedible skins from fruits and vegetables.

-

Graders: These machines, such as image processors and tungsten lights, assess the quality of raw materials.

-

Sorting Machines: Sorting equipment like AMFEC 610 Screw Loader and FPEC 327 SL Transfer Conveyor classify raw materials based on size and quality.

Size Reduction Equipment

Once your raw materials are prepped, you’ll need to reduce them to the desired size. This is where grinders, crushers, mills, and slicers come in.

-

Grinders: These machines break down solid materials into smaller pieces. They’re commonly used for meats and grains.

-

Crushers: Crushers, like those used in peanut butter production, reduce large chunks into smaller, manageable pieces.

-

Mills: These are used for fine grinding and pulverizing. They are essential for creating smooth pastes and powders.

-

Slicers: Equipment like the AMFEC BC 200 Incline Conveyor is perfect for cutting vegetables and fruits into uniform slices.

Homogenization and Emulsification Equipment

To achieve a consistent texture and blend ingredients smoothly, you’ll need homogenizers, emulsifiers, and colloid mills.

-

Homogenizers: These machines break down particles to create a uniform mixture. They’re essential for dairy products and sauces.

-

Emulsifiers: Used to mix liquids that normally don’t blend, like oil and water. These are crucial for salad dressings and mayonnaise.

-

Colloid Mills: These machines grind and mix ingredients to produce smooth, homogenous products. They’re perfect for making peanut butter and other spreads.

Next, we’ll dive into the packaging equipment for snack foods, covering everything from sealing to labeling machines.

Packaging Equipment for Snack Foods

When it comes to snack foods, packaging is just as important as the product itself. Proper packaging ensures freshness, extends shelf life, and makes your snacks more appealing to consumers. Let’s explore the key equipment needed for effective snack food packaging.

Sealing and Wrapping Machines

Sealing machines play a crucial role in keeping snack foods fresh. These machines seal bags, pouches, and other containers to prevent air and moisture from spoiling the product. Popular options include:

- Heat Sealers: These use heat to melt and seal the packaging material.

- Impulse Sealers: These generate heat only when the sealing bar is pressed, making them energy-efficient.

- Continuous Band Sealers: Ideal for high-volume operations, these machines seal bags as they move along a conveyor belt.

Wrapping machines are also essential for snack foods. They wrap products in films or foils, providing an additional layer of protection. Common types include:

- Flow Wrappers: These machines wrap products in a continuous film, ideal for items like granola bars.

- Shrink Wrappers: These use heat to shrink a plastic film tightly around the product, offering a tamper-evident seal.

Vacuum packers are another vital piece of equipment. They remove air from the packaging before sealing, which significantly extends the product’s shelf life. These are especially useful for snacks that are prone to oxidation, like nuts and chips.

CFAB Global offers a range of sealing and wrapping solutions designed to meet the highest standards of hygiene and efficiency.

Labeling and Coding Equipment

Once your snack foods are sealed and wrapped, the next step is labeling and coding. This equipment ensures that your products are properly identified and compliant with regulations.

Labeling machines apply labels to packaging, providing essential information like ingredients, nutritional facts, and brand logos. Types of labeling machines include:

- Pressure-Sensitive Labelers: These machines use adhesive labels that stick to the packaging material.

- Sleeve Labelers: These apply shrink sleeves that conform to the shape of the package when heated.

- Wrap-Around Labelers: Ideal for cylindrical packages, these machines wrap labels around the entire product.

Coding machines print important information directly onto the packaging, such as batch numbers, expiry dates, and barcodes. Options include:

- Inkjet Printers: These are versatile and can print on a variety of surfaces.

- Laser Coders: These use laser technology to etch information onto the packaging, offering permanent and tamper-proof coding.

CFAB Global provides cutting-edge labeling and coding equipment that ensures your snack foods are correctly labeled and traceable.

Frequently Asked Questions about Food Manufacturing Equipment

What are the basic food production equipment?

When it comes to food production, there are a few key pieces of equipment that almost every facility will need:

- Slicers, dicers, and choppers: These machines are crucial for cutting ingredients into uniform sizes. They ensure consistency and speed in the production process.

- Mixers and blenders: Used for combining ingredients to create uniform mixtures. Whether you’re making dough, batter, or a blended product, mixers and blenders are essential.

What materials are used in food processing equipment?

Food processing equipment needs to be made from materials that are safe, durable, and easy to clean. Common materials include:

- Plastic materials: Used in parts of machines that require flexibility and lightweight properties.

- UHMW (Ultra High Molecular Weight Polyethylene): Known for its high impact strength and resistance to wear.

- HDPE (High-Density Polyethylene): Offers good chemical resistance and is commonly used in food processing applications.

- Acetal: Known for its strength, hardness, and low friction, making it ideal for precision parts in machinery.

What are the examples of food manufacturing equipment?

There are many types of equipment used in food manufacturing, each serving a specific purpose:

- Bowl choppers: These are used for finely chopping and emulsifying meat and other ingredients.

- Meat slicers: Essential for cutting meat into thin, uniform slices.

- Dough processors: These machines mix and knead dough to the perfect consistency for baking.

- Seafood preparation tools: Include machines for scaling, filleting, and portioning fish and other seafood.

By understanding these basics, you can better equip your snack food production line with the right tools to ensure efficiency and quality.

Next, we’ll dive deeper into the specific types of equipment used in packaging snack foods.

Conclusion

At CFAB Global, we are committed to helping you optimize your snack food manufacturing process. Our Machine Reliability Program is designed to improve productivity, reduce downtime, and extend the lifespan of your machinery.

Productivity is crucial in the competitive snack food industry. By ensuring your equipment is well-maintained and operating at peak efficiency, you can meet production targets and maintain high-quality standards. Our program includes regular maintenance checks and updates to keep your machines running smoothly.

Reducing downtime is another key benefit of our program. Unplanned breakdowns can be costly and disruptive. With proactive maintenance and quick response times, we help minimize these interruptions, ensuring your production line stays on track.

Lastly, extending machinery lifespan is essential for maximizing your investment. Our team of experts provides the necessary support and guidance to keep your equipment in top condition, allowing you to get the most out of your machinery for years to come.

For more information on how we can assist with your food manufacturing needs, visit our Equipment Installation page.

By partnering with CFAB Global, you can focus on what you do best—creating delicious snack foods—while we take care of the rest.